Combustor for boiler

A technology for burners and boilers, which is applied in the direction of combustion ignition, combustion methods, lighting and heating equipment, etc. It can solve the problems of short circuit of insulating layer signal lines, many auxiliary parts, and large volume of mechanical switches, so as to achieve stable position feedback signal and convenient operation. The effect of installation and inspection, reducing maintenance investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

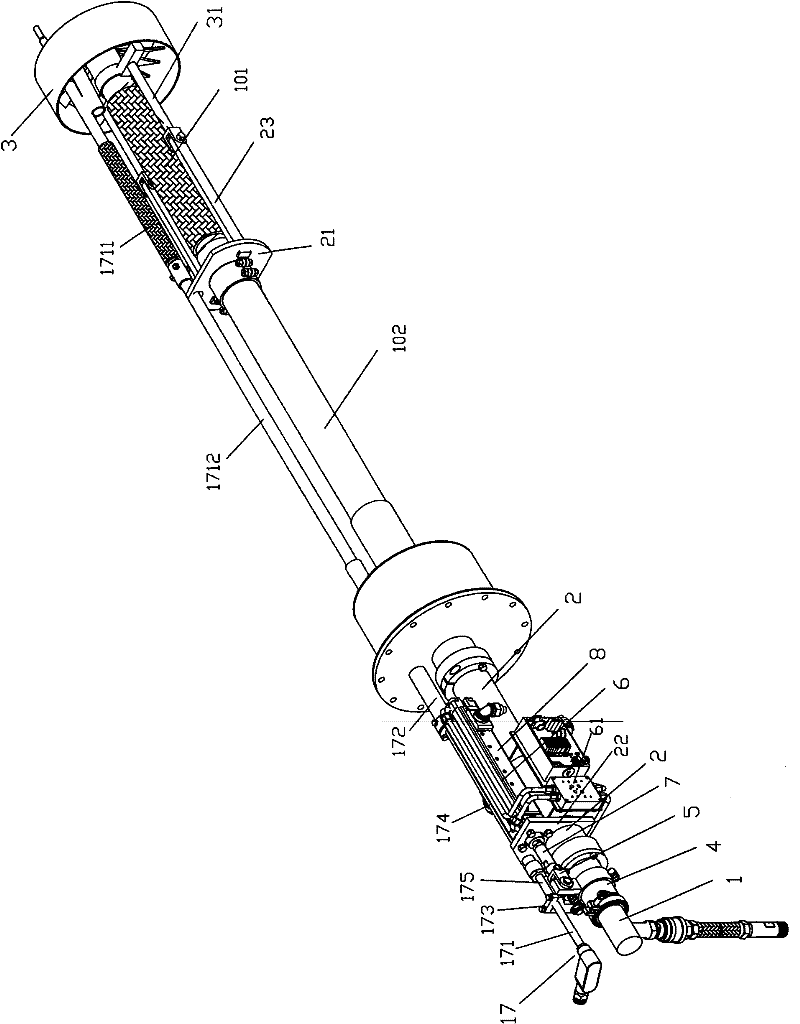

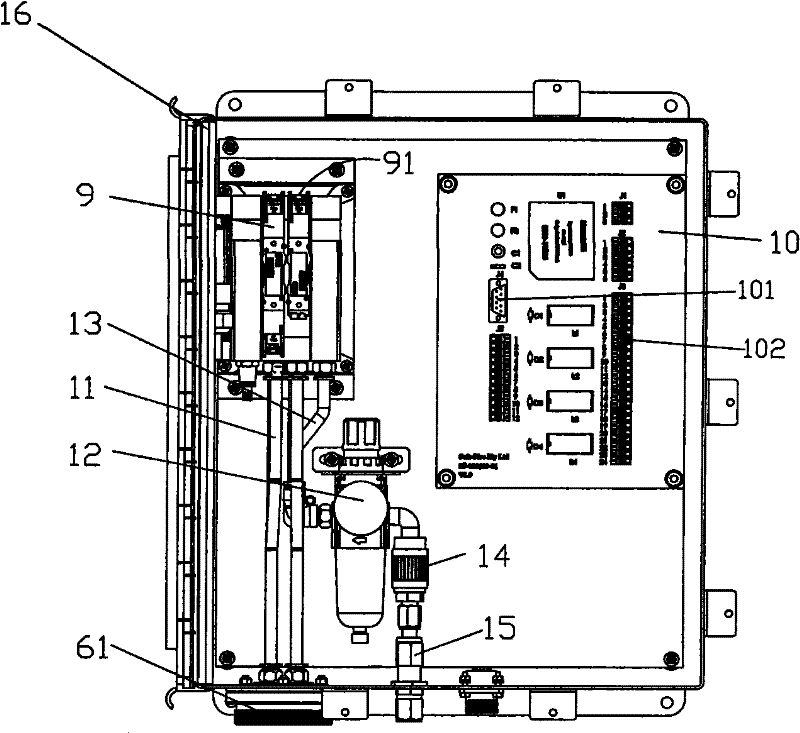

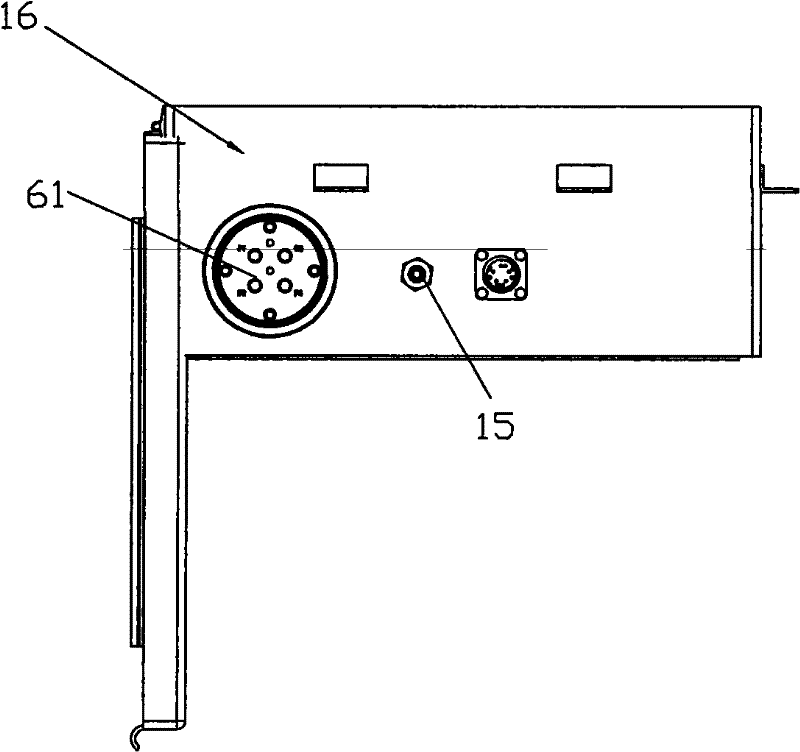

[0027] see figure 1 , figure 2 , image 3 , the boiler burner of the present invention comprises, oil gun gun body 1, and an outer casing 2 is arranged at the gun body rear portion; Stable combustion cover 3 is arranged on the end of oil gun gun body 1; On the rear part of the body 1, in the outer casing 2; the manipulator 5 is arranged on the traction pipe 4; the oil gun cylinder 6, the cylinder piston of the oil gun cylinder 6 is connected with the manipulator 5 through the pull rod 7; The gas source disc 61 of the source; the travel switch 8 is connected to the oil gun cylinder 6; a fixed plate 21, 22 is arranged on the described outer sleeve 2, and the fixed plate 21 is provided with two fixed rods 23 on one side of the front end of the gun body 1; The gun cylinder 6 is connected to the fixed plate 22; two connecting rods 31 are arranged on the stable combustion cover 3, and the connecting rods 31 and the fixed rod 23 on the outer casing 2 fixed plate 21 are hinged by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com