LED device with improved LED color rendering index (CRI) and manufacturing method thereof

A technology of LED devices and color rendering index, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of poor color rendering index of luminous spectrum, and achieve the effect of improving color rendering index, improving luminous flux, and warm color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

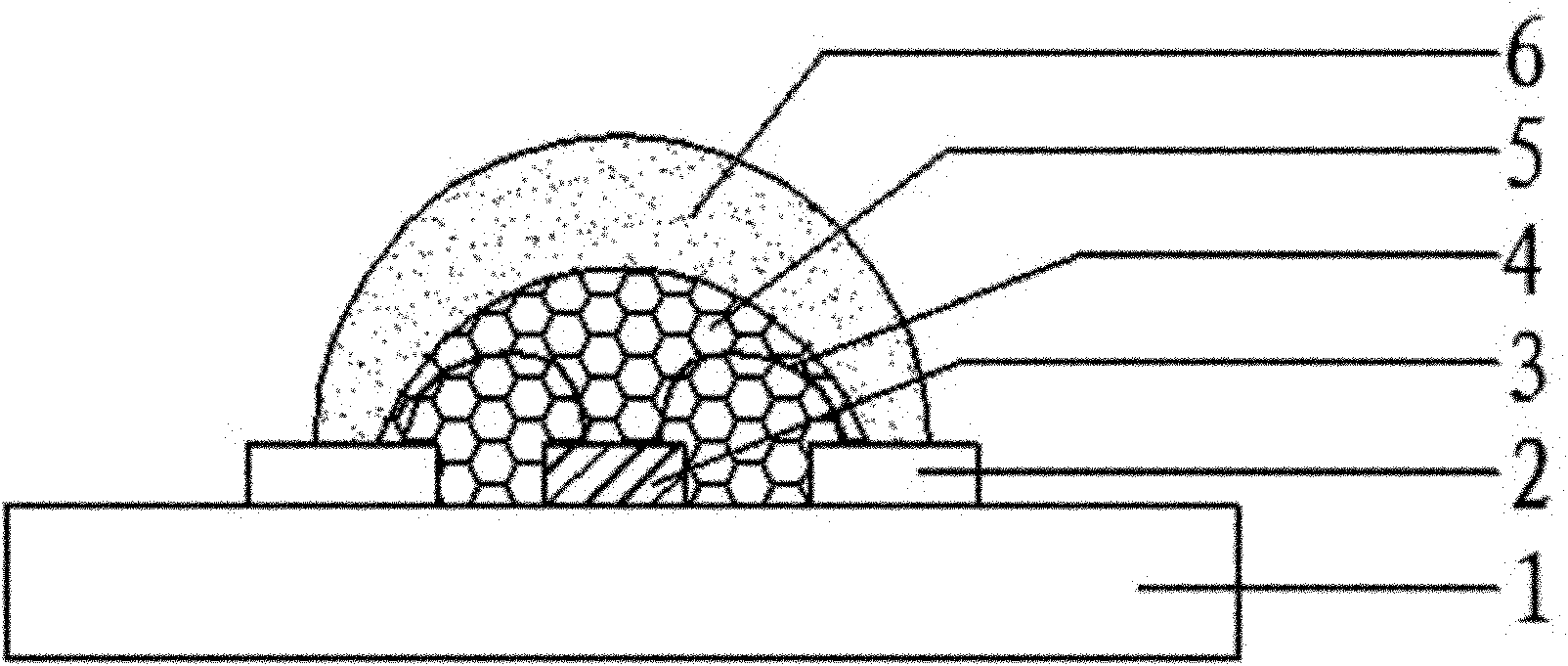

[0021] 1. Chip inspection: inspect the LED chip 3 to check whether it meets the specifications;

[0022] 2. Crystal expansion: use a crystal expansion machine to expand the film of the bonded LED chip 3, so that the distance between the LED chips 3 becomes larger, which is convenient for spinning;

[0023] 3. Glue dispensing: Dot insulating glue on the place where the LED chip 3 needs to be placed on the LED bracket 1, so as to facilitate the connection of the LED chip 3;

[0024] 4. Thorn crystal and solid crystal: stab the expanded LED chip 3 on the LED bracket 1 with a crystal pen and fix it with silver glue;

[0025] 5. Welding gold wire: connect LED chip 3 and electrode pin 2 with gold wire 4;

[0026] 6. Dot phosphor powder doped with organic material: Dot phosphor powder doped with organic material on the surface of LED chip 3 and the area between the LED chips;

[0027] 7. Drying: Dry the fluorescent powder doped with organic materials in a drying oven to form a silv...

Embodiment approach 2

[0032] 1. Chip inspection: inspect the LED chip 3 to check whether it meets the specifications;

[0033] 2. Crystal expansion: use a crystal expansion machine to expand the film of the bonded LED chip 3, so that the distance between the LED chips 3 becomes larger, which is convenient for spinning;

[0034] 3. Glue dispensing: Dot insulating glue on the place where the LED chip 3 needs to be placed on the LED bracket 1, so as to facilitate the connection of the LED chip 3;

[0035] 4. Thorn crystal and solid crystal: stab the expanded LED chip 3 on the LED bracket 1 with a crystal pen and fix it with silver glue;

[0036] 5. Welding gold wire: connect LED chip 3 and electrode pin 2 with gold wire 4;

[0037] 6. Dot the phosphor powder: Dot the phosphor powder on the surface of the LED chip 3 and the area between the LED chips 3;

[0038] 7. Drying: drying the phosphor powder in a drying oven to form a phosphor powder layer 5;

[0039] 8. Add organic material encapsulating gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com