Continuous production device of hydroponics pasture

A production device and pasture technology, applied in the field of agricultural engineering, can solve problems such as shortage and shortage of forage, and achieve the effects of meeting production needs, less water consumption, and increasing output per unit area and annual output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

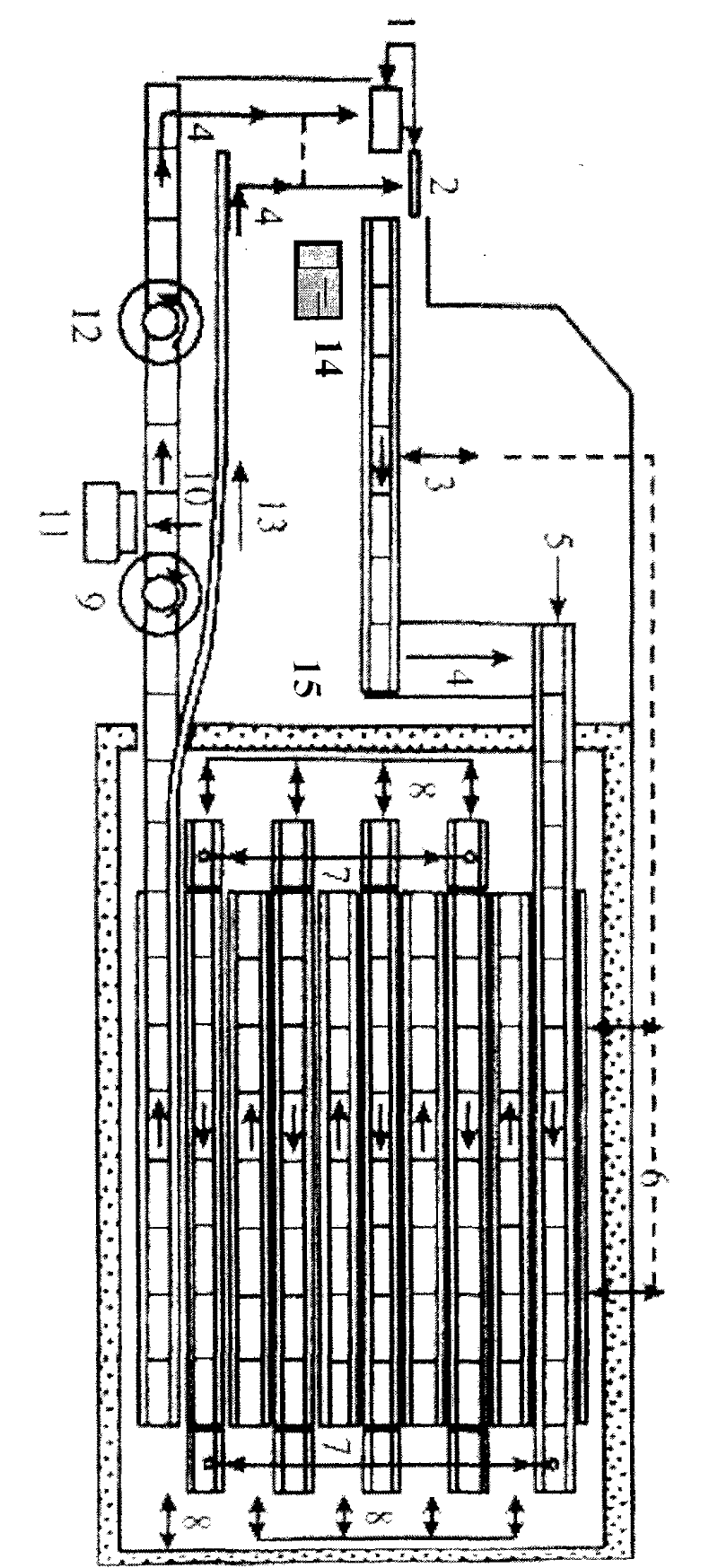

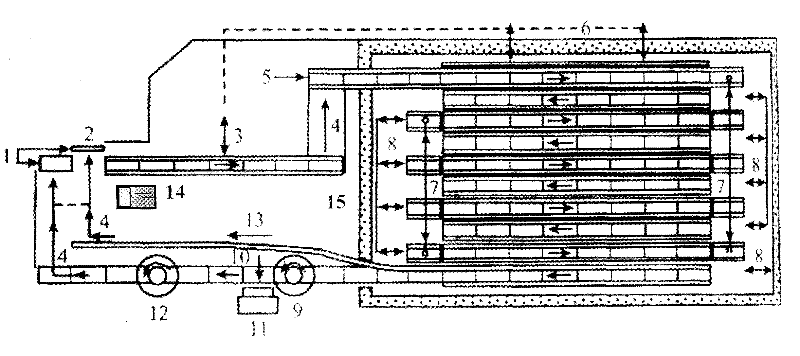

[0017] Such as figure 1 As shown, the hydroponic pasture continuous production device has a general-purpose rectangular overall structure, and the device can be moved on a vehicle. When the pasture is urgently needed, the device can be transported to the country, and it can be produced when it is powered on. The design principle of the device is that the entire operation process is automated, and the size of the hydroponic forage continuous device depends on the production needs. The greenhouse (15) provides the best environment for pasture growth, and is a pasture seed pretreatment and harvesting device outside the greenhouse (15). During operation, the planting tray (1) is evenly sown with forage (2), and then the seeds are pretreated (3), and the elevator (4) pushes the planting tray into the interior of the greenhouse (15), and the nutrient solution spraying and lighting system (6) start work, the germination and growth process of forage seeds begins, and the planting tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com