Device for testing rheological properties of magnetorheological fluid

A technology of magnetorheological fluid and rheological properties, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of increased volume ratio concentration of magnetorheological fluid, large amount of magnetorheological fluid, wall slip effect, etc. , to achieve the effect of strong magnetic field, good verticality and uniformity, and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

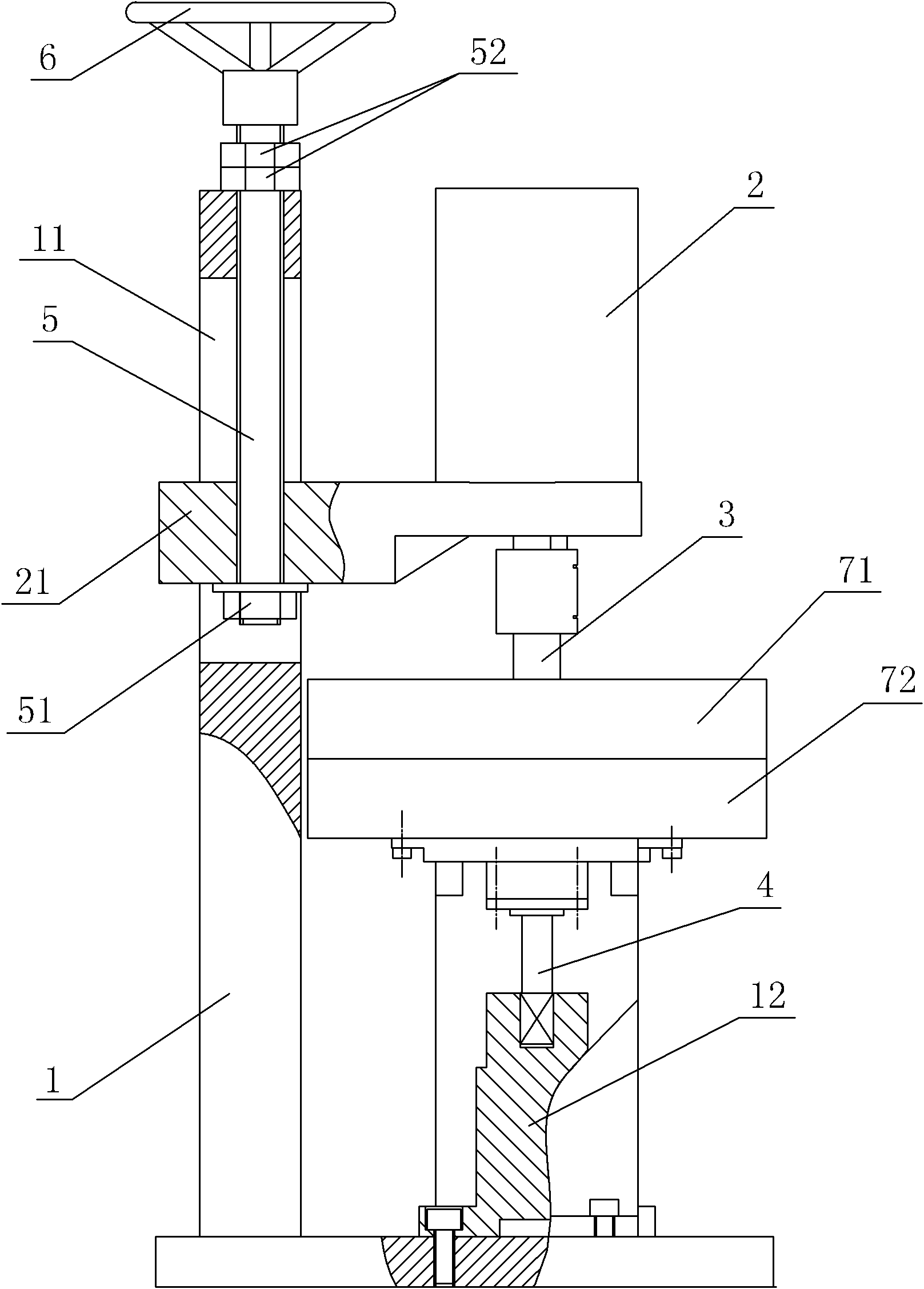

