Method for forming bionic non-smooth surface of casting

A non-smooth surface and casting technology, which is applied in the casting field of castings, can solve the problems of high cost, low efficiency, and the inability to form mold or sand core 3 convex lines, etc., and achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

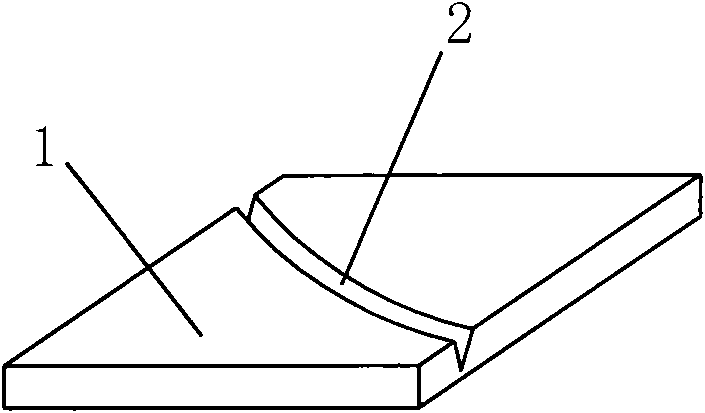

[0022] In this embodiment, the bionic non-smooth surface is formed on the inner wall 11 of the impeller of the complex surface water pump as an example, and the triangular groove 10 of the bionic non-smooth surface is formed, such as Figure 4 As shown, the width a=0.5-3.0 mm, the height b=(1-1.5)a, and the distance c=(1-3)a between the two grooves 10 are designed.

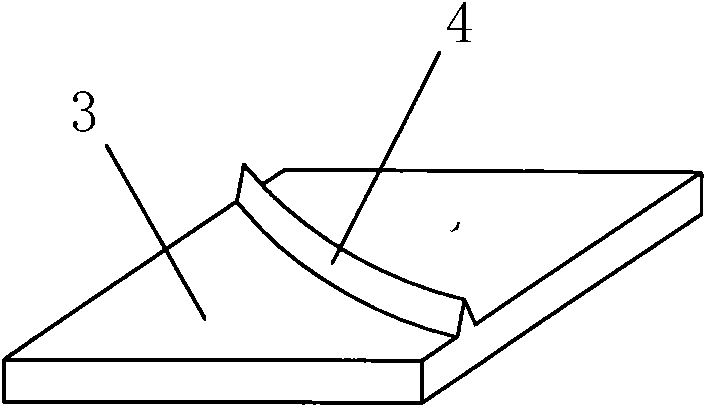

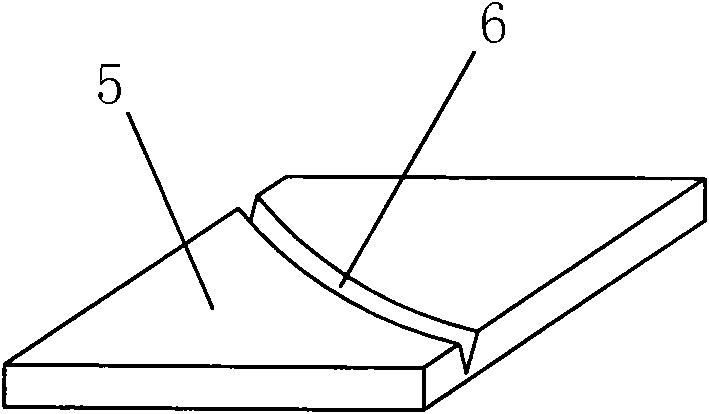

[0023] 1. On the rubber plate 7, cut out a rubber triangular convex strip 8 with the same cross-sectional shape as the triangular groove 10 to be formed on the inner wall 11 of the water pump impeller with complex surface, such as Figure 5 shown;

[0024] 2. The rubber triangular ridge 8 cut out is bonded to the sand core 3 with an adhesive according to the position, direction and radian of the triangular groove 10 to be formed on the casting, and then air-dried and trimmed, such as Figure 6 Shown; In the present embodiment, adhesive is selected latex for use;

[0025] 3. The surface of the rubber triangular c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com