Optic fiber power beam combiner and preparation method thereof

A beam combiner and power technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of poor output beam quality, unsuitable for high-power fiber lasers, and complex structure of fiber laser coherent synthesis, achieving high coupling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

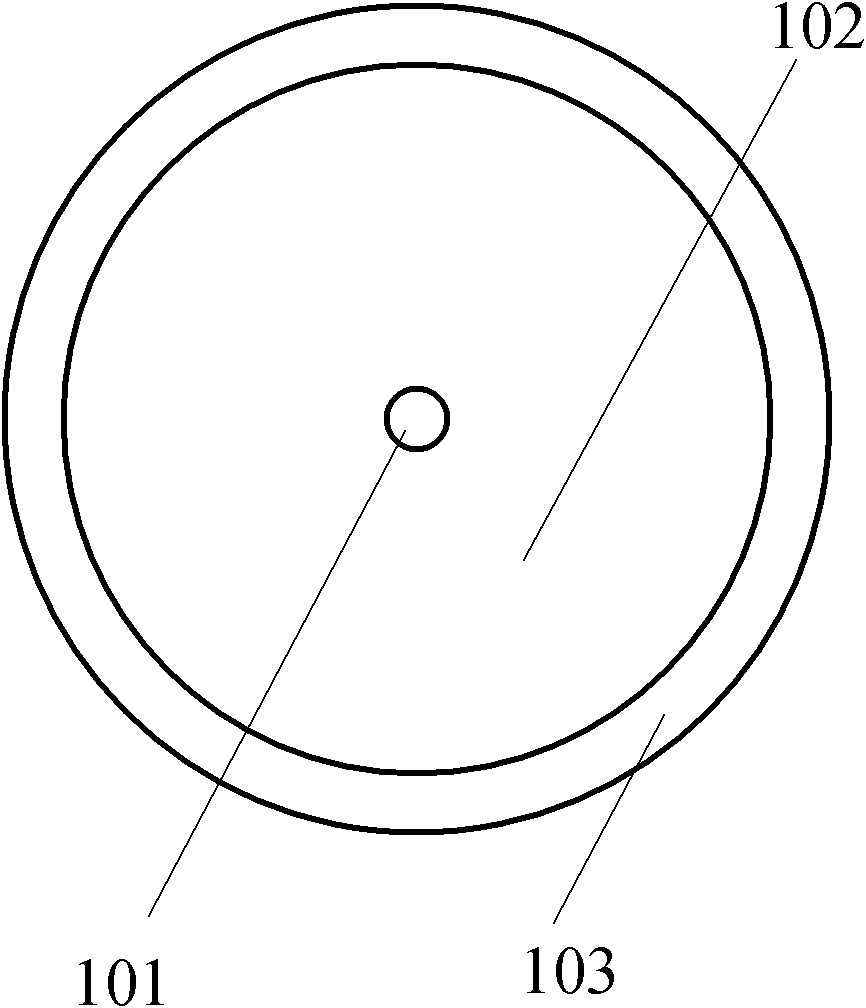

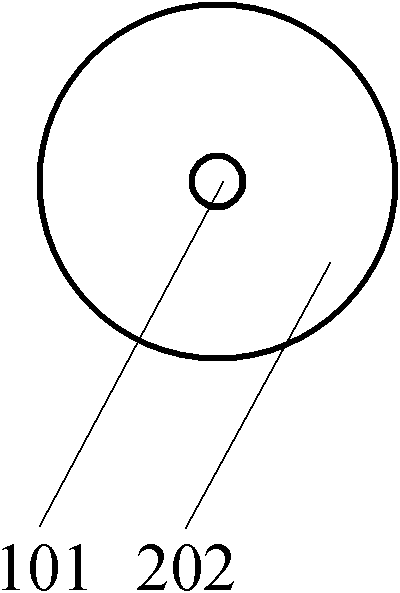

[0026] (1) will figure 1 The outer cladding 103 of the double-clad optical fiber shown is etched away, and the inner cladding layer 102 is uniformly etched to half of the original, that is, the inner cladding layer is etched from 105 μm to about 52 μm, and only the core 101 and the inner cladding layer 202 are left in the etched optical fiber. like figure 2 shown;

