Image processing box

A technology of image processing and developing unit, which is applied in electrography, optics, instruments, etc. It can solve the problems affecting the accuracy of state identification information of image processing box, and achieve the effect of high accuracy and precise detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: an image processing box using a cam slider device

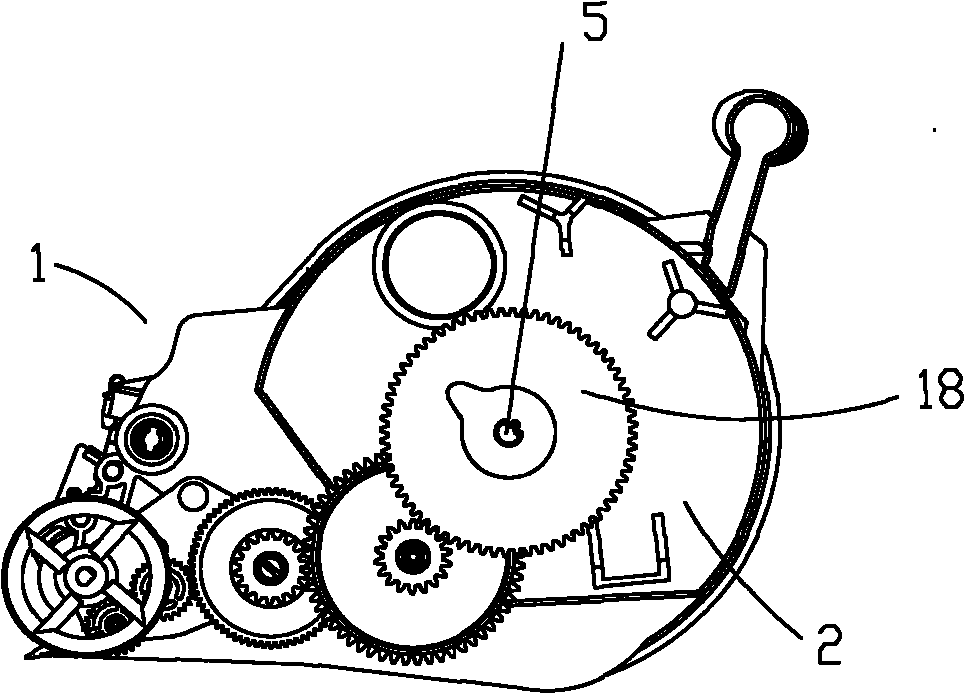

[0029] figure 1 The shown developing unit 1 mainly includes an agitator shaft 5 supported on both side walls of the developing unit 1 , a powder bin 2 containing toner inside, and an assembly 18 installed outside the side wall of the developing unit 1 .

