Wiring board with built-in electronic component and method for manufacturing the wiring board

A technology of electronic components and manufacturing methods, which is applied in the fields of printed circuit manufacturing, multilayer circuit manufacturing, semiconductor/solid-state device manufacturing, etc., can solve the problems of circuit board warpage and different thermal expansion rates, and achieve warpage prevention and excellent quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

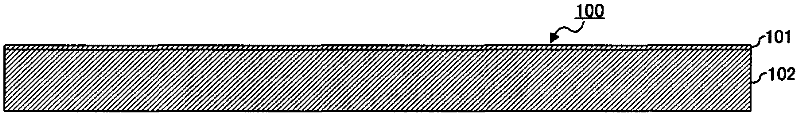

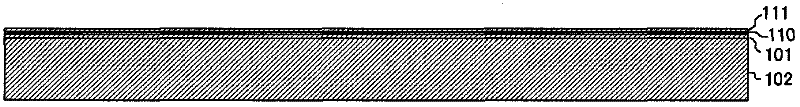

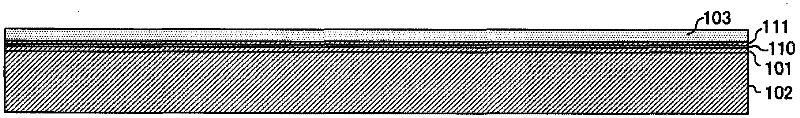

[0057] Next, a wiring board with a built-in electronic component and a manufacturing method thereof according to an embodiment of the present invention will be described with reference to the drawings.

[0058] Figure 4F It is a schematic sectional view of wiring board 1 with built-in electronic components of this embodiment. This wiring board 1 with built-in electronic components can be used, for example, as a core substrate or the like of a multilayer printed wiring board.

[0059] The circuit board 1 with built-in electronic components is composed of electronic components 2, insulating material 3, underfill material 4, filling resin 5, conductive patterns 40, 50 in the inner layer, solder resist layer 112, conductive patterns 60, 70 in the outer layer, and connection terminals 80. , The via-hole conductor 90 is formed.

[0060] The electronic component 2 is a flip chip and has a plurality of bumps 20 arranged in an area array type. The bump 20 is, for example, a stud-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com