Washing machine

A technology for washing machines and clothing, applied in other washing machines, washing machine appliances, control devices of washing machines, etc., can solve problems such as unbalanced changes, inability to infer vibration with high precision, and increased motor load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

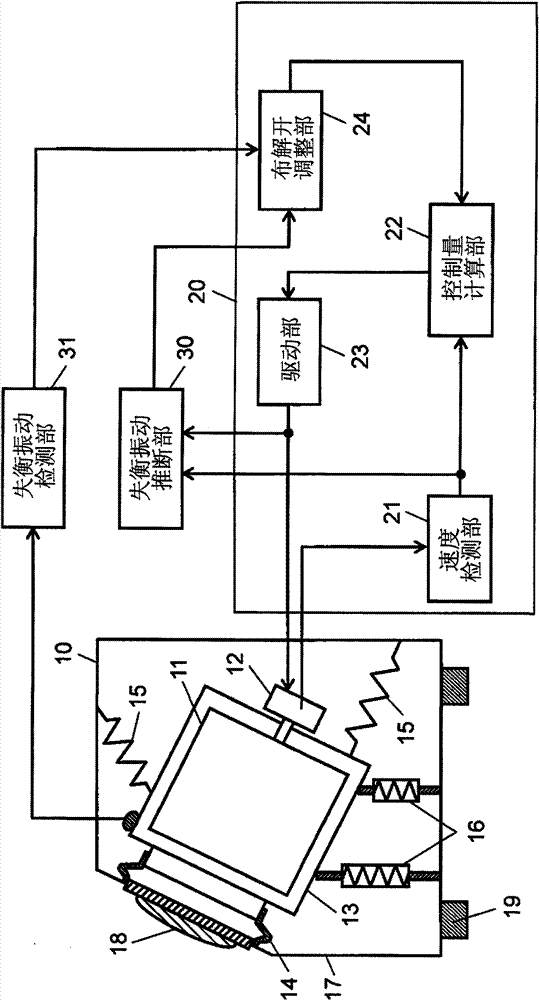

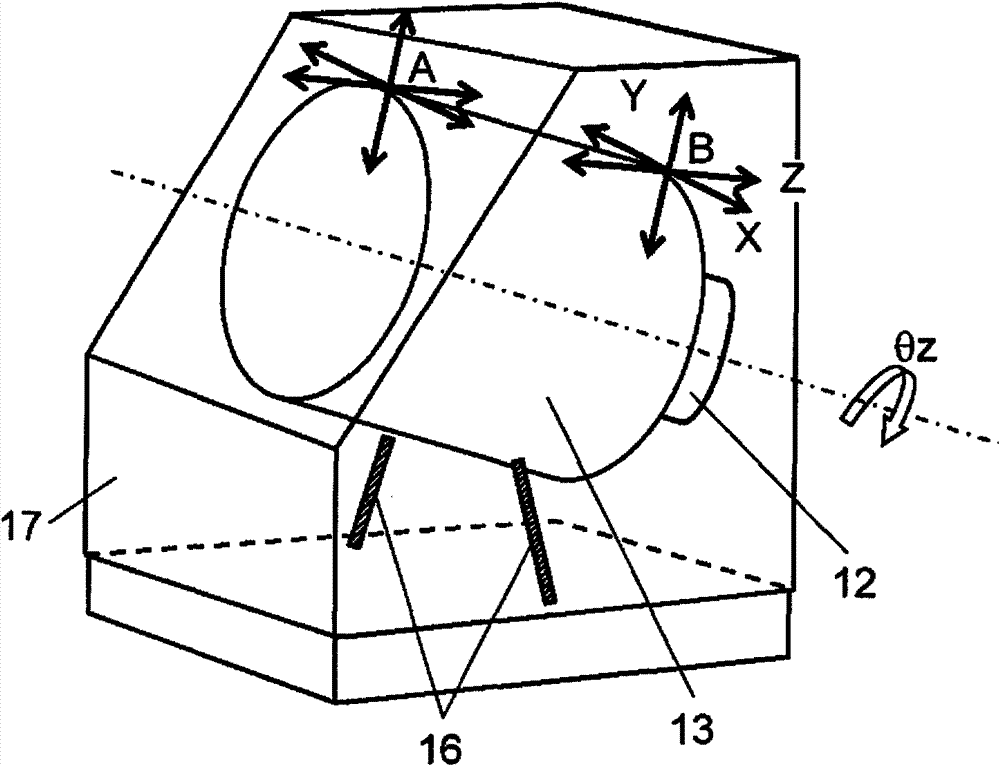

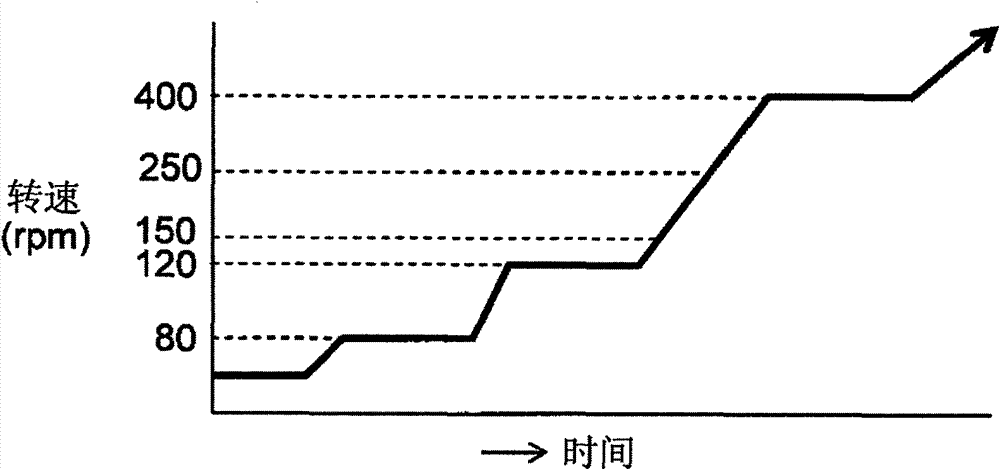

[0024] figure 1 It is a structural block diagram of the washing machine in Embodiment 1 of this invention. figure 2 It is a schematic structure drawing of this washing machine. image 3 It is a sequence diagram showing the rotational speed at startup in the dehydration process of the washing machine. Figure 4 It is an explanatory diagram of the vibration characteristics at the time of start-up in the dehydration process of the washing machine. Figure 5 It is a block diagram showing the control unit of the washing machine in detail.

[0025] exist figure 1 Among them, the washing machine mechanism unit 10 has a rotary drum 11 as a washing tub for accommodating and rotating laundry such as laundry. The motor 12 which rotates the rotary drum 11 while controlling the speed is comprised by the brushless motor. The washing machine mechanism unit 10 has a receiving tub 13 in which a rotary drum 11 is rotatably housed and water and clothes as laundry can be put therein. The w...

Embodiment approach 2

[0068] Figure 6 It is a structural block diagram of the washing machine control device according to Embodiment 2 of the present invention. exist Figure 6 Among them, the basic structure is the same as that of Embodiment 1, and the same reference numerals are assigned to the same components, and the contents of Embodiment 1 are referred to for the detailed description.

