Natural magnetizing phenomenon-based austenitic stainless steel plastic damage quantitative detection method

A technology of austenitic stainless steel, quantitative detection method, applied in the direction of material magnetic variables, measuring devices, instruments, etc., can solve the problem of not giving a consistent interpretation, and achieve the effect of no surface treatment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

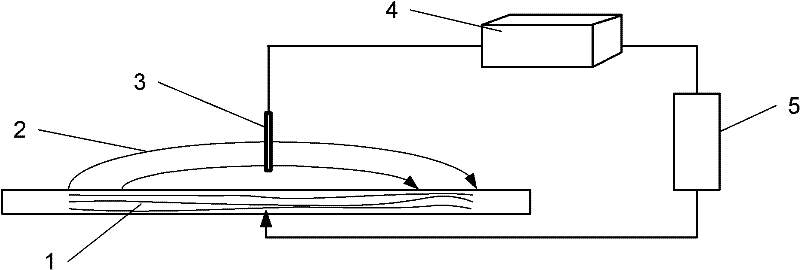

[0026] refer to figure 1 As shown, the measurement method of the present invention is based on the damage-induced magnetization phenomenon, that is, the damage-plastic deformation 1 inside the material will cause the leakage field 2 near the material to change. This change is picked up by the probe 3 of the micro-magnetic field measuring instrument 4 (fluxgate magnetometer) to obtain the damage-induced leakage magnetic field distribution signal; the measured leakage magnetic field distribution signal is processed by the inverse problem reconstruction optimization algorithm to obtain the internal magnetization of the material The distribution results are compared with the established damage-magnetization calibration curve 5 to determine the degree of plastic damage inside the material.

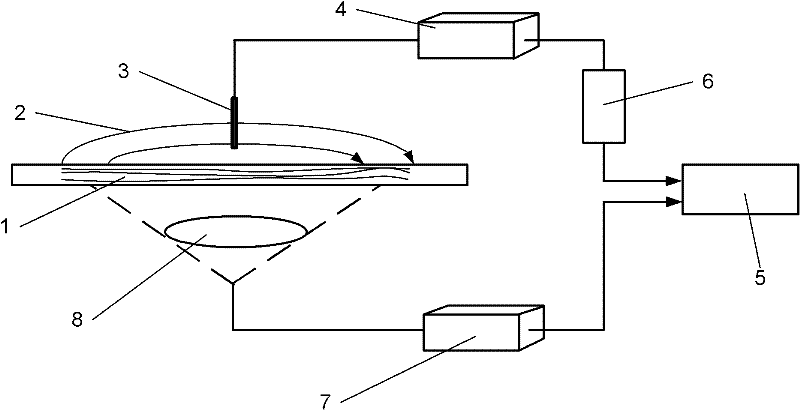

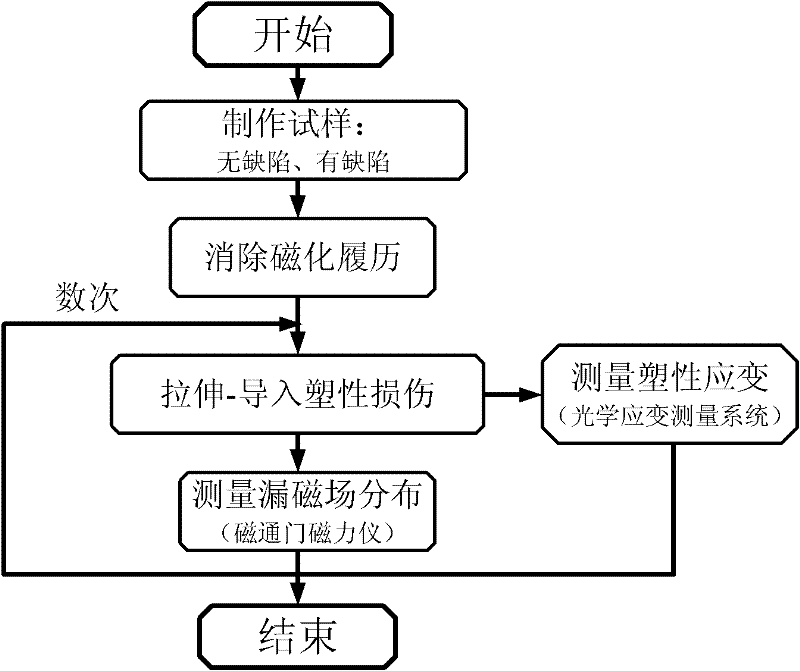

[0027] refer to figure 2 As shown, various forms of tensile specimens are made; the tensile fatigue testing machine is used to apply different loads to introduce damage 2 in the specimen; dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com