Degassing technology in synthetic process of neoprene

A technology of neoprene and neoprene latex, which is applied in the degassing field, can solve the problems of pipeline blockage, low monomer recovery rate, and low degassing rate, and achieve the effects of reducing consumption, high degassing efficiency, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

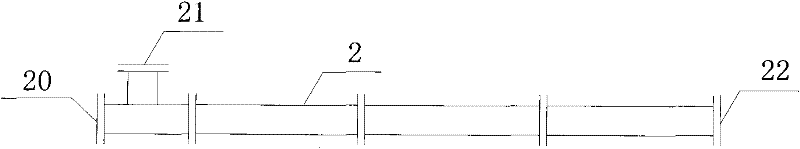

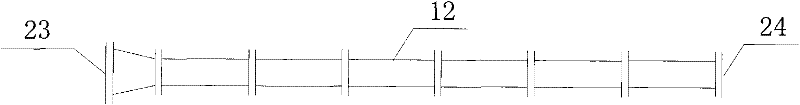

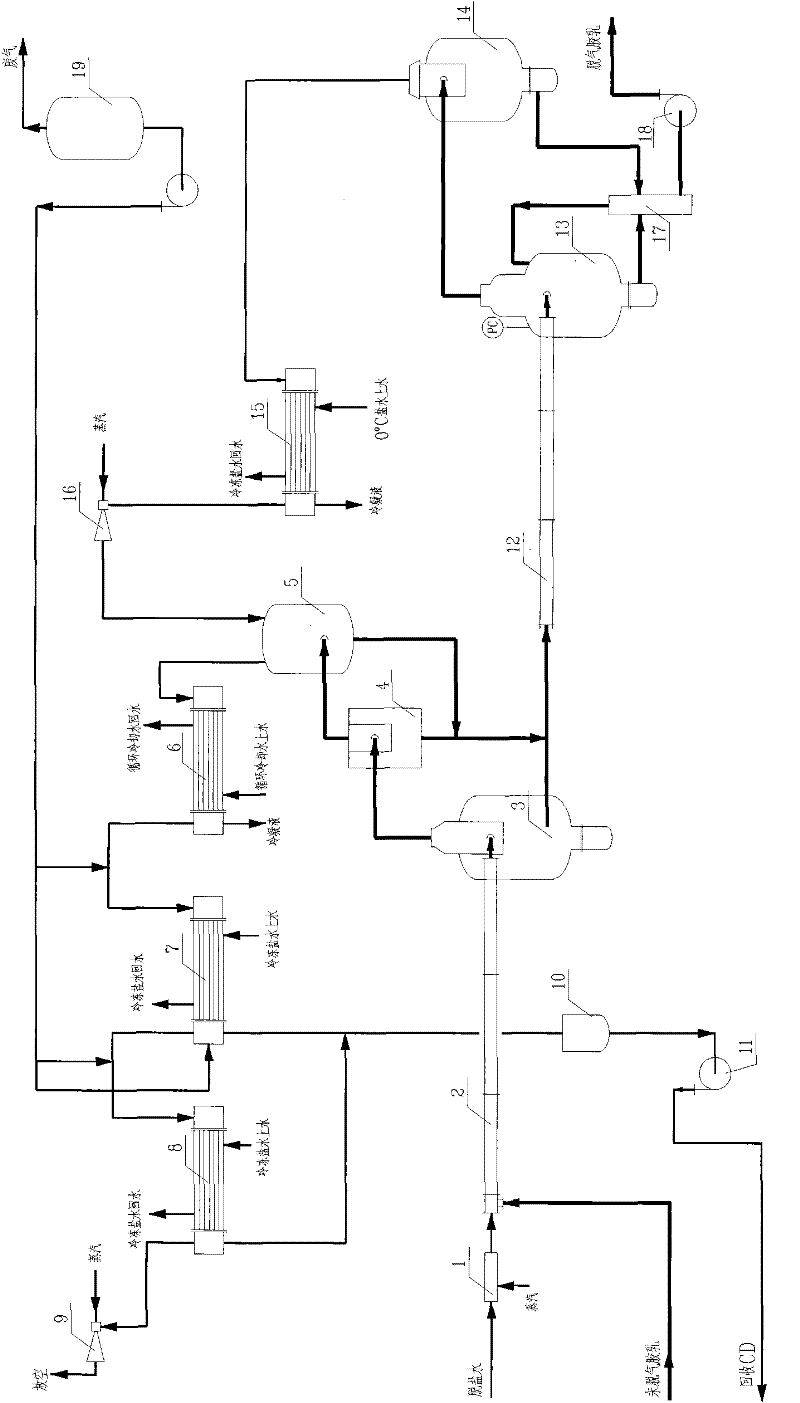

[0031] The primary degassing is carried out under vacuum 220mmHg.

[0032] Firstly, superheated steam (126° C.) is cooled by adding desalted water in the steam desuperheater, and the temperature of the steam is controlled at 102° C., and enters the primary degassing pipe 2 from the steam inlet 20 . Undegassed latex (22°C) at 9.5m 3 The flow rate of / h enters the primary degassing pipe 2 from the non-degassed latex inlet 21. The degassed latex and steam are directly mixed in the primary degassing pipe 2 for steam stripping. The mixing ratio of steam and latex is 0.31:1 (wt). The primary degassing pipe 2 consists of three sections with an inner diameter of 100mm and a length of 10500mm. The undegassed latex is mixed with steam in the primary degassing pipe 2, diluted and heated to 58°C, the unreacted CD in the latex is vaporized, and the CD-containing latex foam enters the primary separator 3 from the tangential direction, and the emulsion is separated along the primary stage ...

Embodiment 2

[0038] The primary degassing is carried out under vacuum 200mmHg.

[0039] First, superheated steam (128°C) is cooled by adding desalted water in the steam desuperheater, the steam temperature is controlled at 105°C, and enters the primary degassing pipe 2 from the steam inlet 20 . Undegassed latex (23°C) at 7.5m 3 The flow rate of / h enters the primary degassing pipe 2 from the non-degassed latex inlet 21. The degassed latex and steam are directly mixed in the primary degassing pipe 2 for steam stripping. The mixing ratio of steam and latex is 0.25:1 (wt). The primary degassing pipe 2 consists of three sections with an inner diameter of 100mm and a length of 11000mm. The undegassed latex is mixed with steam in the primary degassing pipe 2, diluted and heated to 62°C, the unreacted CD in the latex is vaporized, and the CD-containing latex foam enters the primary separator 3 from the tangential direction, and the emulsion is separated along the primary stage The inner wall of...

Embodiment 3

[0045] The primary degassing is carried out under vacuum 180mmHg.

[0046] Firstly, superheated steam (132° C.) is cooled by adding desalted water in the steam desuperheater, and the temperature of the steam is controlled at 108° C., and enters the primary degassing pipe 2 from the steam inlet 20 . Undegassed latex (25°C) at 5.5m 3 The flow rate of / h enters the primary degassing pipe 2 from the non-degassed latex inlet 21. The degassed latex and steam are directly mixed in the primary degassing pipe 2 for steam stripping. The mixing ratio of steam and latex is 0.18:1 (wt). The primary degassing pipe 2 consists of three sections with an inner diameter of 100mm and a length of 11500mm. The undegassed latex is mixed with steam in the primary degassing pipe 2, diluted and heated to 64°C, the unreacted CD in the latex is vaporized, and the CD-containing latex foam enters the primary separator 3 from the tangential direction, and the emulsion is separated along the primary stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com