Ultrathin packaging structure and packaging method of image sensing chip

A technology of image sensing and packaging structure, which is applied in radiation control devices, electrical components, electric solid devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

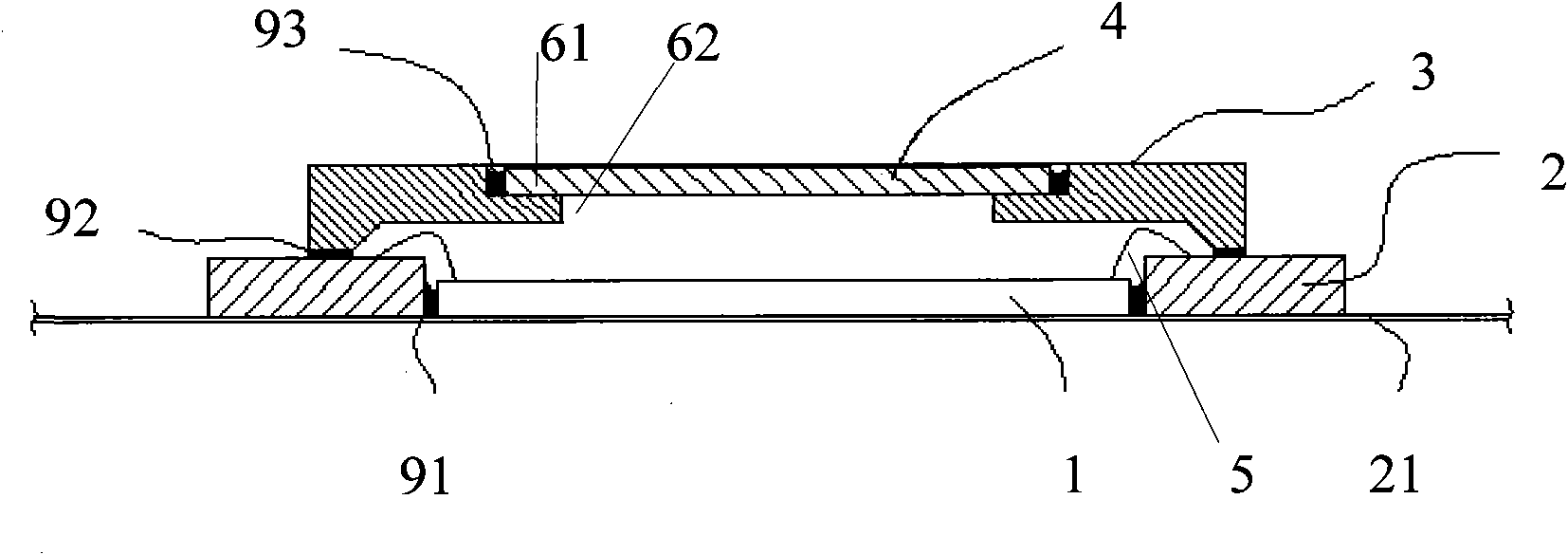

[0041] Such as Figure 1-3 As shown, the packaging process of the ultra-thin packaging structure of the image sensing chip provided by the first preferred embodiment of the present invention includes the following steps:

