Surface labeling type polymer PTC senistor and manufacturing method thereof

A thermistor, surface mount technology, used in current-responsive resistors, resistors with positive temperature coefficients, etc. The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

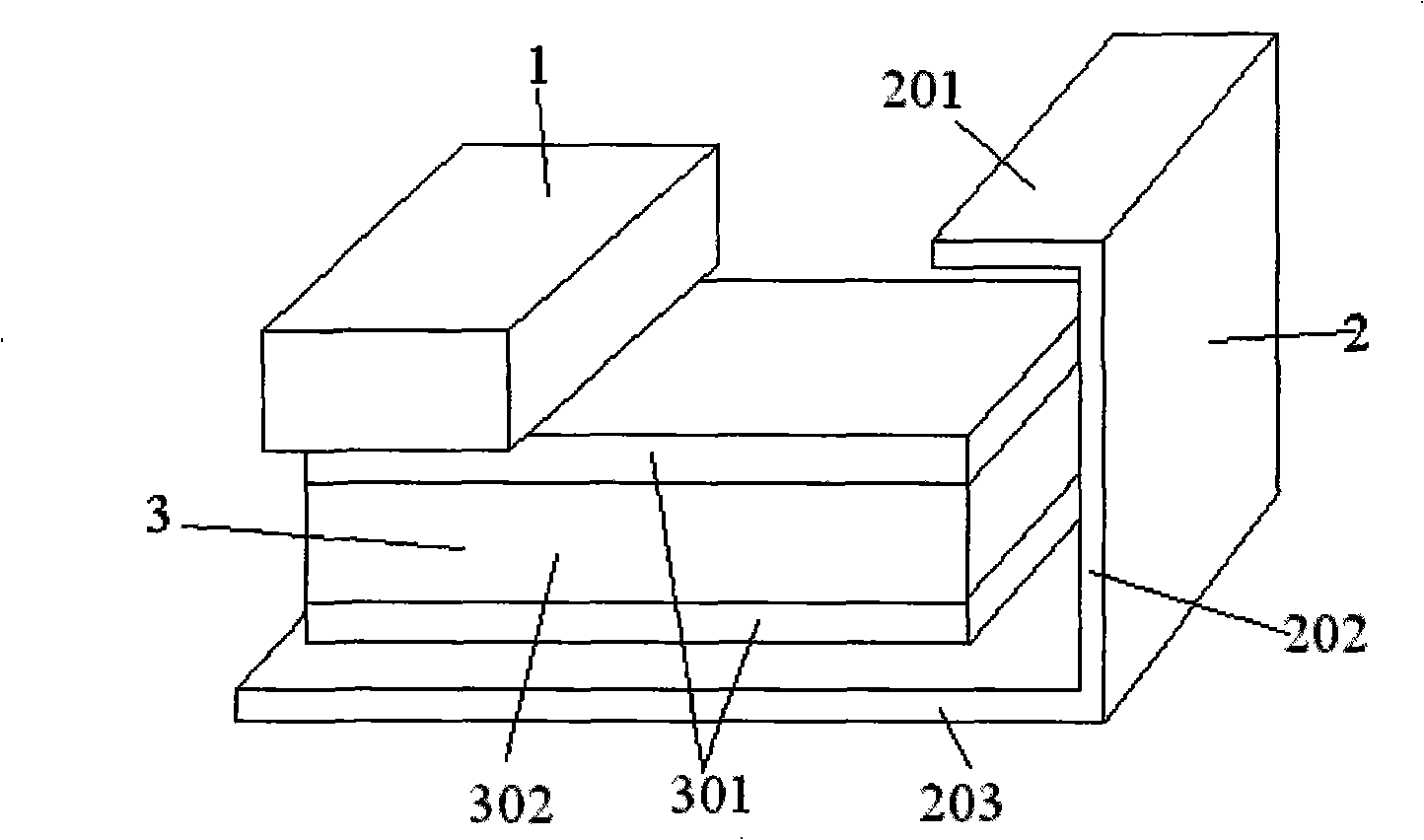

[0027] Press the polymer PTC material into a sheet with a thickness of 0.45mm, and then use a flat vulcanizer to coat copper foil with a thickness of 0.035mm on both sides, and hot press to form a composite sheet with a total thickness of 0.52mm, that is, the polymer PTC chip 3. After electron accelerator radiation cross-linking, use a punch to punch into 3.0*3.8mm rectangular pieces, wash and dry them for later use.