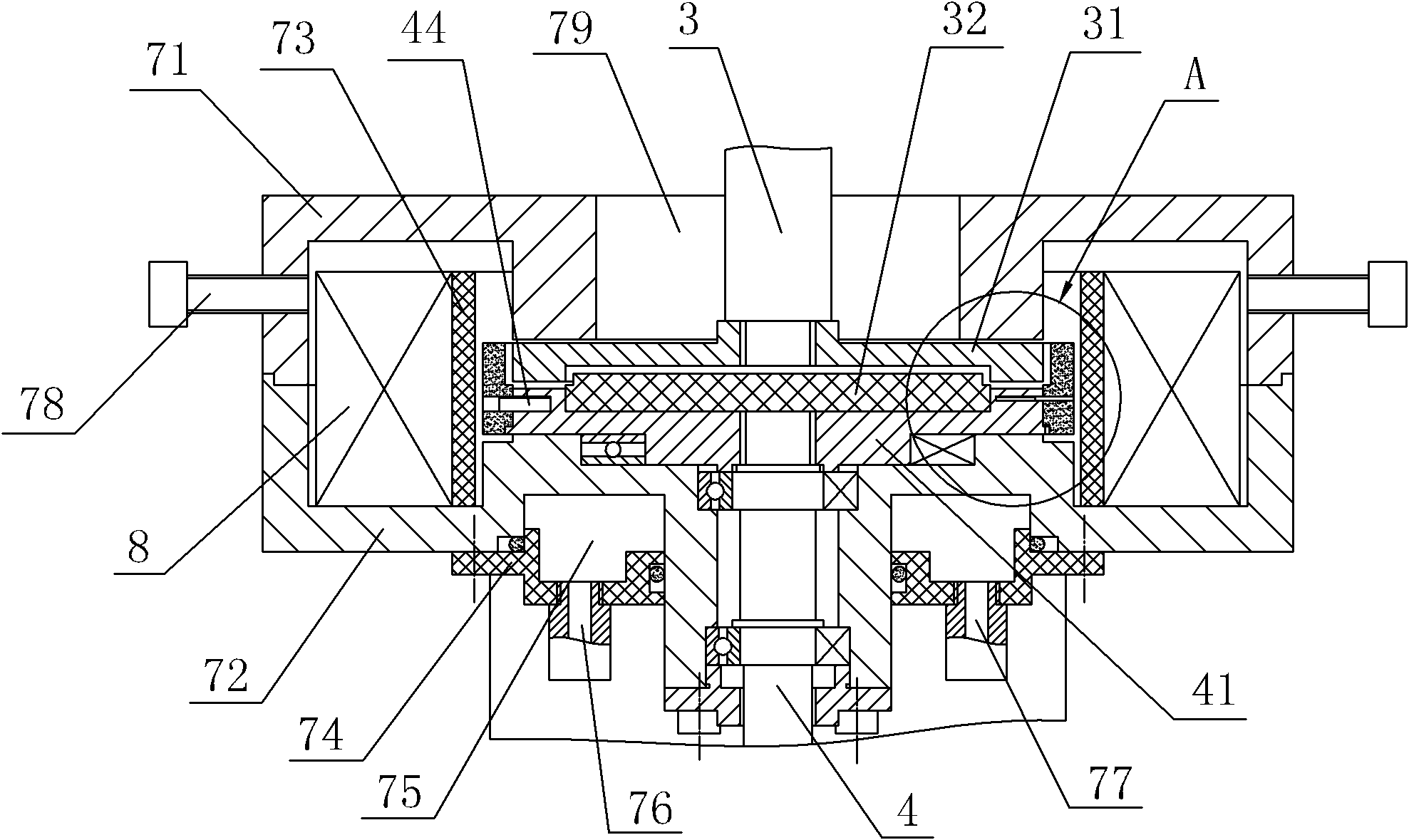

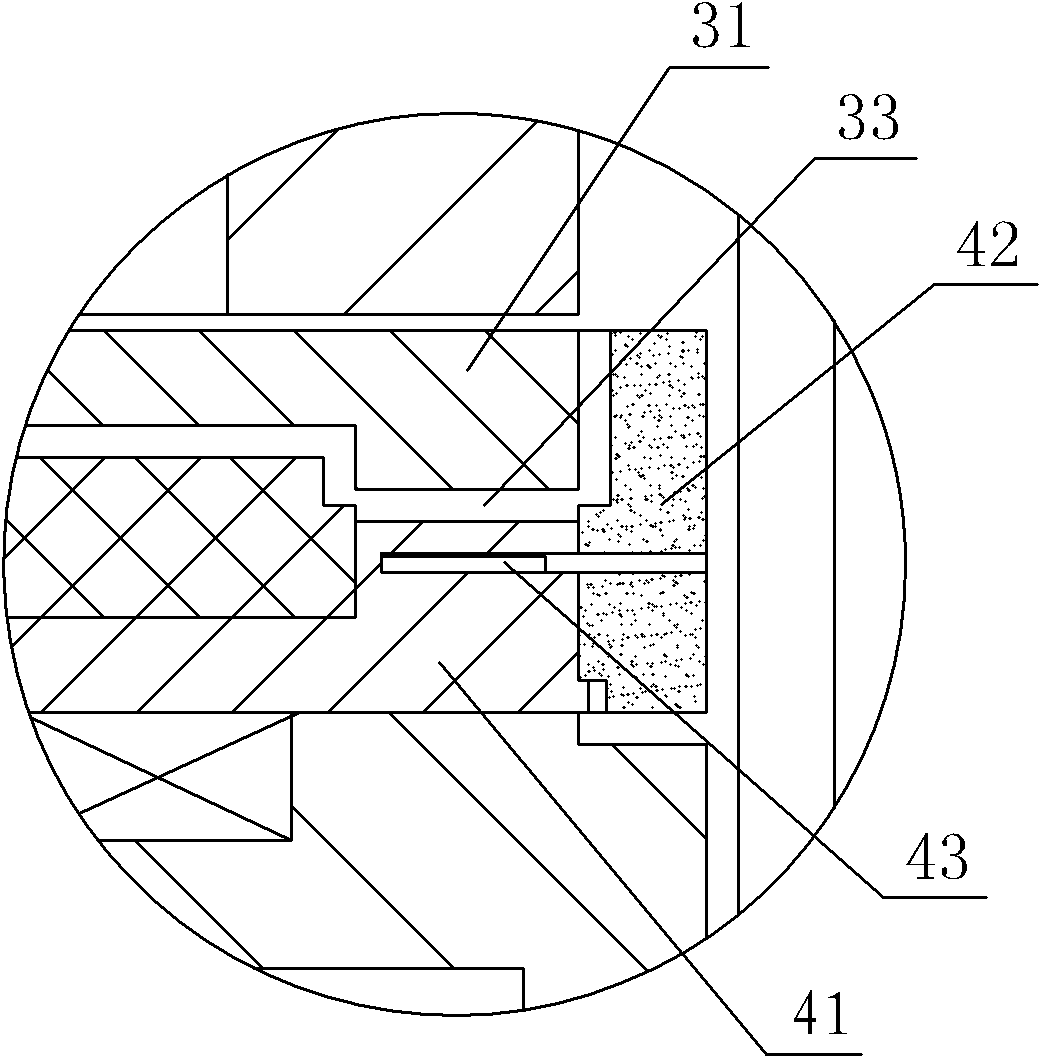

[0017] As shown in the figure, a test device for the rheological properties of magnetorheological fluid includes a bracket 1, a motor 2, a rotating shaft 3, a stationary shaft 4, a screw rod 5, a hand wheel 6, a motor bracket 21 and an upper cover 71, The housing formed by the lower cover 72, the bracket 1 is provided with a lifting hole 11, the upper end of the screw mandrel 5 is fixedly connected with the hand wheel 6, the screw mandrel 5 extends into the lifting hole 11 and is screwed with the motor bracket 21, the screw mandrel 5 The upper end of the screw rod 5 is screwed with a double nut 52, the lower end of the screw rod 5 is screwed with a positioning nut 51, the motor 2 is fixedly connected on the motor bracket 21, the lower cover 72 is fixed on the bracket 1, and the lower end of the rotating shaft 3 stretches into the housing and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com