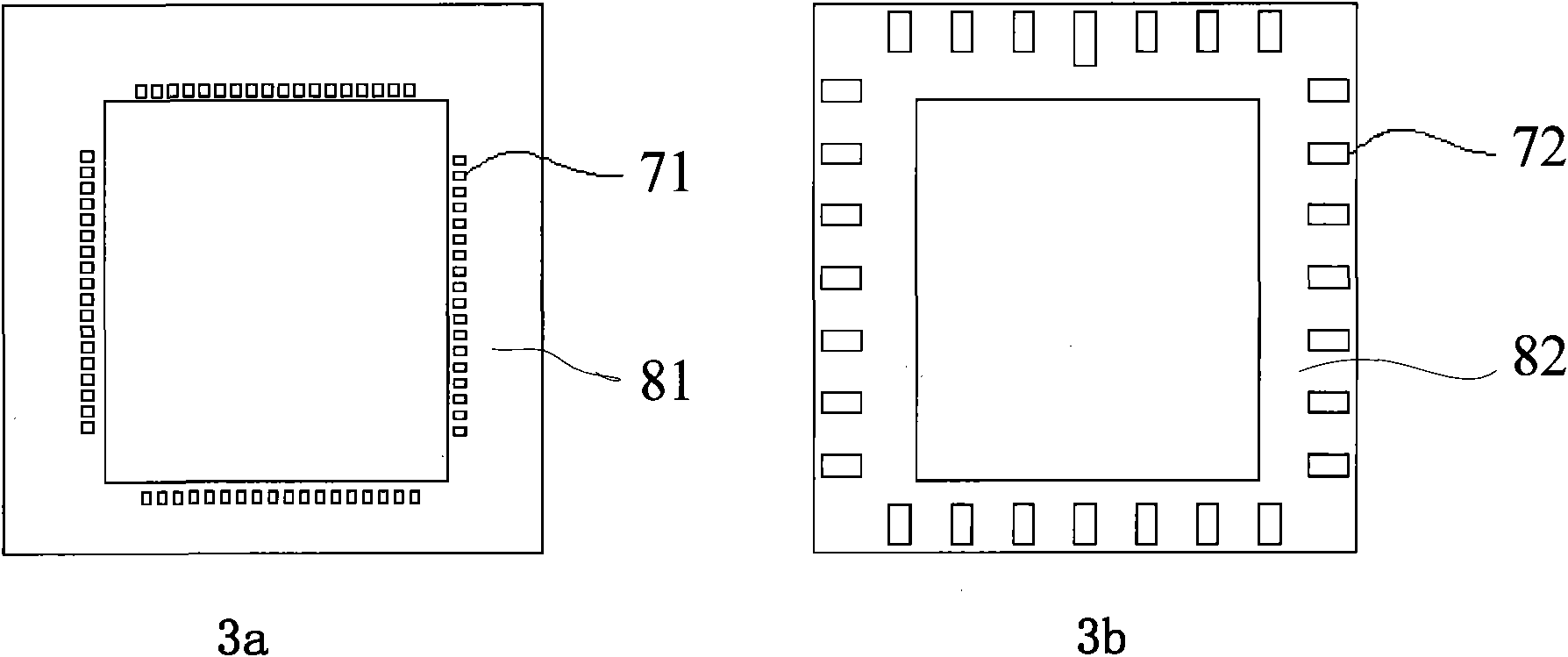

[0042] The first step: stick the film 21 on the lower surface 82 of the substrate 2, and apply glue 91 around the hollow part of the substrate 2;

[0043] Step 2: Put the image sensing chip 1 into the hollowed out part of the substrate 2, cure the glue 91, and fix the substrate 2 and the image sensing chip 1 together.

[0044] Step 3: Connect the pads 71 on the upper surface 81 to the pads on the image sensing chip 1 with wires 5;

[0045] Step 4: Apply glue 92 around the upper surface 81 of the substrate 2, place the bracket 3 on top of the glue 92, then cure the glue 92, and fix the bracket and the substrate together;

[0046] Step 5: Apply glue around the first step 61 of the bracket 3, put the light-transmitting glass 4 on the glue in the first step fo...

Embodiment 2

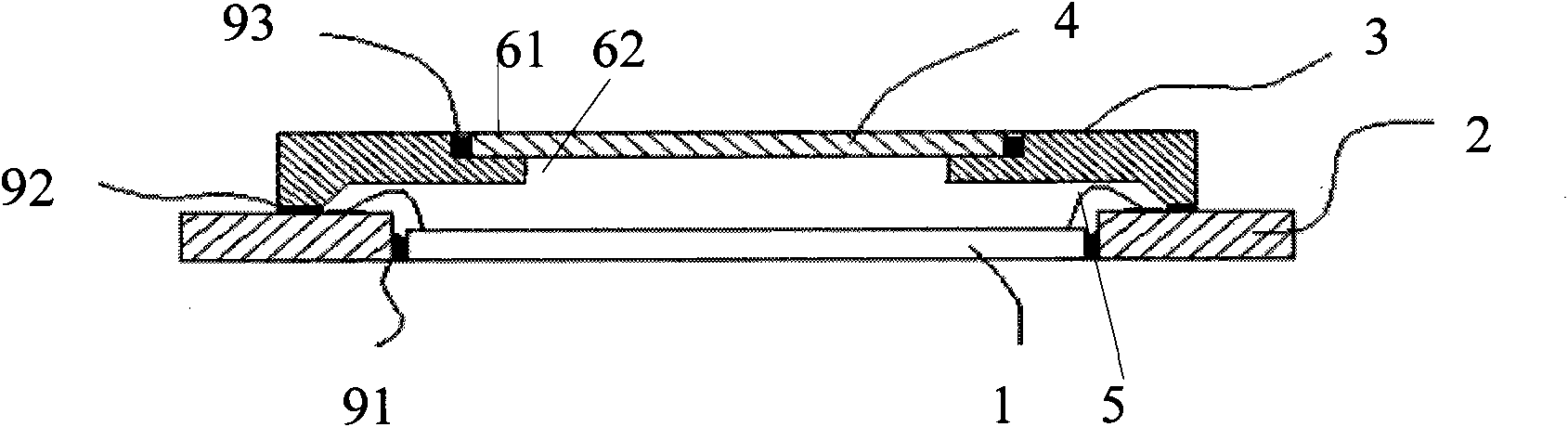

[0049] Such as Figure 3-4 As shown, the packaging process of the ultra-thin packaging structure of the image sensing chip provided by the second preferred embodiment of the present invention includes the following steps:

[0050] Step 1: stick the film 21 on the lower surface 82 of the substrate 2, and then put the image sensing chip 1 into the hollow part of the substrate 2 and stick it together with the film 21;

[0051] Step 2: Connect the pads 71 on the upper surface 81 to the pads on the image sensing chip 1 with wires 5;

[0052] Step 3: Use glue 94 to apply glue around the hollowed-out part of the substrate 2, including the connection between the image sensor chip 1 and the substrate 2 and the connection between the support 3 and the upper surface 81 of the substrate. Put it on the glue on the upper surface 81 of the substrate, then cure the glue, and fix the substrate 2, the image sensing chip 1 and the bracket 3 together;

[0053] Step 4: Apply glue around the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com