Template and method of making high aspect ratio template for lithography and use of the template for perforating a substrate at nanoscale

A technology of aspect ratio and template, which is applied in the field of perforation of nano-scale substrates, can solve the problems of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

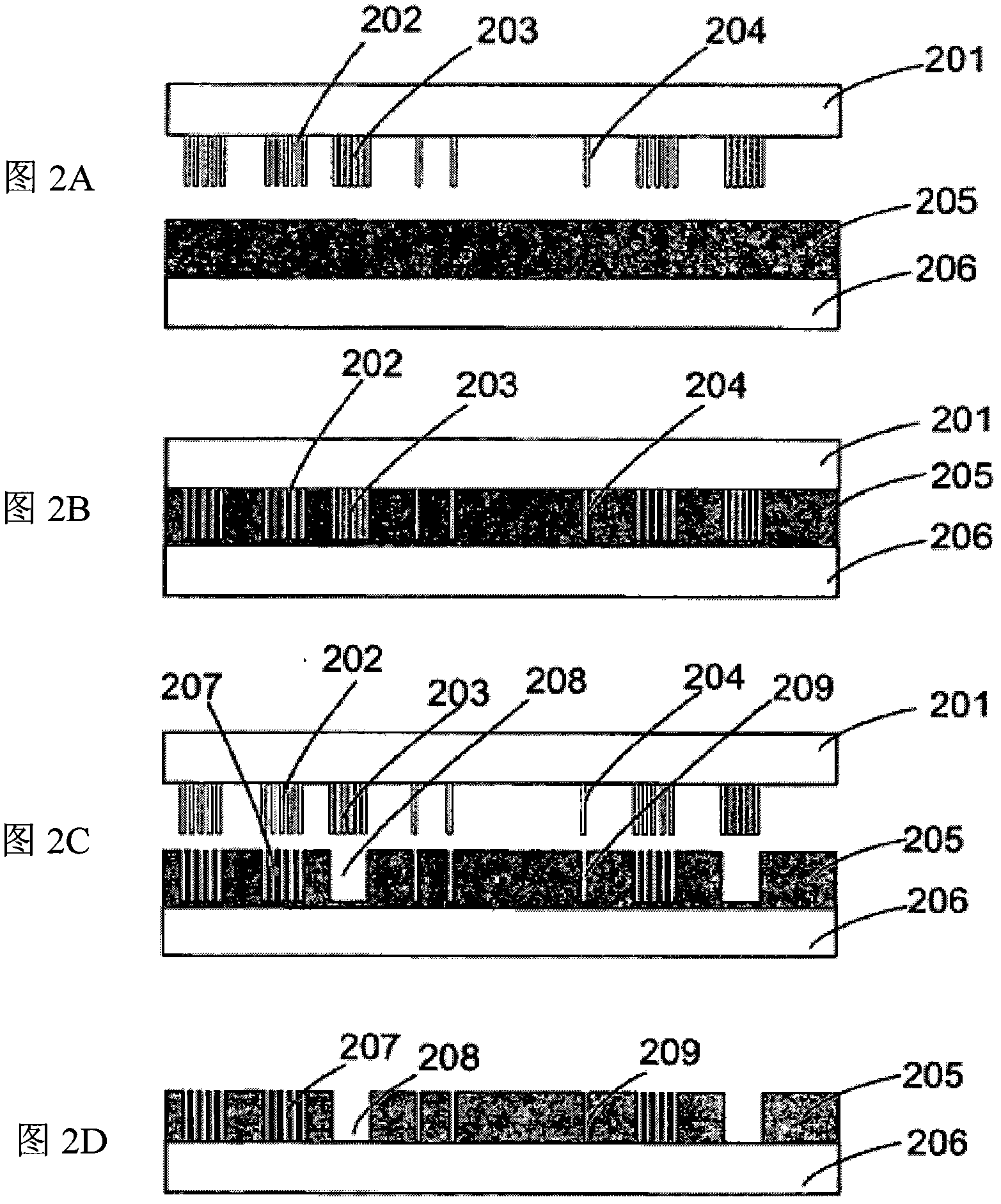

[0038] According to the template 201 of the present invention such as figure 2 As shown in A. Nanostructures 204 with independent vertical alignment. Also visible on the stamp is an array 202 of vertically aligned nanostructures and a cluster of grown nanostructures 203 . A polymer / barrier 205 is deposited on the underlying substrate / wafer 206 . The substrate may contain multiple layers.

[0039] figure 2 In B a template 201 according to the invention is pressed against a polymer layer 205 on a wafer 206 . The wafer and barrier are heated above the glass transition temperature of the polymer. After cooling the template is lifted, leaving depressions 207, 208 and 209 in the barrier layer. Depending on the localization of the nanostructures, different types of results can occur in the imprinted polymer layer. for figure 2 Individual fibers 204 and finely spaced array 202 shown in A, each fiber will give depressions 207 and 209 in the polymer. For a very fine pitch array...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com