Tin soldering repair method for punch damage of external covering part

A technology for outer covering parts and solder, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increased production costs and increased labor, and achieve the effects of saving costs, saving energy, and reducing damage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

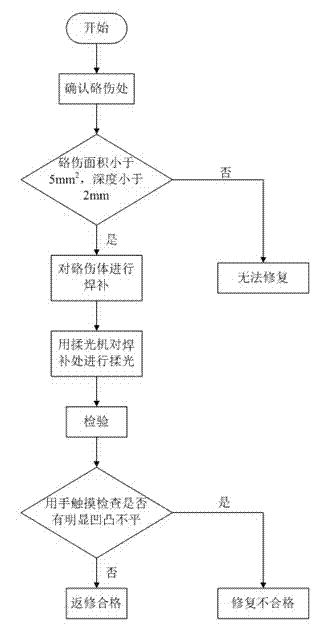

[0020] Such as figure 1 Shown, a kind of method for repairing tin damage of outer covering part, comprises the following steps:

[0021] The first step is to check and confirm the damage of the product, and the damage area is less than 5mm 2 , The depth of the injury is less than 2mm, and it can be repaired. If the area and depth of the wound are greater than the above regulations, it cannot be repaired. Therefore, the operator must make an accurate judgment on the wound, and resolutely cannot repair the area or depth of the wound that exceeds the specified standard, otherwise the unqualified product after repair will flow into the downstream process, which will cause relatively large losses;

[0022] The second step is to use solder to repair the damaged part of the product. When soldering, the solder can evenly cover the damaged part. Do not pile u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com