Performance test device for micro heat exchanger

A technology of testing devices and heat exchangers, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., and can solve problems such as large data errors and meaninglessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

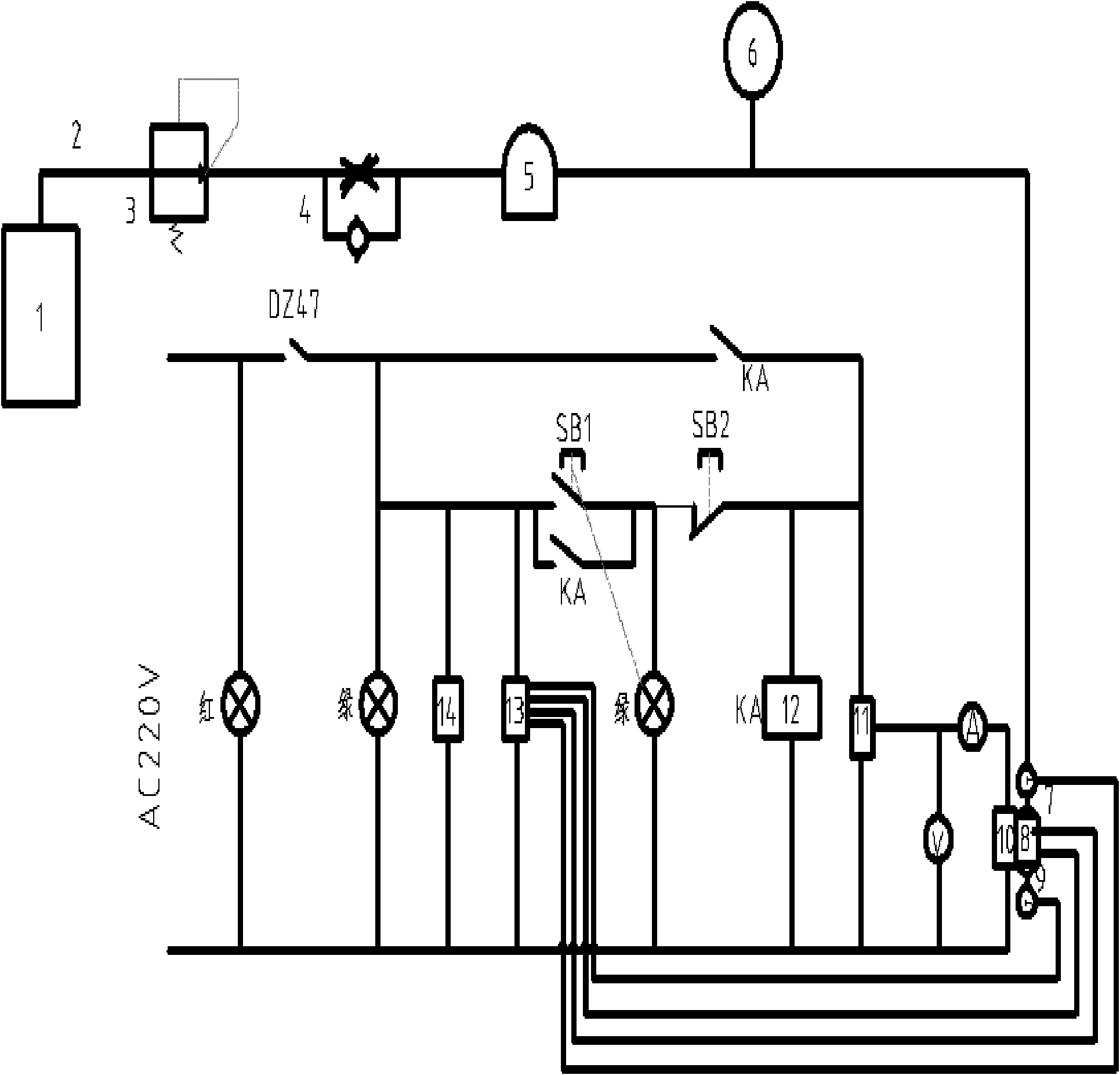

[0022] Such as figure 1 As shown, the present invention includes two loops, that is, the experimental working fluid loop and the electrical control unit. The experimental principle is as follows: Nitrogen (N 2 ) enters the flow meter 5 through the gas source inlet pipe 2, the pressure reducing valve 3 and the one-way throttle valve 4, flows out from the precision flow meter, enters the air inlet section 7 equipped with the precision pressure gauge 6, and enters the micro heat exchanger 8, directly enter the atmosphere after flowing out from the air outlet section 9. The functions of each component are: the precision flowmeter 5 can measure the gas volume flow rate entering the micro heat exchanger, the precision pressure gauge can measure the pressure level before the gas enters the micro heat exchanger, and the pressure drop of the measured micro heat exchanger 8 is It is the indication value of gauge pressure of precision pressure gauge 6. In the electrical control unit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com