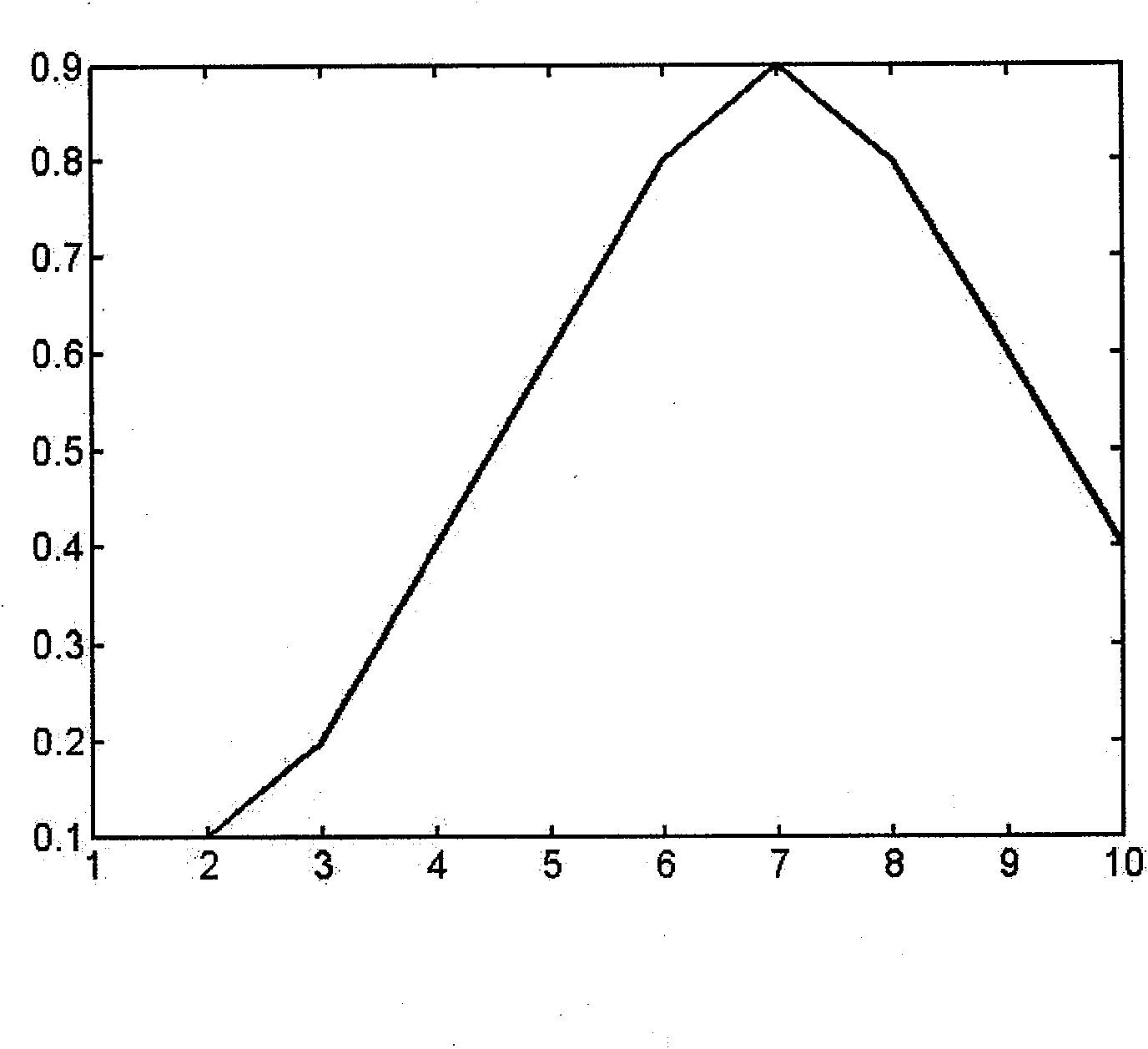

Method for detecting bin level based on image entropy

A detection method and material level detection technology, which is applied in the detection field of silo material level, can solve problems such as difficult to achieve long-term and stable detection, difficulty in auto-focusing of digital cameras, high humidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention is further described as follows with reference to accompanying drawing in conjunction with embodiment:

[0068] Taking the underground coal bunker of a coal mine as an example, the height of the coal bunker is 40m, the diameter is 8m, and the detection accuracy is required to be 0.25m.