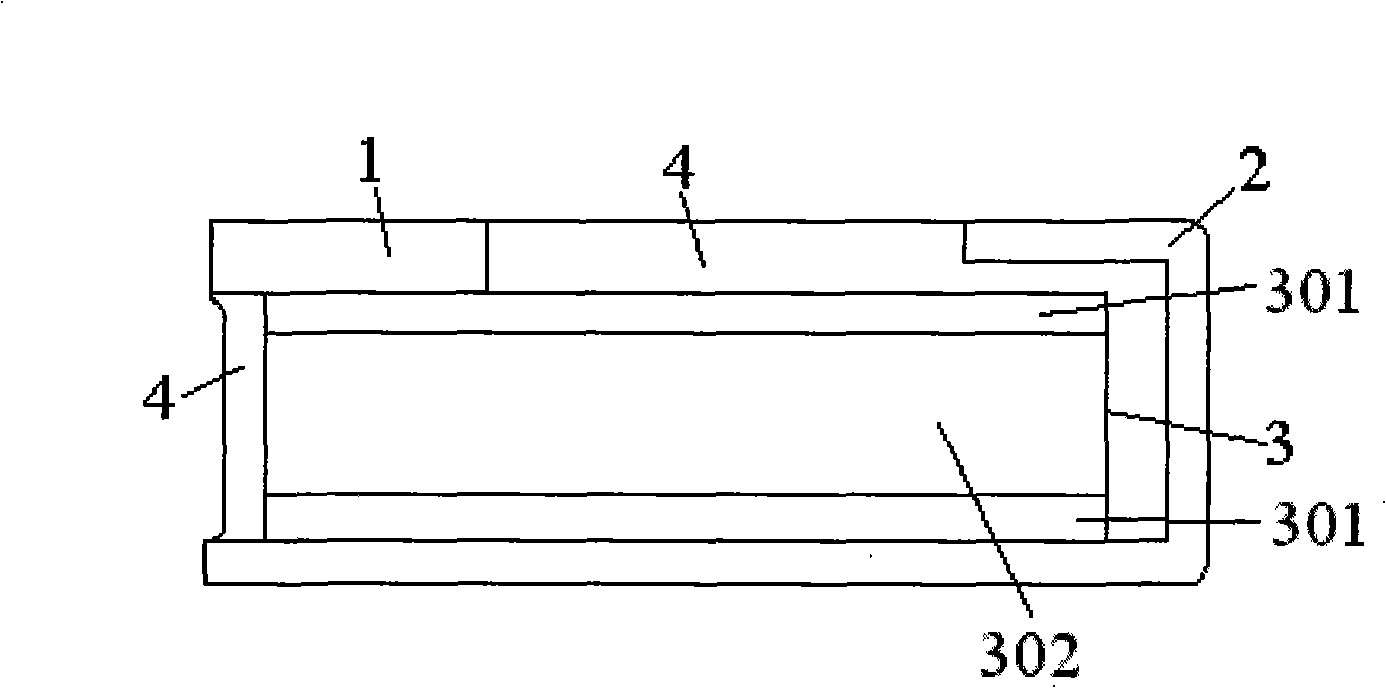

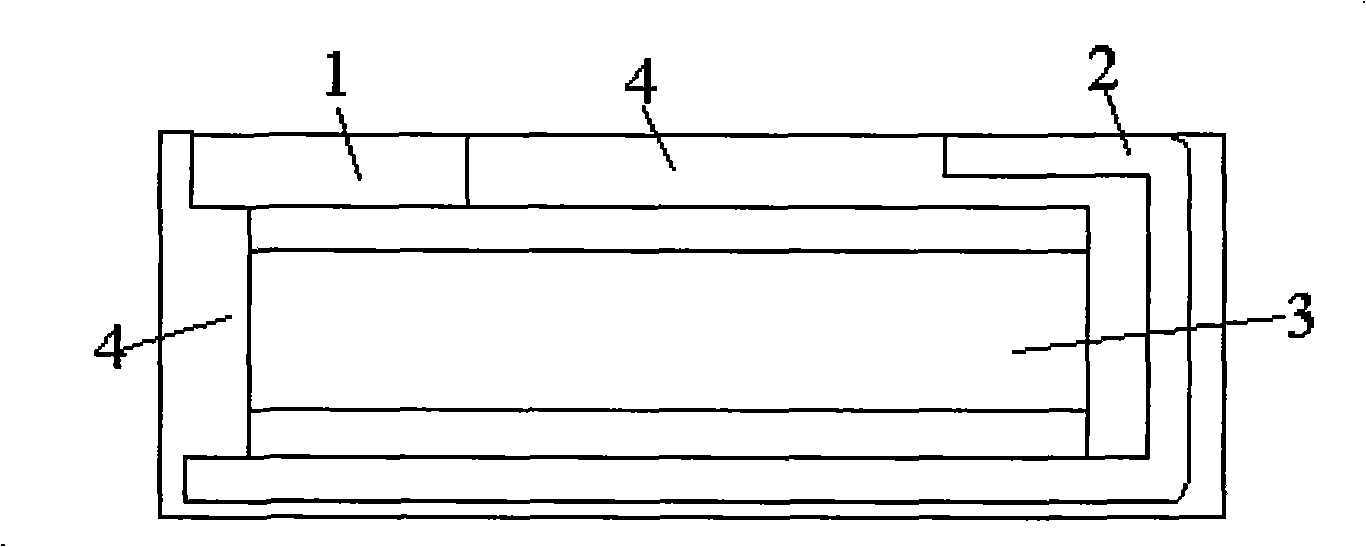

[0028] Utilize the reflow soldering process to weld the lead-out electrodes on the upper and lower surfaces of the polymer PTC chip 3 ( image 3 shown). Then apply epoxy resin ( figure 1 shown), heating and curing. That is, a surface mount type polymer PTC thermistor is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com