Failure guiding safety principle-based contactor automatic switching control method

A safety-oriented, contactor-oriented technology, applied in the direction of emergency power supply arrangements, electrical components, circuit devices, etc., can solve problems such as contactor loosening, fault expansion, equipment input power failure, etc., to reduce maintenance costs and maintenance difficulties, reduce Potential safety hazards of circuits and effects of high power supply reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

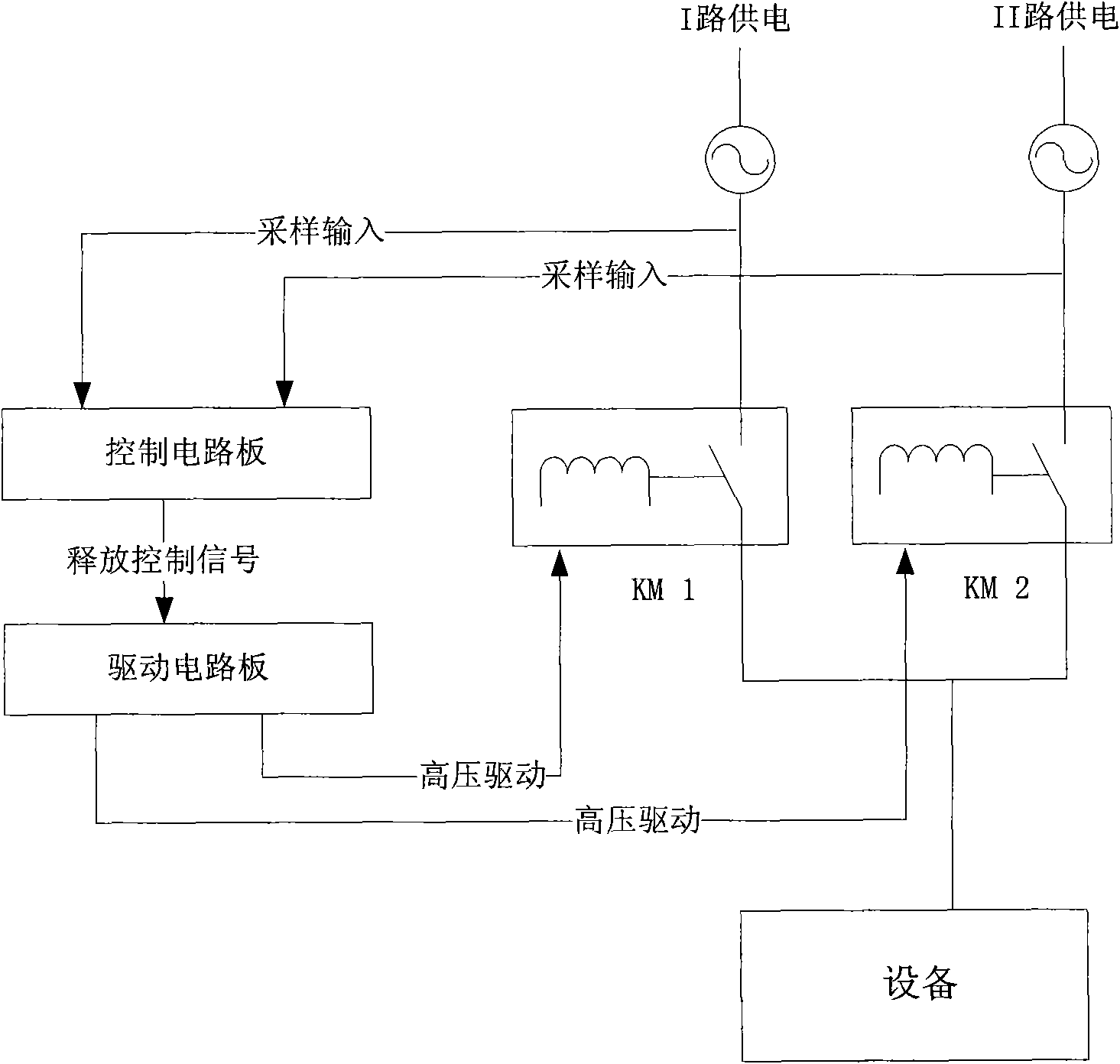

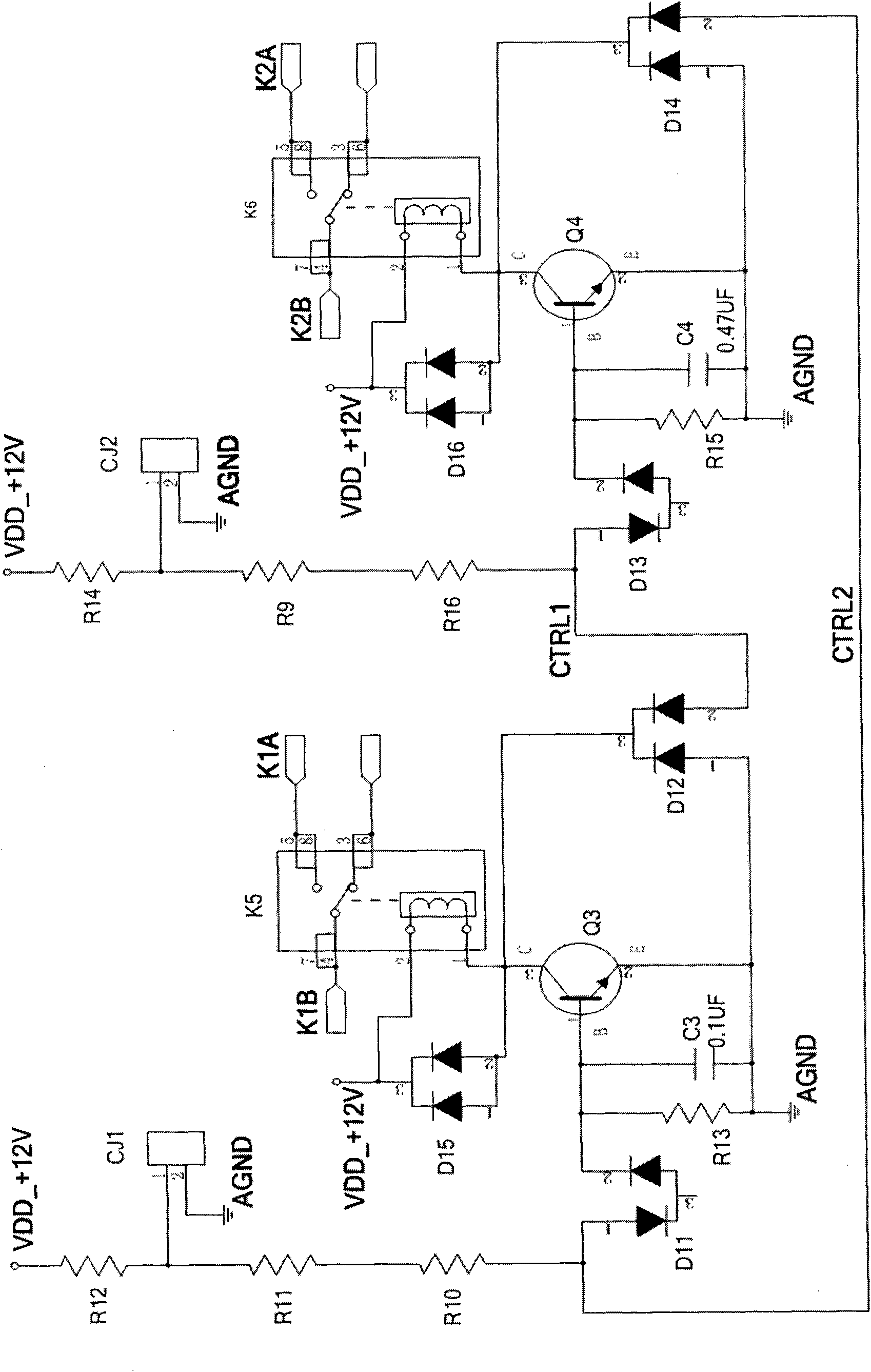

[0017] A specific embodiment of the present invention, which is based on figure 1 In the power supply system structure shown, the contactors KM1 and KM2 are respectively connected in series in the main and standby circuits, and the control circuit is separated from the drive circuit. When the control circuit sends a signal to the drive circuit, the drive circuit releases the corresponding contactor; The structure diagram of the specific contactor drive circuit is as follows: figure 2 shown.

[0018] In the figure, K5 and K6 are the control relays of contactors KM1 and KM2 respectively. When K5 is closed, K1A and K1B are connected, and contactor KM1 is closed. When K6 is closed, K2A and K2B are connected, and contactor KM2 is closed. combine. CJ1 and CJ2 are control signal input ports. When the internal pins 1 and 2 are turned on, the control contactor is released, and when pins 1 and 2 are disconnected, the control contactor is pulled in.

[0019] The circuit operation flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com