Fourth shaft device of image measuring instrument

A technology of image measurement and shaft device, which is applied in the field of image measuring instruments, can solve the problems of measurement process error, complex structure of milling cutter handle, inability to measure high-precision coaxiality of products and workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

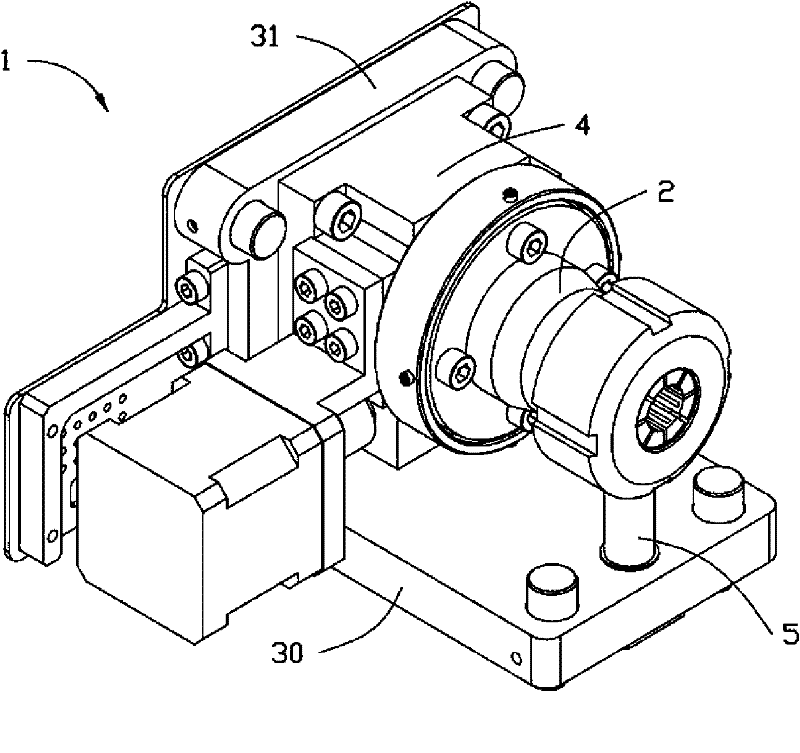

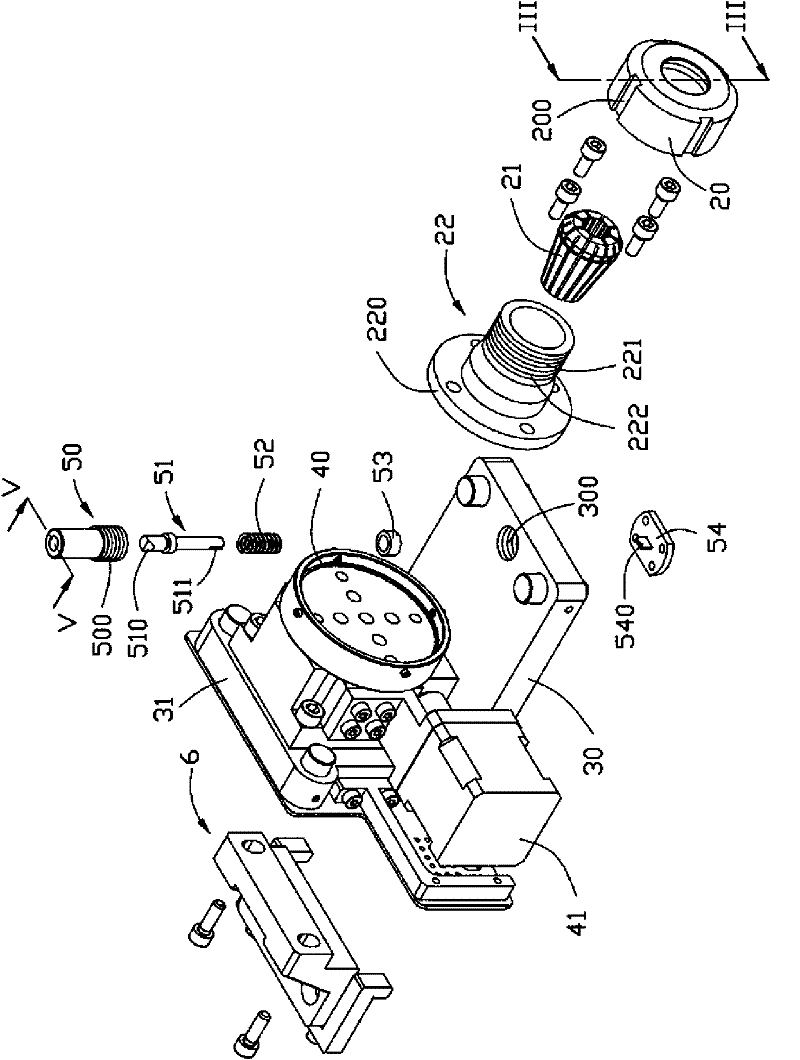

[0016] refer to Figure 1 to Figure 5 , the preferred embodiment of the fourth axis device 1 of the image measuring instrument of the present invention includes a milling tool handle device 2, a horizontal base 30, a vertical base 31 vertically connected to the horizontal base 30, and a high-precision rotating table 4 And elastic workpiece device 5. Wherein, the turbine worm high-precision rotary table 4 is installed on the horizontal base 30 and the vertical base 31 , and the milling tool handle device 2 is connected with the turbine worm high-precision rotary table 4 .

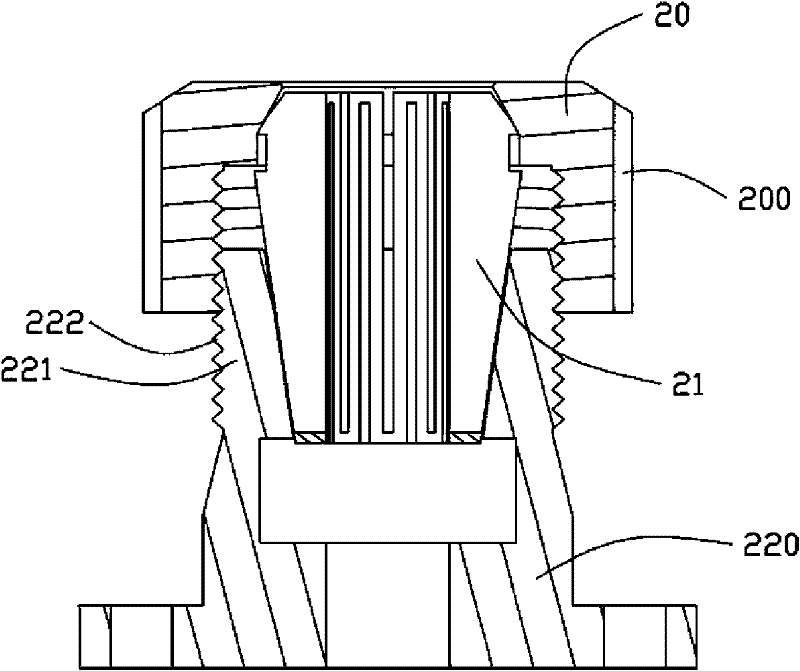

[0017] The turbine worm high-precision rotary table 4 includes a rotating disk 40 and a motor 41 . The milling tool holder device 2 includes a nut 20 , a reducing sleeve 21 and a tool holder 22 . The handle 22 includes a fixing part 220 , an embedded sleeve 221 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com