Improved rotary engine structure

A technology for improving structure and engine, applied in the direction of rotary piston engine, rotary or oscillating piston engine, mechanical equipment, etc., can solve the problems of constant volume, short stroke, pressure difference, force output limitation, etc., and achieve easy fine-tuning and reduce clearance. error, the effect of improving acceleration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

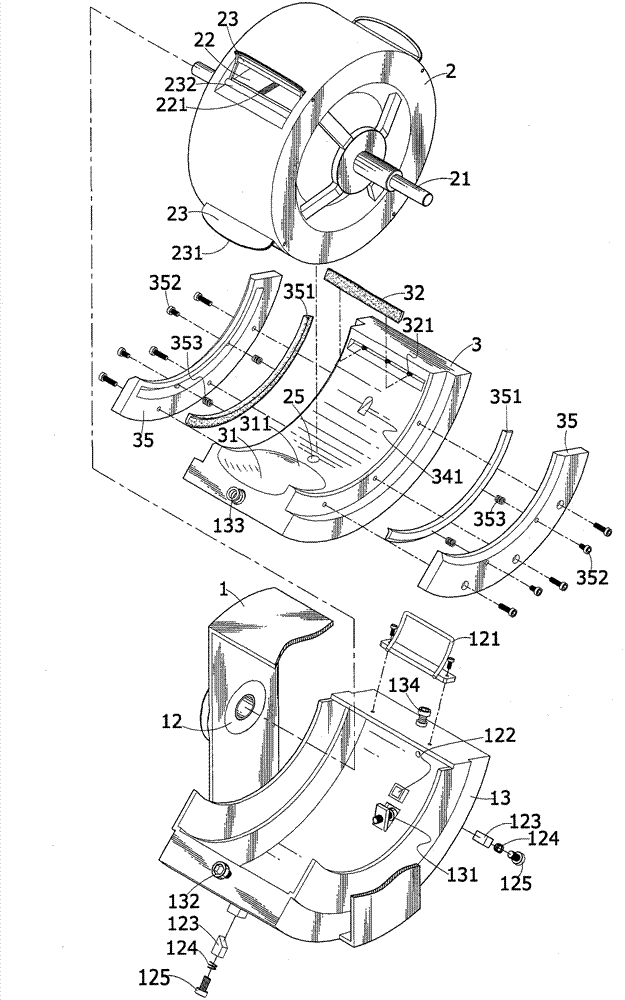

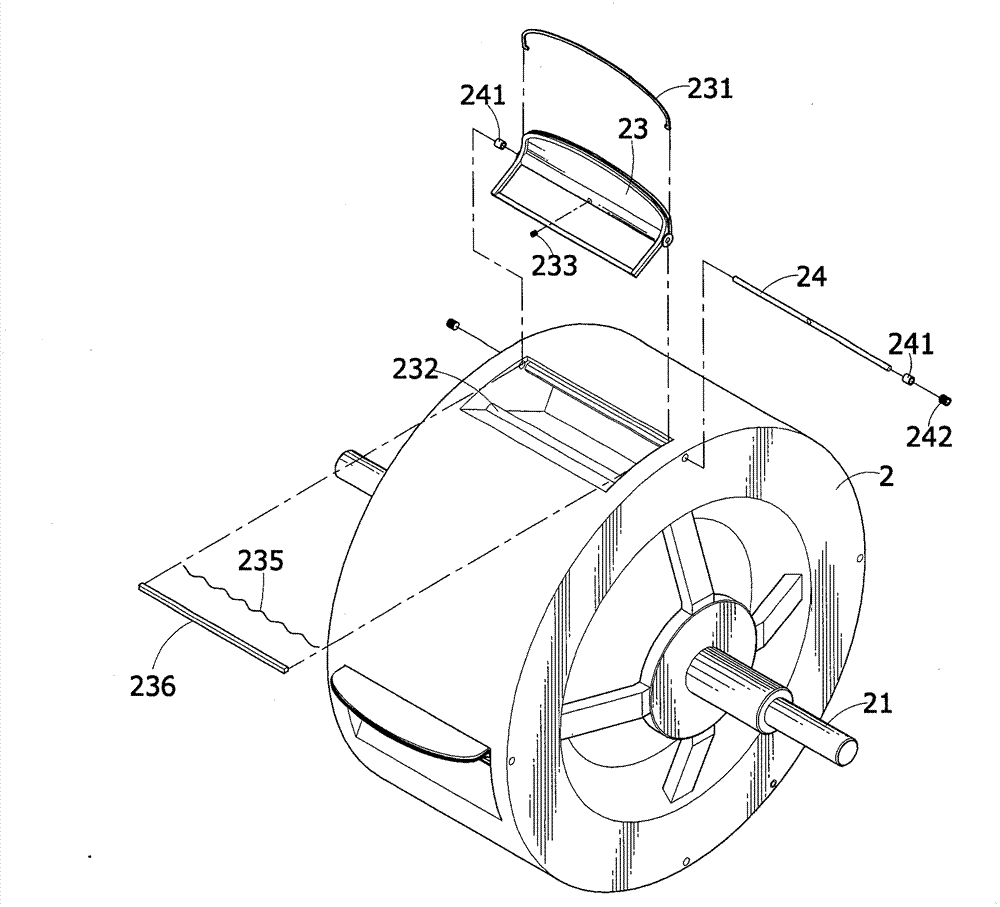

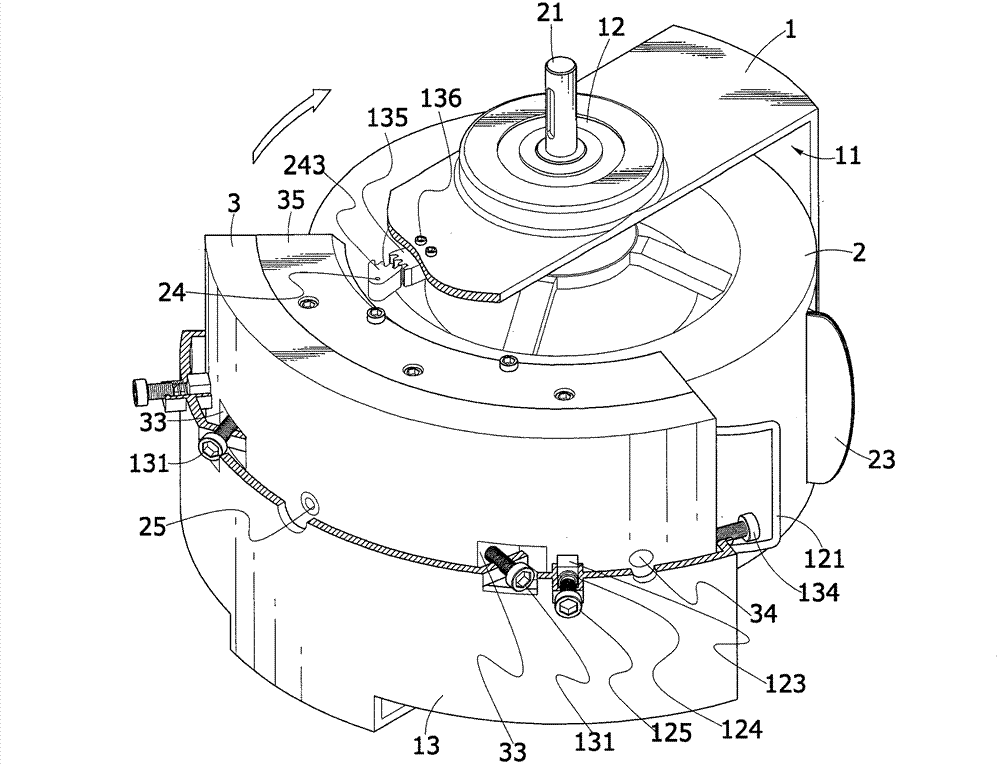

[0027] According to the engine structure of the present invention, the compression stroke in the four strokes of the traditional engine is removed, so fuel, mixed gas, high-pressure air, etc. must be provided by the outside world, please refer to Figure 1 to Figure 6 Or can choose suitable energy air compressor to match this engine, must at first turn steam wheel 2 (not marked) with starter motor, continue by main shaft 21 direct drive compressor, low ignition point fuel, as fuels such as liquefied petroleum gas, gasoline first pass through The evaporator or carburetor is mixed with air and atomized, and then inhaled by the air inlet of the compressor for compression, and the temperature rise output is directly introduced into the air inlet 34 of the engine, and is automatically injected into the combustion chamber 22 by the pressure of the mixed gas body , the inner side of the air inlet 34 is provided with a concave groove 341 which can prolong the intake time. The groove 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com