Low-speed high-torque wide-speed-regulation permanent magnet synchronous motor

A permanent magnet synchronous, high-torque technology, applied to synchronous motors with stationary armatures and rotating magnets, single motor speed/torque control, magnetic circuit rotating parts, etc., can solve the problem of narrow speed range and low speed Torque waste and other problems, to achieve the effect of wide speed regulation range, solve torque waste, easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

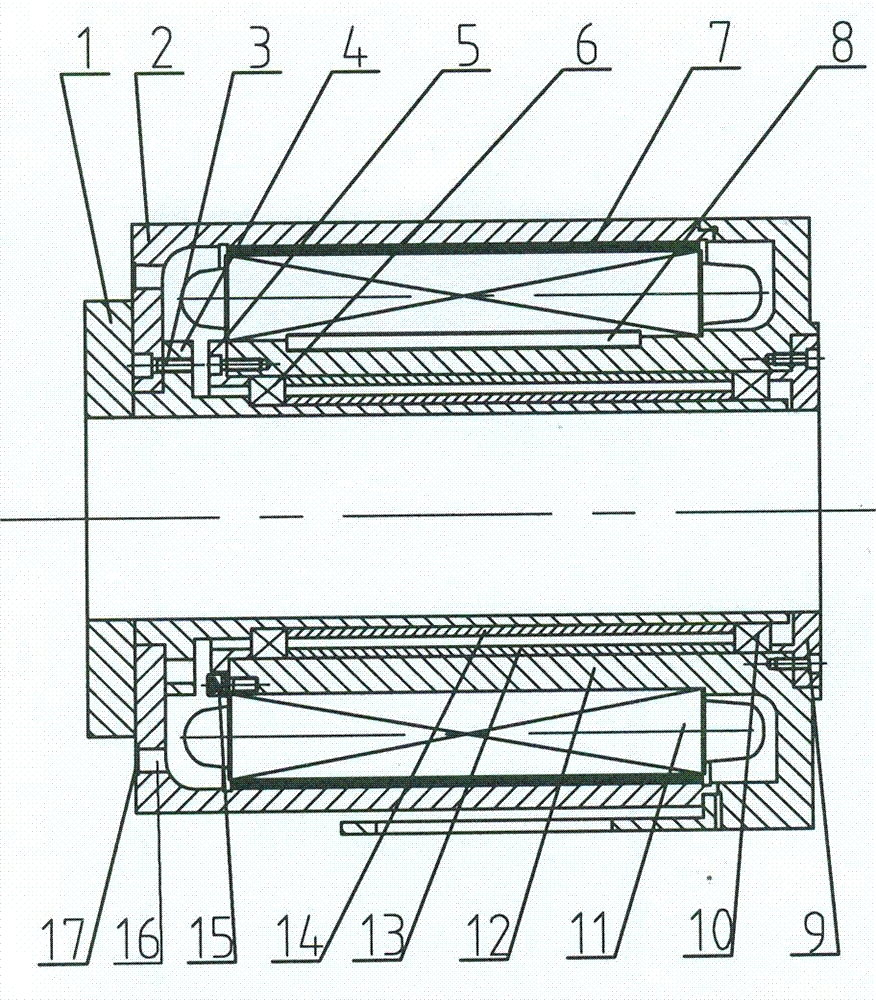

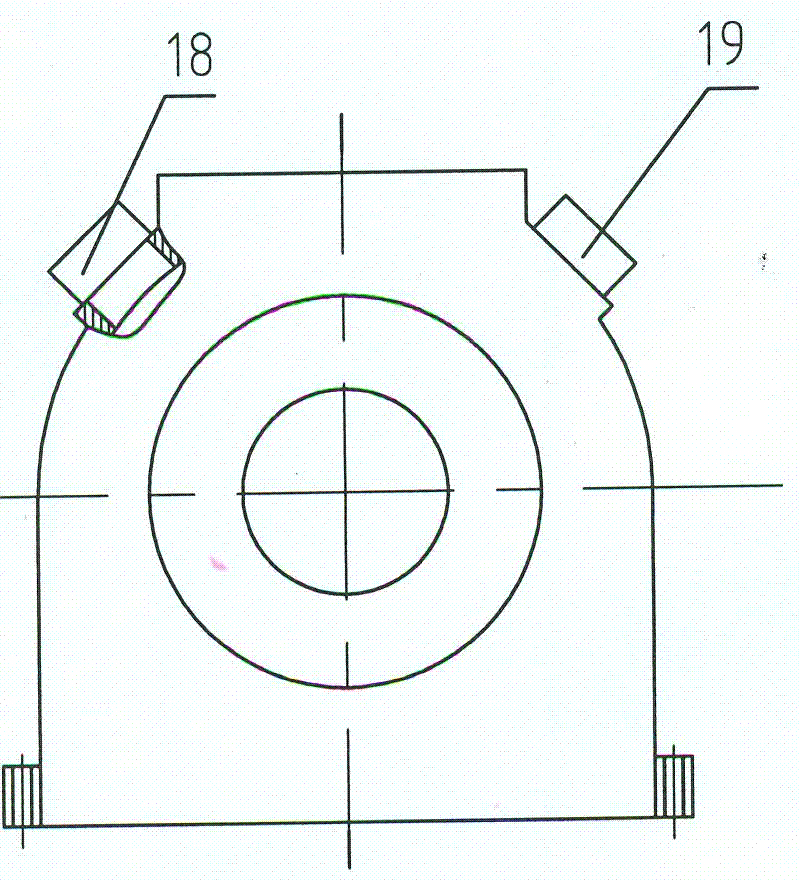

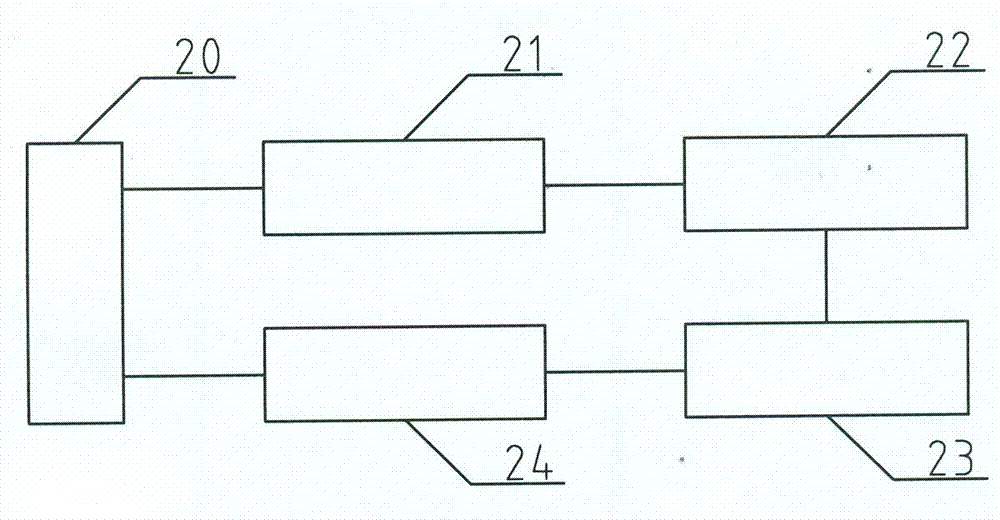

[0019] according to Figure 1-7 The specific structure of the present invention will be described in detail. The permanent magnet synchronous motor designed by the present invention is a low-speed, large-torque and wide-speed-adjustable permanent-magnet synchronous motor suitable for a speed regulation range of 0.1rpm-6000rpm and a rated torque of not less than 300Nm at low speed. It includes a machine base 12 , a stator core 11 with a winding 23 assembled on the machine base 12 , a rotor 2 , an encoder 1 and other components. Among them, the rotor 2 adopts the hollow structure of the outer rotor, and the rotor 2 with the permanent magnet 7 attached to the inner circumference is connected with the hollow bushing 4 and placed outside the stator core 11, and the rotor 2 and the hollow bushing 4 are connected as a whole through the fixing screw 3 . The stator core 11 is connected with the frame 12 through the key 8, and the stator core 11 is compressed by the adjusting screw 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com