[0069] This embodiment differs from Embodiment 1 in that the control unit 20 has a rotational speed correcting unit 25 that controls the rotational speed of the motor 12 in the following manner based on signals from the unbalance vibration detection unit 31 or the unbalance vibration estimation unit 30 , that is, the rotation of the motor 12 is decelerated without stopping. In addition, a cloth unwinding instruction unit 26 is provided for instructing the cloth unwinding adjustment unit 24 to perform the cloth unwinding operation by using the rotational speed correction unit 25 to decelerate the rotation wi...

Embodiment approach 3

[0074] Figure 7 It is a structural block diagram of the washing machine control device according to Embodiment 3 of the present invention. exist Figure 7 Herein, the basic structure is the same as that of Embodiment 1, and the same reference numerals are attached to the same components, and the contents of Embodiment 1 are cited as the detailed description.

[0075] The difference between this embodiment and Embodiment 1 is that it has a dehydration rotation speed determination part 27, and this dehydration rotation speed determination part 27 controls the dehydration rotation speed according to the signal of the unbalance vibration detection part 31 or the unbalance vibration estimation part 30 (in this embodiment, it is speed below 400rpm).

[0076] Utilizing the signals of the unbalanced vibration detecting unit 31 and the unbalanced vibration estimating unit 30 using a 3D sensor, it is possible to detect unbalanced vibration and unbalanced amount not only in the consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com