Multi-purpose edge folding device

An edge folding device and its predecessor technology are applied in the field of knitted fabric sewing, which can solve the problems of low work efficiency, large labor, and difficulty in guaranteeing the quality of finished woven bags, and achieve the effects of simple structure, reduced labor intensity, and easy processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and embodiment of description:

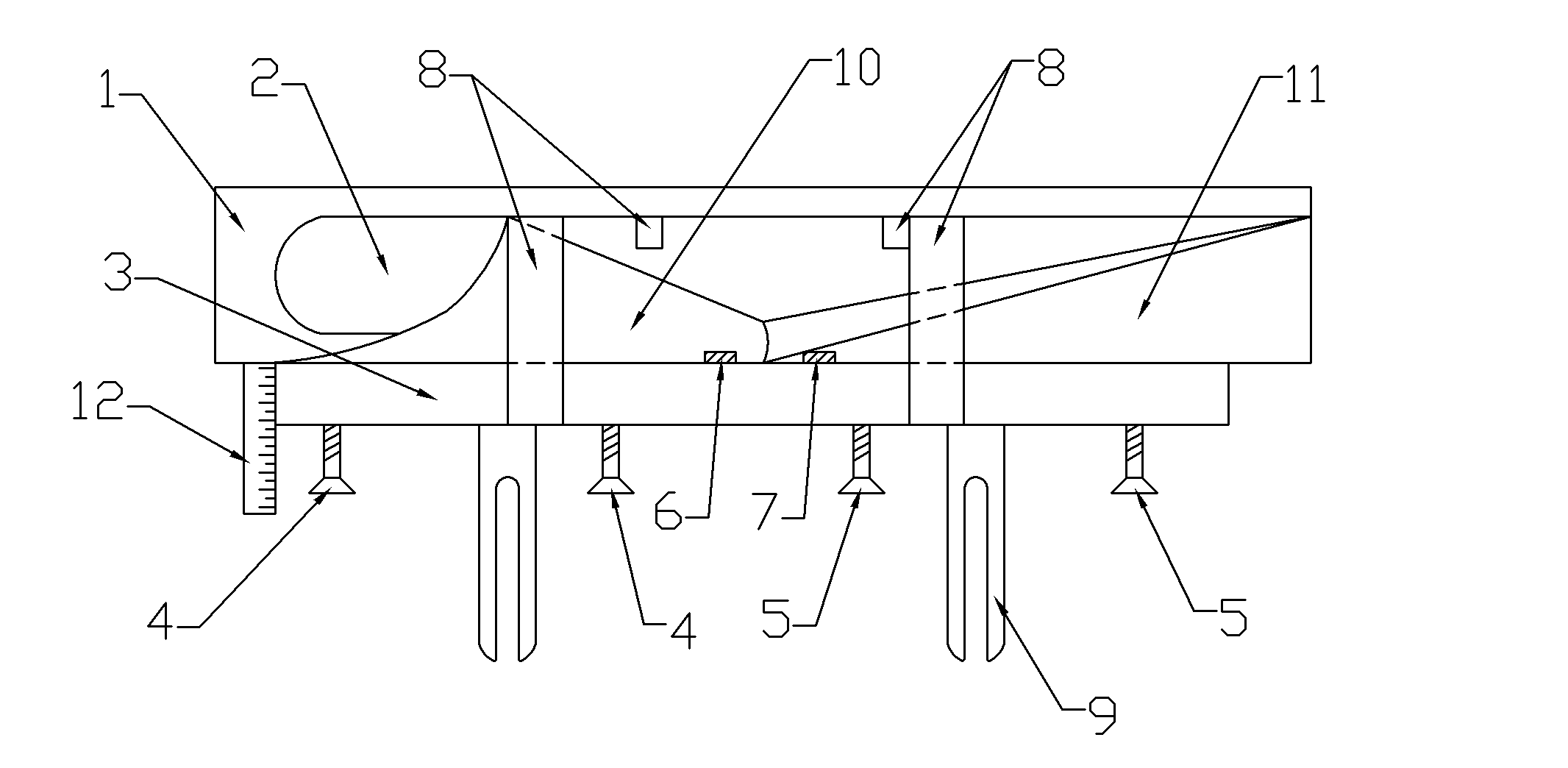

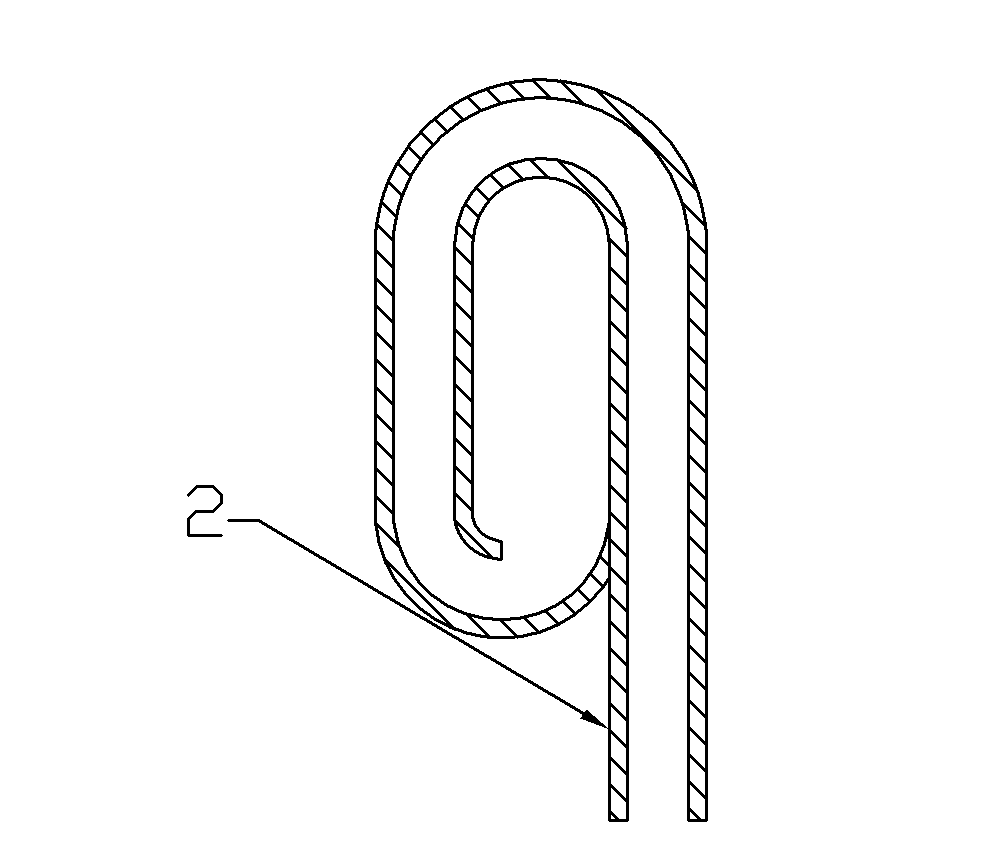

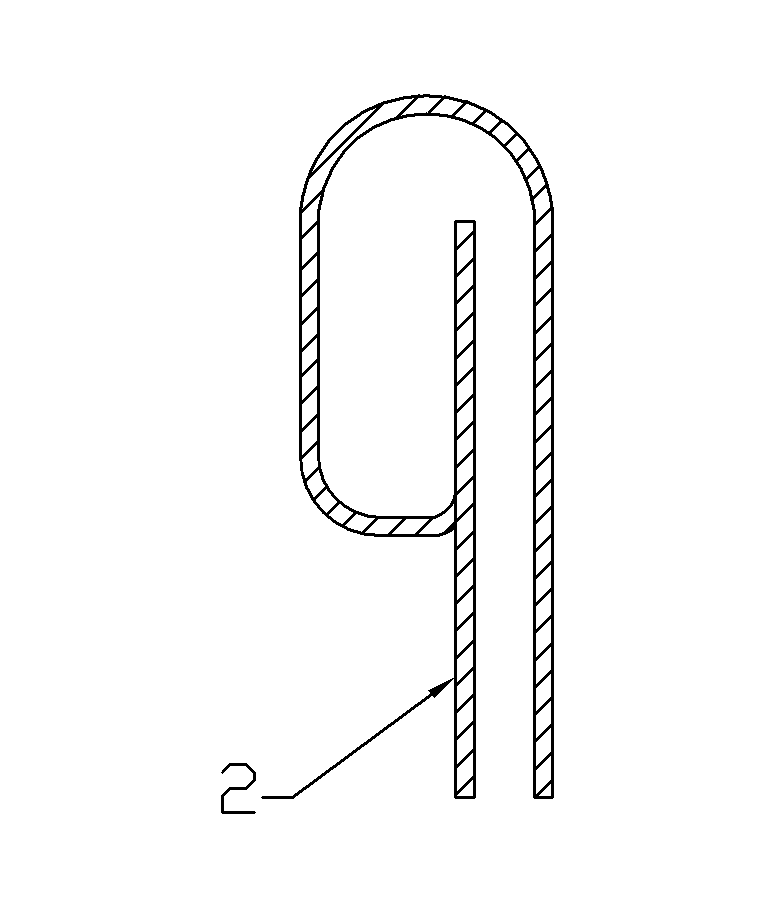

[0018] like figure 1 , figure 2 and image 3 shown. The multi-purpose edge folder includes the main body of the edge folder and the frame 3. The main body of the edge folder includes a bottom plate 1, an upper plate 2, a front body 10 and a rear body 11; the bottom plate 1 and the upper plate 2 are fixedly installed on the frame 3 , the upper plate 2 is fixed by the upper plate fixing hanger 8, the front body 10 forms a flexible connection with the pinch frame 3 through the front body adjusting fastening bolt 4, and the rear body 11 forms a flexible connection with the pinch frame 3 through the rear body adjusting fastening bolt 5 , the outer side of the frame 3 is provided with a fixed fork plate 9; the back body 11 is provided with a curling guide section and a shaping section in sequence from front to back; The integral section is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com