Flexible hollow cable

A hollow cable, flexible technology, used in power cables, multi-core cable end components, cables, etc., can solve problems such as increasing resistivity and failure rate, shortening cable service life, and limiting the length of cable spools. The number of intermediate joints, ensuring normal service life and good heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

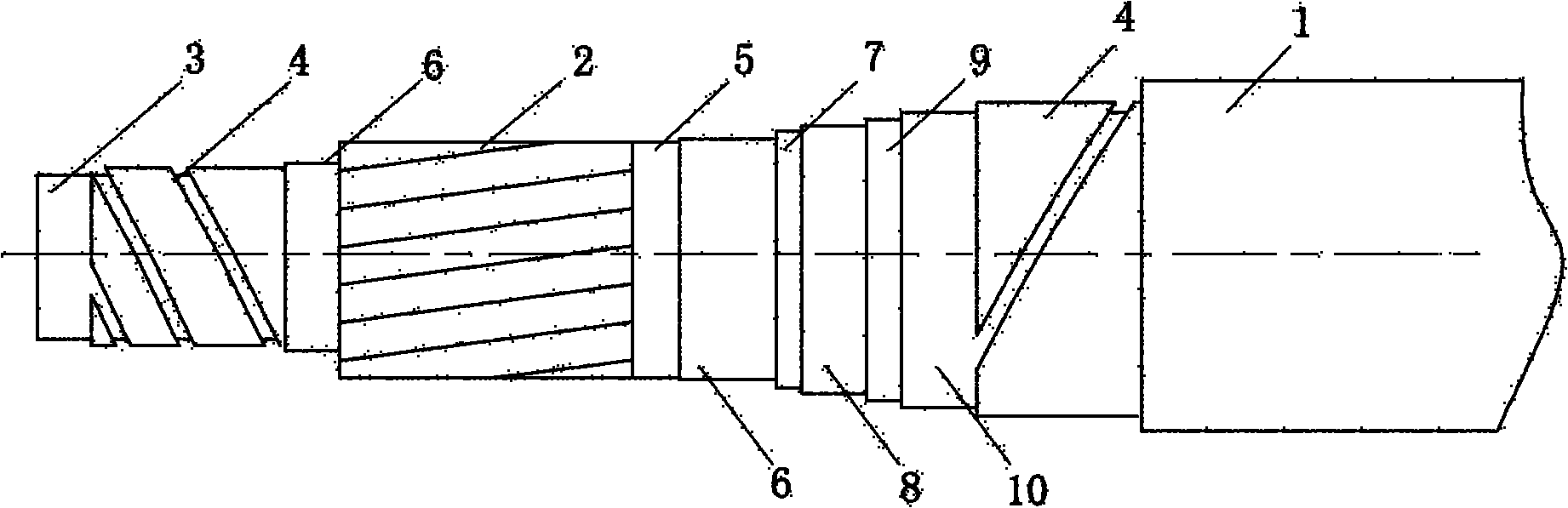

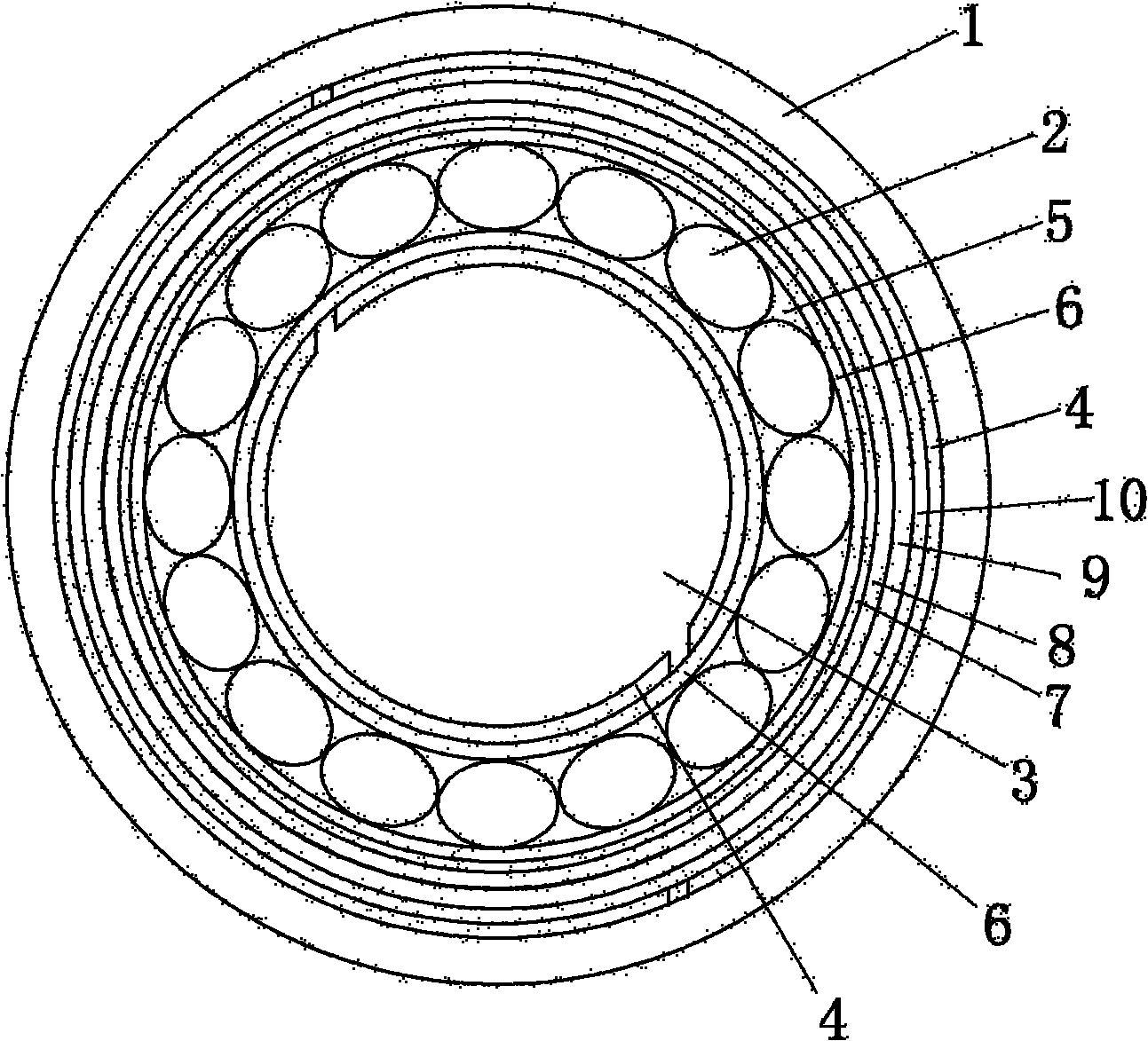

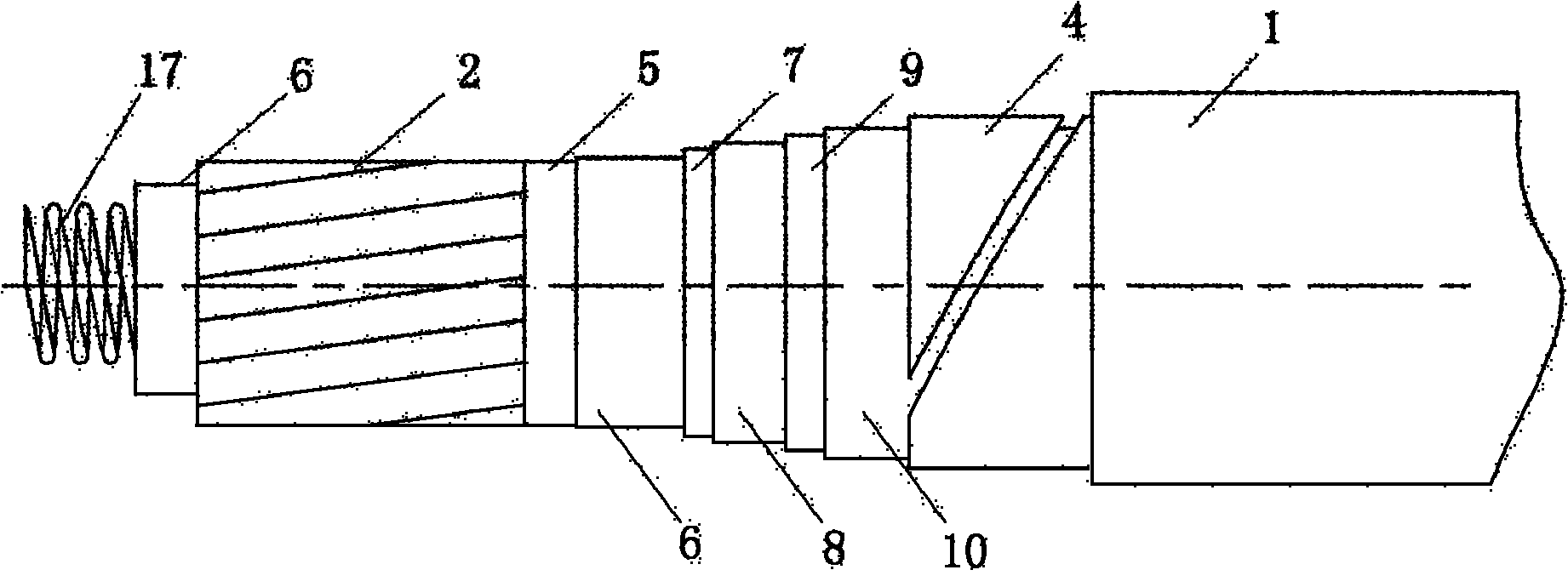

[0034] As shown in Figures 1 and 2, the cable in this embodiment includes multiple wires 2 (mostly copper or aluminum) and an insulating outer sheath 1 covering all wires. The wires 2 are arranged in a hollow arrangement, and the wires are twisted. Weave tight contact, such as twisting the opposite direction of the multi-layer conductor barrier to prevent the adult cable from twisting. The central hollow layer formed after the wires are arranged is filled with a lightweight elastic filler 3. In order to support the lateral pressure of the cable, a steel armor layer 4 is wound around the lightweight elastic material. The steel armor layer is the supporting armor body, which is made of spiral steel armor or metal corrugated pipe (metal corrugated pipe is similar to the shower head and Metal hose of water pipe), a cross-linked polyethylene insulation layer 6 is provided between the steel armor layer 4 and the wire. The multi-strand wire is also provided with a shielding layer 5 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com