Wet process method for improving chamfer smoothness on top of shallow trench isolation

A shallow trench and smoothness technology, applied in the field of wet process for improving the smoothness of the top chamfer of shallow trench isolation, can solve problems such as reducing the reliability of the device, improve the smoothness, increase the smoothness, and avoid the use of the device. The effect of reliability being affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

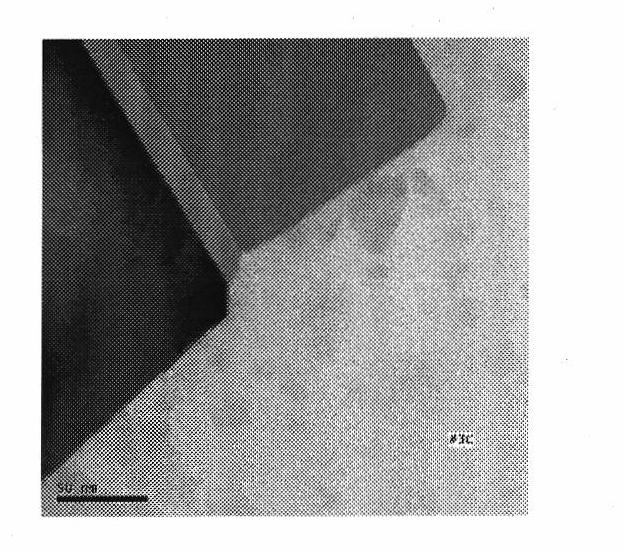

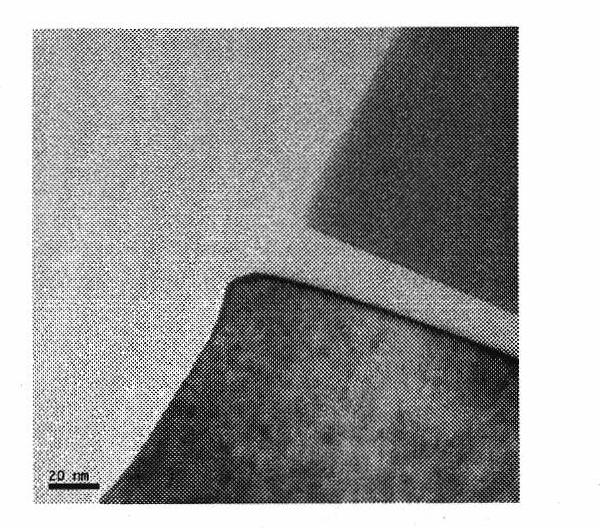

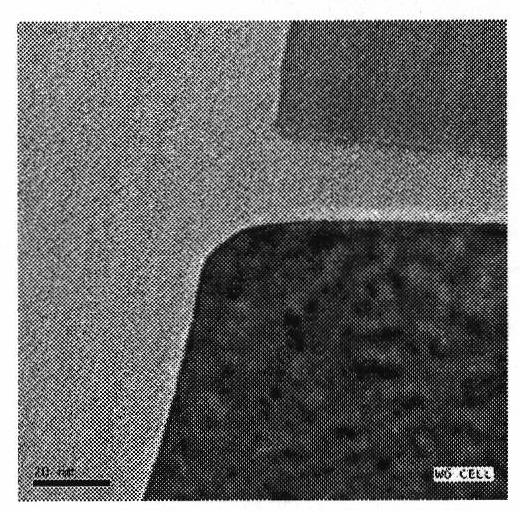

[0016] The method of the invention is mainly suitable for improving the smoothness of top chamfering in STI (Shallow Trench Isolation) modules. In order to improve this structure, a short-term wet APM (ammonia hydrogen peroxide mixture) liquid treatment is added after the nitride film is etched back, and the chamfer shape is adjusted by micro-etching silicon, while avoiding oxidation of the substrate. Overetching of the film. Since the chamfer is etched from the top and the side, it can increase the roundness of the top chamfer of the STI, and avoid affecting the reliability of the device.

[0017] The specific implementation process steps of the inventive method are as follows:

[0018] (1) shallow trench etching and removal of photoresist; as Figure 4A As shown, shallow trench etching can use photoresist 1 as a mask to complete nitride f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com