Small-town sewage pretreatment integrated device and method

A technology for sewage pretreatment and small towns, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of smooth mud, shortened process and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

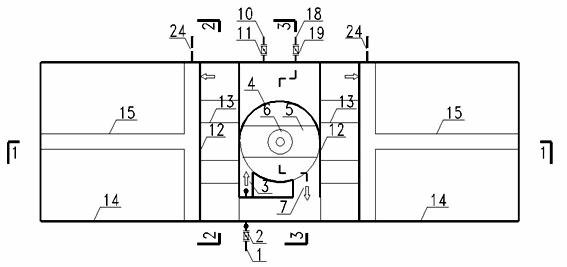

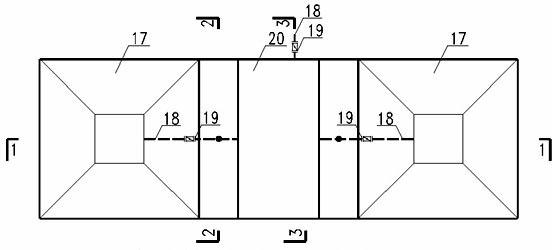

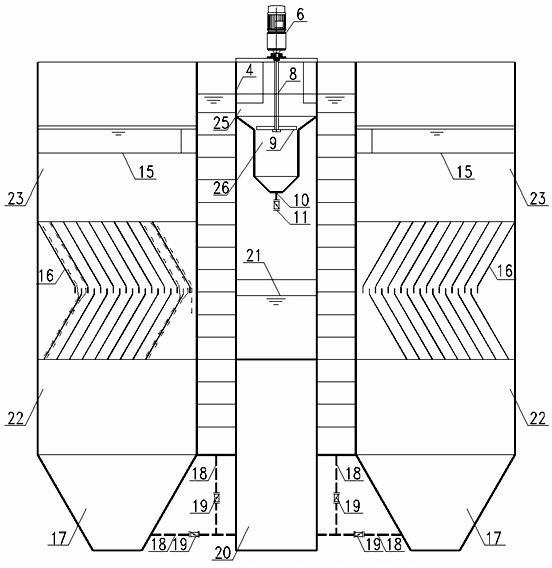

[0029] Refer to attached Figure 1~6 , the equipment is composed of a swirling grit chamber 4, two folded plate flocculation reaction tanks 12, two inclined plate sedimentation tanks 14, a sand storage tank 21, and a mud storage tank with more than 20 kinds of technological structures integrated into one. The swirling grit chamber 4 is located in the middle of the equipment. The folded plate flocculation reaction tank 12 and the inclined plate sedimentation tank 14 are arranged in sequence on both sides of the swirl grit chamber 4. The bottom side of the swirl grit chamber 4 is arranged in sequence from top to bottom for sand storage. Pond 21, storage mud pond 20.

[0030] The swirling flow grit chamber 4 is large at the top and small at the bottom, the upper part is the grit separation area 25, the lower part is the sand collection area 26, and the top is fixed with a working bridge 5 for fixing the agitator, which is composed of a stepless variable speed motor 6 and a transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com