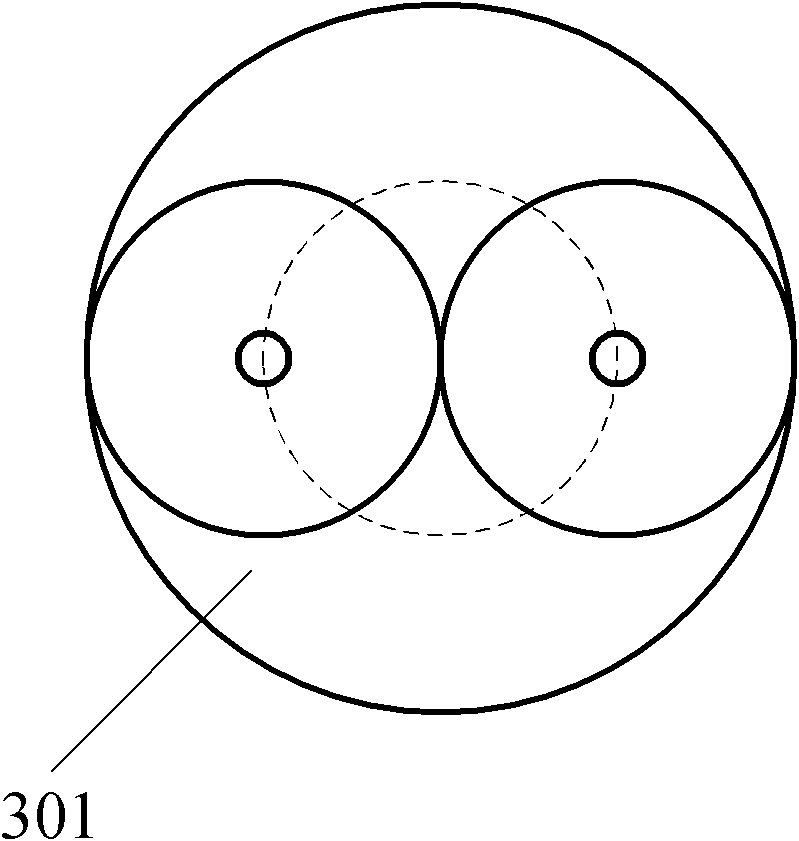

[0027] (2) Closely arrange the three input optical fibers processed in step 1 together, and put the optical fiber bundle into a quartz capillary glass tube 301, such as Figure 4 shown;

[0028] (3) uniformly heat the outside of the quartz capillary glass tube, the heating temperature is 1700 ° C, and the time is 5 minutes, so that it collapses on the optical fiber bundle;

[0029] (4) The treated end of the optical fiber bundle is melted and tapered uniformly. After the drawing is completed, the minimum diameters of the core and cladding in the taper region are 3 μm and 17 μm respectively, and then the coating...

Embodiment 2

[0033] (1) will figure 1 The outer cladding 103 of the double-clad optical fiber shown is etched away, and the cross-section of the inner cladding 102 is polished into a 120° sector, as shown in Figure 7 shown;

[0034] (2) Closely arrange the three input optical fibers processed in step 1 together, and put the optical fiber bundle into a quartz capillary glass tube 301, such as Figure 7 shown;

[0035] (3) uniformly heat the outside of the quartz capillary glass 301 tube, the heating temperature is 1700 ° C, and the time is 5 minutes, so that it collapses on the fiber bundle;

[0036] (4) The treated end of the fiber bundle is melted and tapered uniformly. After the drawing is completed, the minimum diameters of the core and cladding in the taper region are 3 μm and 35 μm respectively (sector quartz rod), and then coated;

[0037] (5) Cut the tapered end flat and spliced with a large-core double-clad fiber 901. The core and inner cladding dimensions are 40 μm and 400 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com