Composite preparation method for fine crystal titanium alloy

A titanium alloy and fine-grain technology, which is applied in the field of composite preparation of fine-grained titanium alloys, can solve the problems of large machining allowance, high cost, low material utilization rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

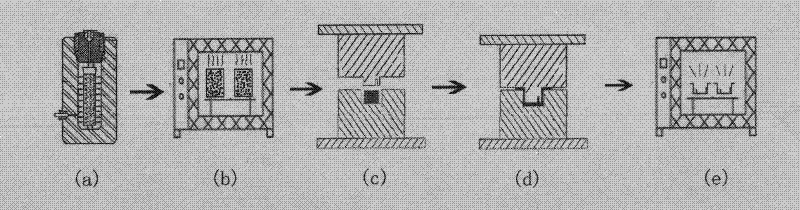

Method used

Image

Examples

example 1

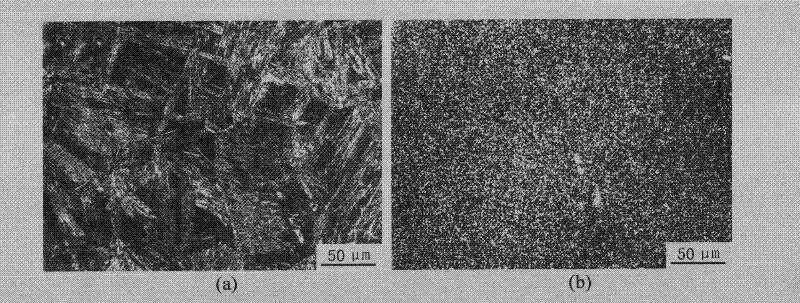

[0029] Ti-1023 powdered titanium alloy ( figure 2 ).

[0030] After the Ti-1023 alloy powder is prepared by the hydrogenation dehydrogenation process in the preparation of the blank in step 1 of the method, the -150 mesh powder is screened out for packaging, and the initial blank is obtained by cold isostatic pressing under a pressure of 200 MPa. The cold isostatic pressing time is 10min; After step 2 vacuum sintering, the vacuum degree is 10 -3 Pa, the sintering temperature is 1300°C, and the sintering holding time is 3h, the structure of the sintered Ti-1023 powder alloy is as follows figure 2 As shown in (a); after step 3 high-temperature isothermal forging, the isothermal forging temperature is 840 °C, and the constant strain rate is controlled to 5×10 -2 the s -1 , the total deformation of forging is 60%; after continuous low-temperature isothermal forging in step 4, the temperature of isothermal forging is 760°C, and the constant strain rate is controlled as 5×10 -...

example 2

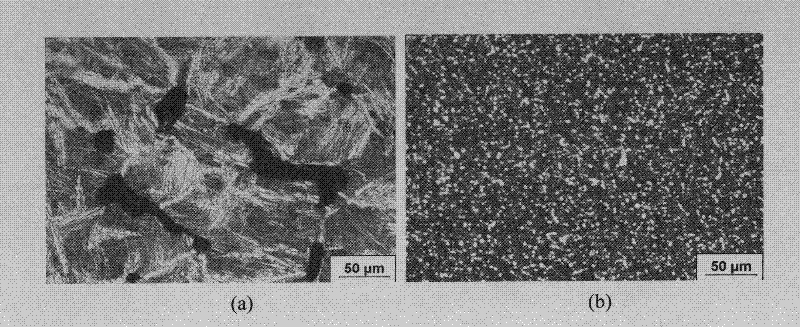

[0034] Ti-17 powdered titanium alloy ( image 3 ).

[0035] After the Ti-17 alloy powder is prepared by the hydrogenation dehydrogenation process in the preparation of the blank in step 1 of this method, the 100-150 mesh powder is screened out for packaging, and the initial blank is obtained by cold isostatic pressing under a pressure of 200 MPa. The cold isostatic pressing time 15min; through step 2 vacuum sintering, the vacuum degree is 10 -3 Pa, the sintering temperature is 1350°C, and the sintering holding time is 3h. The structure of the sintered Ti-17 powder alloy is as follows image 3 As shown in (a); after step 3 high-temperature isothermal forging, the isothermal forging temperature is 920 °C, and the constant strain rate is controlled to 5×10 -2 the s -1 , the total deformation of forging is 70%; continuous low-temperature isothermal forging in step 4, the temperature of isothermal forging is 860°C, and the constant strain rate is controlled as 5×10 -2 the s -1 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com