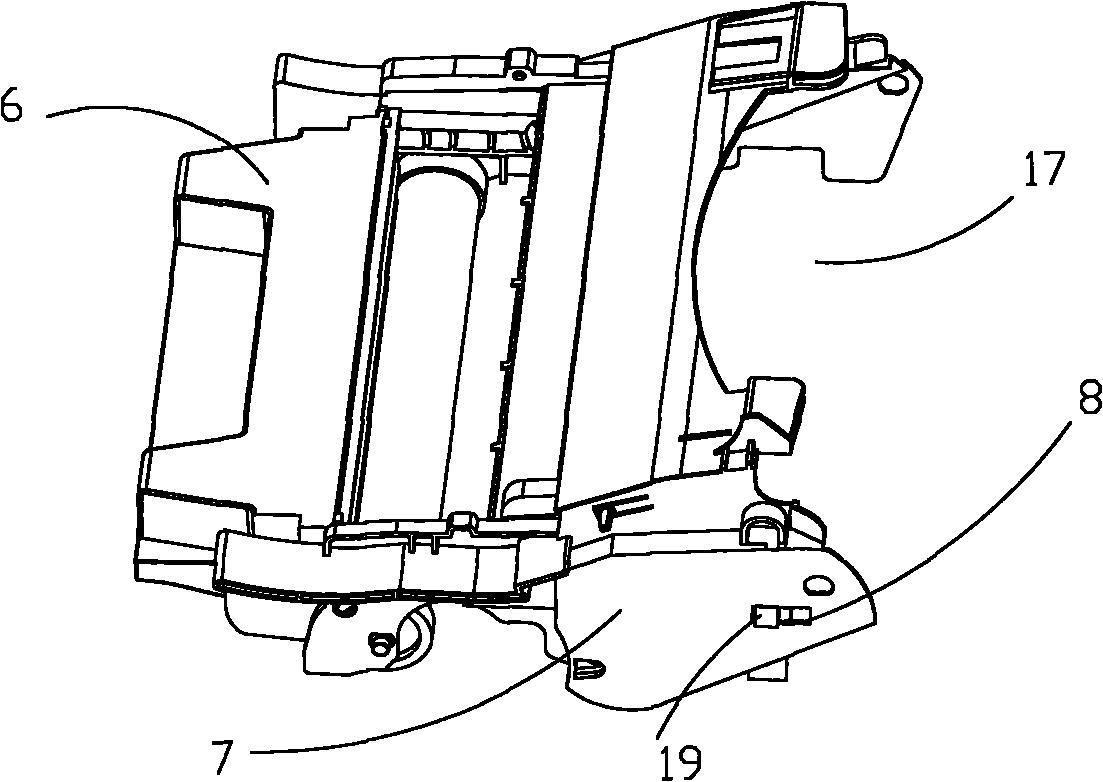

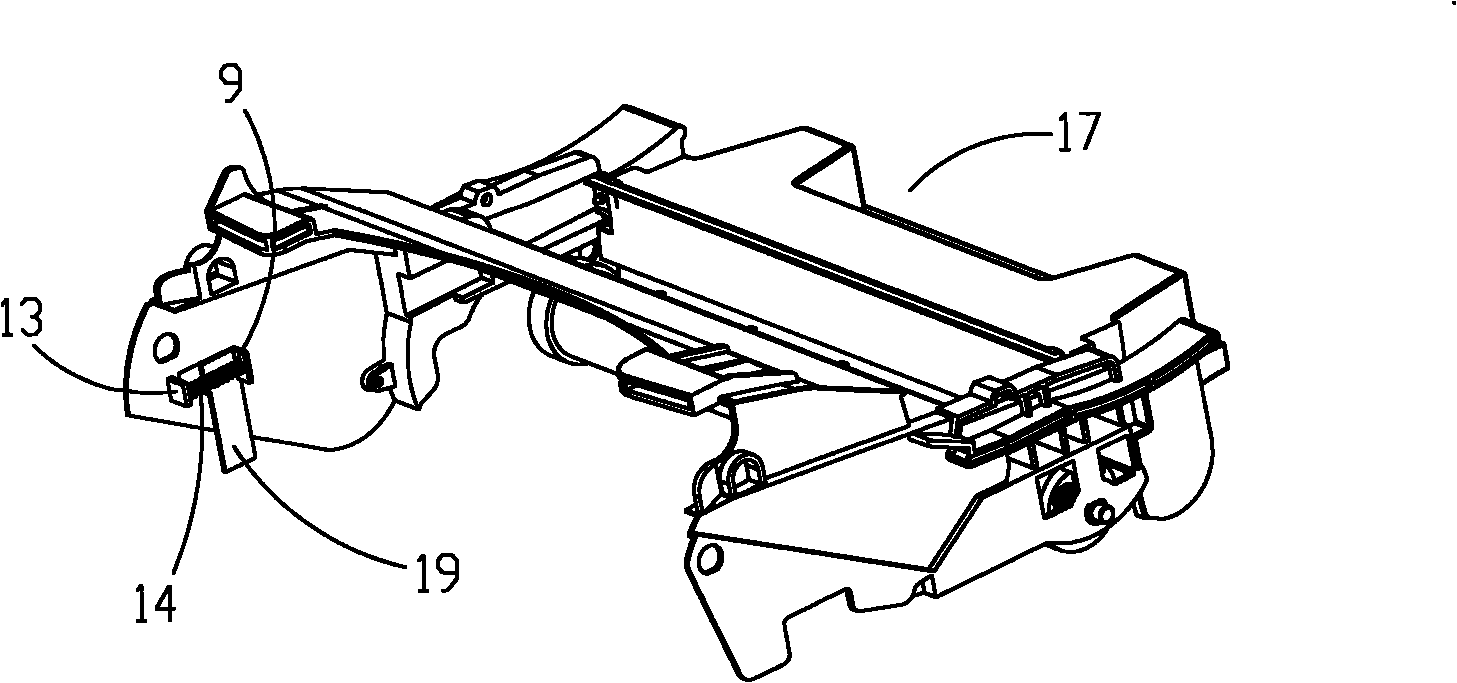

[0030] figure 2 , image 3 The photosensitive drum cartridge 17 shown mainly includes a waste toner bin 6, a slider cover sheet assembly 19, a spring 9, and a side wall 7 for assembling the slide block cover sheet assembly, wherein the wall 7 includes a rectangular window-shaped Slider track 8 has a support block 13 perpendicular to the inner wall surface on the inner wall surface of wall 7, and a cylindrical protrusion 14 is used for bearing spring 9 on one side of 13. From two perspective views in different directions, it can be seen that the installed slider block assembly 19 is installed on the side wall 7 of the photosensitive drum cartridge 17 ...

Embodiment 2

[0038] Embodiment 2: Image processing box adopting rack and pinion device

[0039] Figure 11 , Figure 12 As shown, the gear assembly 23 is integrally formed, including a half-key hole 20 for matching the shaft of the stirring rack in the developing unit, a driving gear 21 for driving the shaft of the stirring rack to rotate, and a sector gear 22, wherein the sector The gear angle β determines the opening time of the shutter 26 in the rack-slider assembly 27 at the position of the code reader.

[0040] The slider assembly 27 is integrally formed, including an opaque shielding sheet 26, a cylindrical projection 25 perpendicular to the plane of the shielding sheet 26 for connecting springs (not shown), a slide block 40, and a slide block 40 There is a flange above and below respectively, which is used for the positioning of the slider 40 in the track, so as to prevent it from slipping out of the assembly track. The slider track and the spring connection supporting member match...

Embodiment 3

[0041] Embodiment 3: Image processing box adopting slider crank device

[0042] Figure 13 The shown crank assembly 30 is integrally formed, and it includes a half-key hole 28 for matching the shaft of the stirring rack in the developing unit, a driving gear 39 for driving the shaft of the stirring rack to rotate, and a drive gear 39 on the outer surface of the driving gear 39. The shaft 29 is extended.

[0043] Figure 14 The slider assembly 37 shown includes an opaque mask 36 , a shaft 35 extending perpendicular to the plane of the mask, and a slider 38 . Wherein, there is a flange respectively above and below the slide block 38, which is used for the positioning of the slide block in the track, so as to prevent it from slipping out of the assembly track. The slider track matched with the slider assembly 37 is also located on one side wall of the photosensitive drum cartridge casing, and will not be described here.

[0044] Figure 15 The connecting rod 33 shown include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com