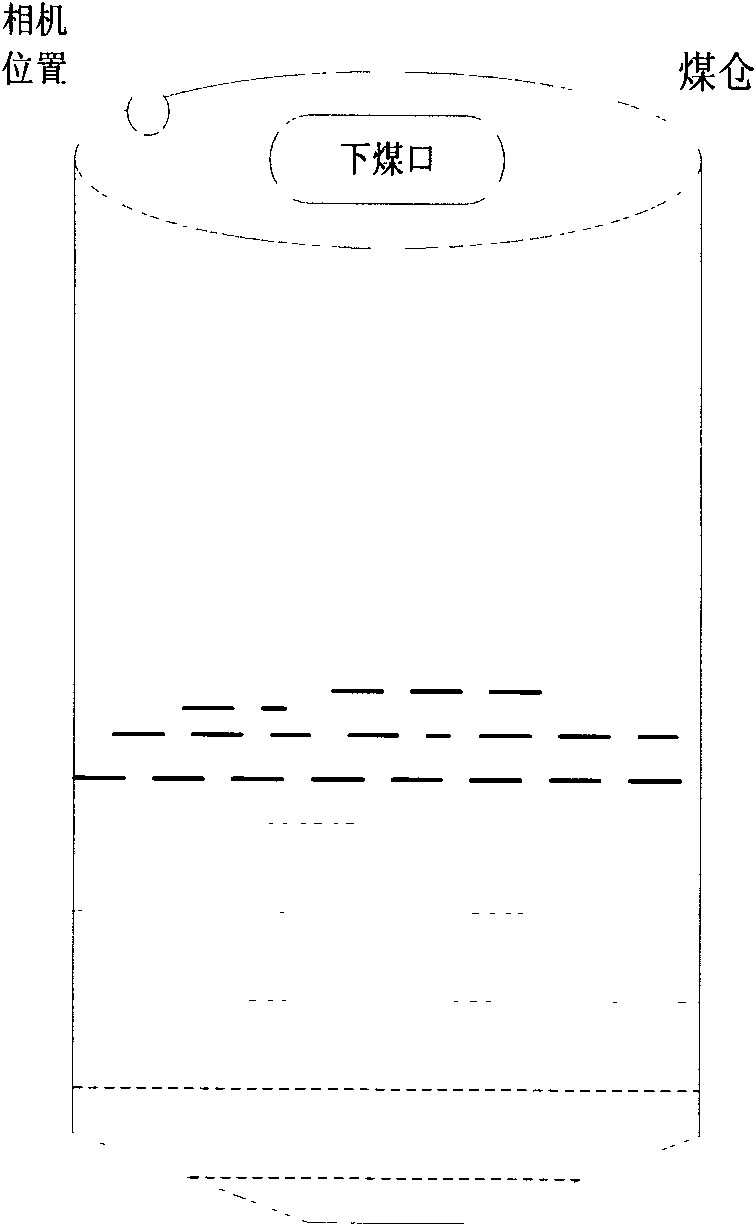

[0069] See attached figure 1 , which describes the installation position of the digital camera system. The digital camera system should be installed on the top of the silo, as close to the silo wall as possible, avoiding the silo discharge port and related facilities to avoid blocking the shooting angle. The digital camera system should include a transparent sealing cover, a dust removal device of the sealing cover and respective fixing devices, and the device should also meet the safety requirements of the application. It should meet the electrical explosion-proof requirements of underground coal mines.

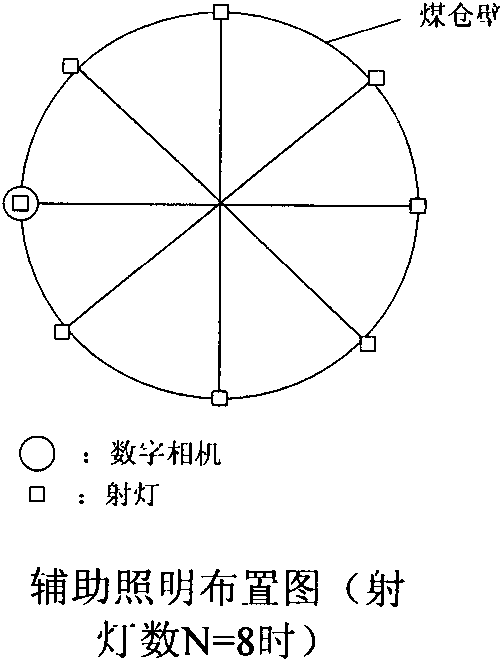

[0070] See attached figure 2 , describes the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com