Improved fuel cell stack flow hood air flow using air distribution device

A fuel cell stack, fuel cell technology, applied in fuel cells, fuel cell grouping, fuel cell additives, etc., can solve problems such as increased complexity and unsatisfactory, achieve size and mass reduction, prolong service life, temperature The effect of gradient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0189] The teachings of fuel cells and fuel cell stack assemblies are well known to those of ordinary skill in the art and include in particular US 6794075, WO 02 / 35628, WO 03 / 075382, WO 2004 / 089848, WO 2005 / 078843, WO 2006 / 079800 , WO 2006 / 106334, WO 2007 / 085863, WO 2007 / 110587, WO 2008 / 001119, WO 2008 / 003976, WO 2008 / 015461 and WO 2008 / 053213, all of which are hereby incorporated by reference in their entirety.

[0190] A summary of the reference signs used herein is given before the claims.

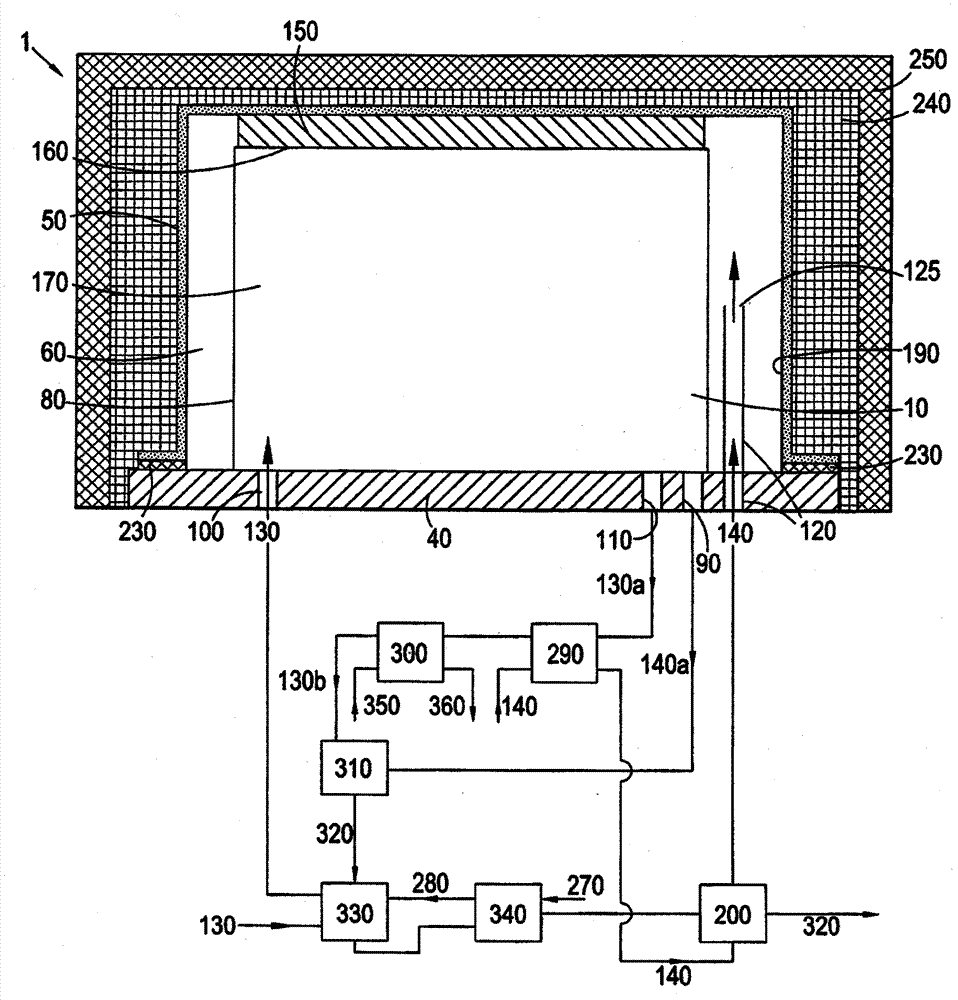

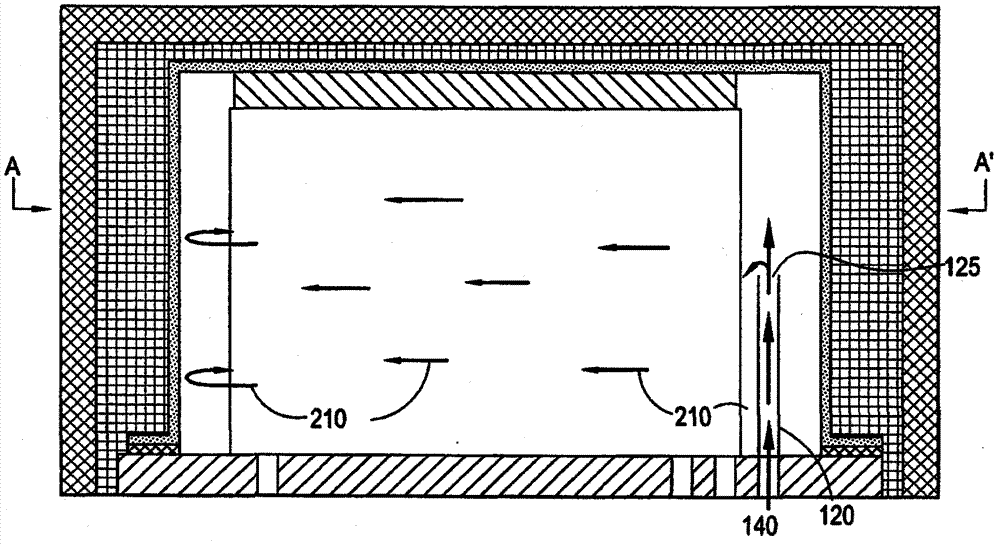

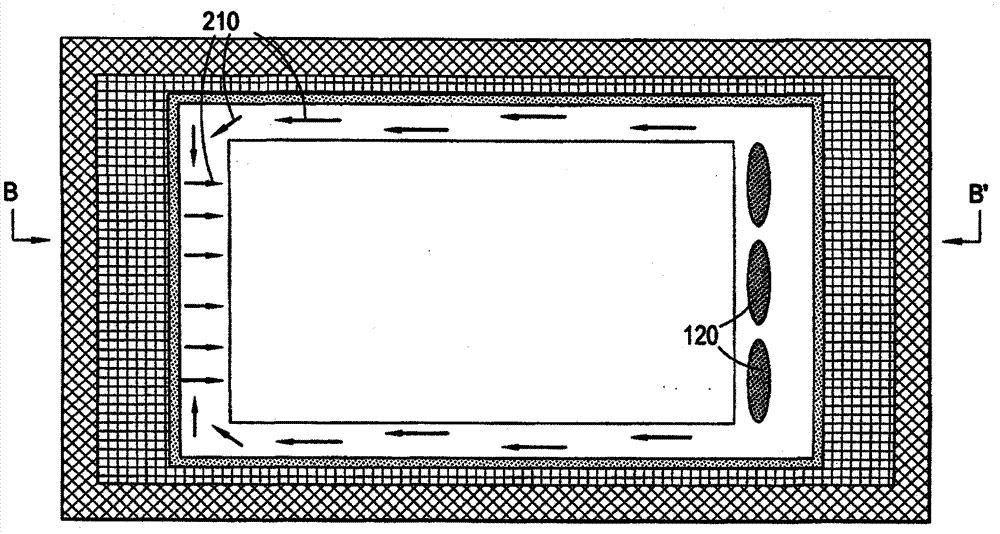

[0191] In the first embodiment of the fuel cell stack assembly 1, the solid oxide fuel cell stack 10 is assembled from a plurality of fuel cell stack layers 20, and each fuel cell stack layer 20 includes a fuel cell 30 (in other embodiments For example, not shown, each fuel cell stack 20 includes a plurality of fuel cells 30). Each fuel cell includes an anode 31, an electrolyte 32, and a cathode 33, wherein the anode 31, the electrolyte 32, and the cathode 33 are mounted on a fuel cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com