Impactor

A technology of impactor and support seat, applied in the field of impactor, can solve the problems of inability to meet the noise monitoring system, unable to generate acoustic noise signals, small impact energy adjustment range, etc., achieving convenient and fast operation, light weight, and accurate positioning of impact energy. adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The content of the present invention will be further described below in conjunction with the accompanying drawings.

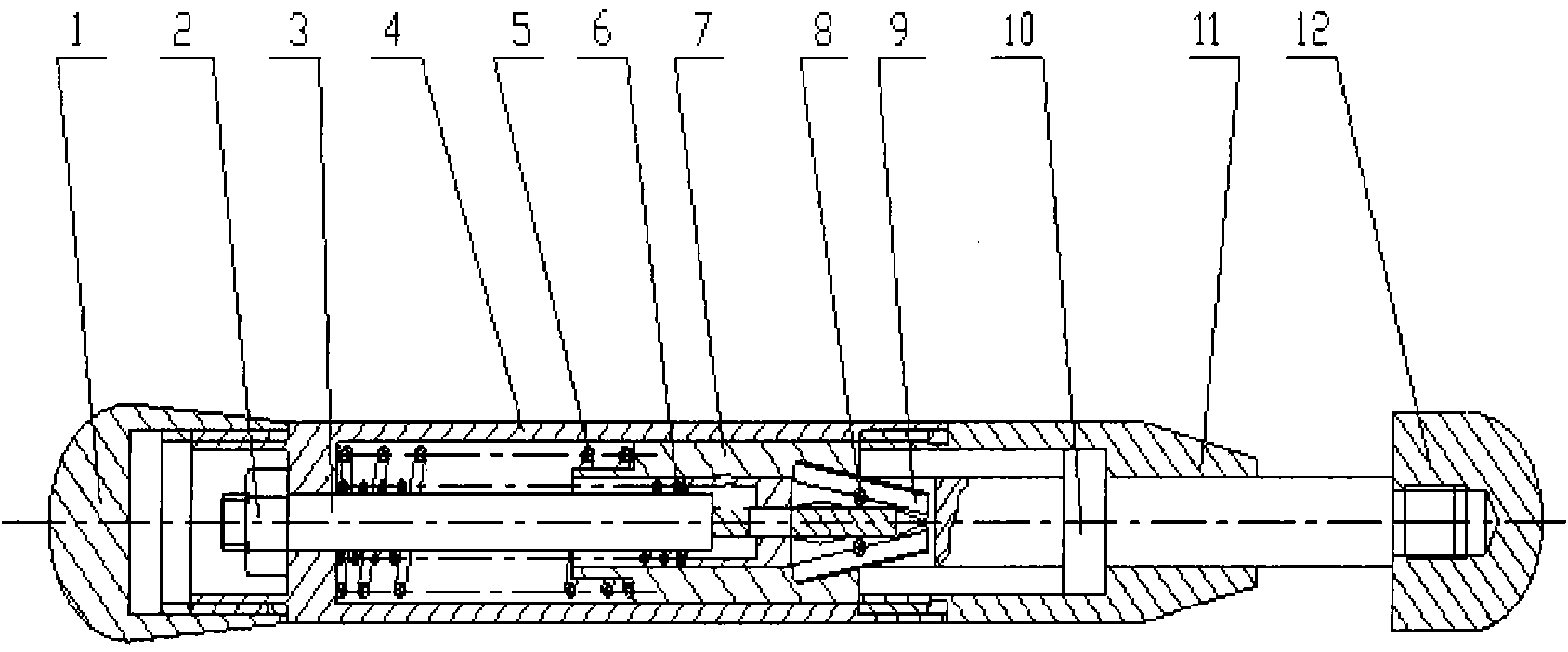

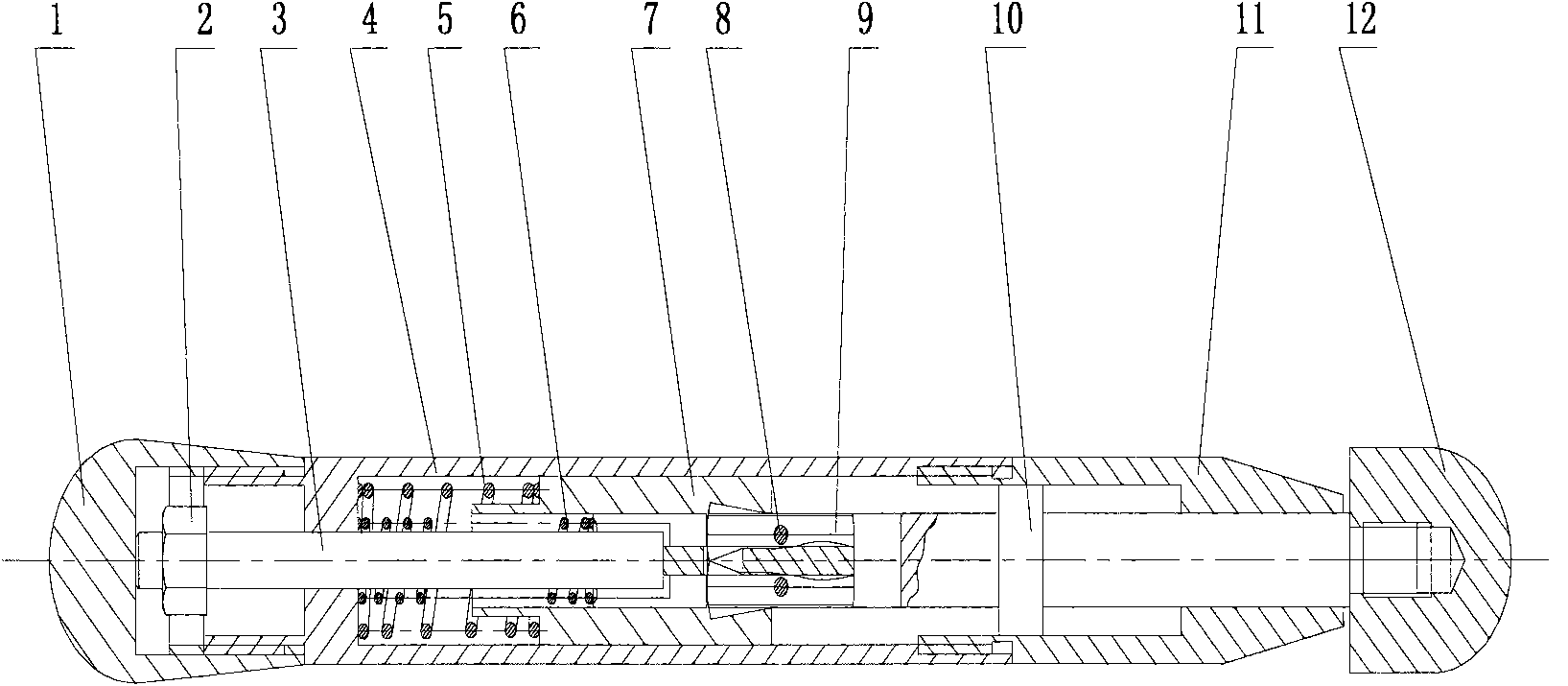

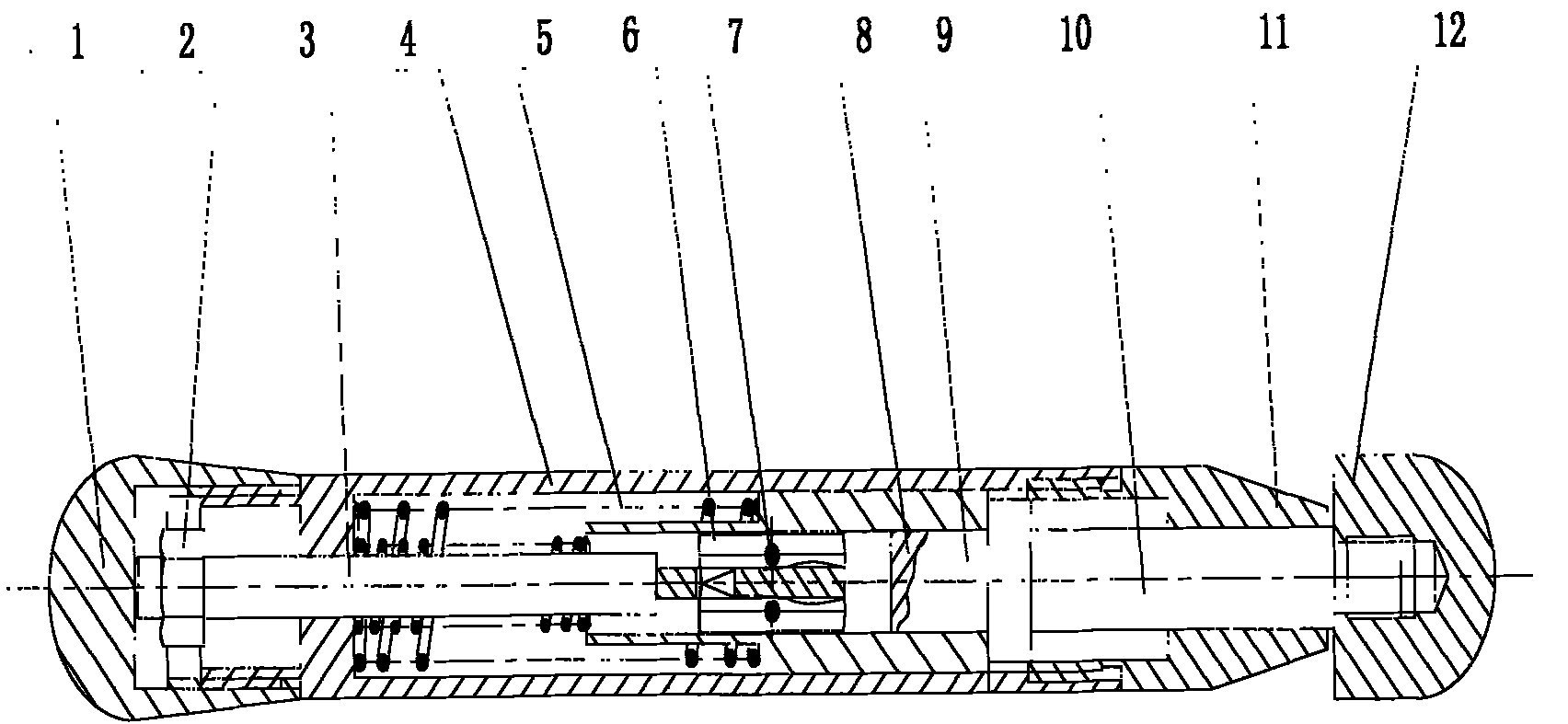

[0012] Such as figure 1 , 2 . As shown in 3, an impactor includes: handle plug 1, nut 2, control rod 3, handle 4, barrel spring 5, return spring 6, barrel 7, rotating shaft 8, rotating support block 9, support seat 10. Lower end head 11 and contact head 12.

[0013] The handle 4 is a cylindrical structure, and has an axial through hole at the bottom, and its upper and lower ends are respectively provided with external threads and internal threads. The control rod 3 is composed of a thick rod at the upper end and a thin rod at the lower end, and has a radially rectangular through hole on the thin rod at the lower end. The thick rod at the upper end of the control rod 3 is inserted into the bottom of the handle 4 to have an axial through hole, and a nut 2 is installed on the upper end of the control rod 3, and the barrel spring 5 with a large diameter a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com