Capacitor detector

A detection device and capacitor technology, which is applied to capacitor testing, measurement devices, measurement device casings, etc., can solve the problems of reduced detection efficiency, reduced repeat positioning accuracy, low work efficiency, etc., so as to improve detection efficiency, reduce waiting time, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

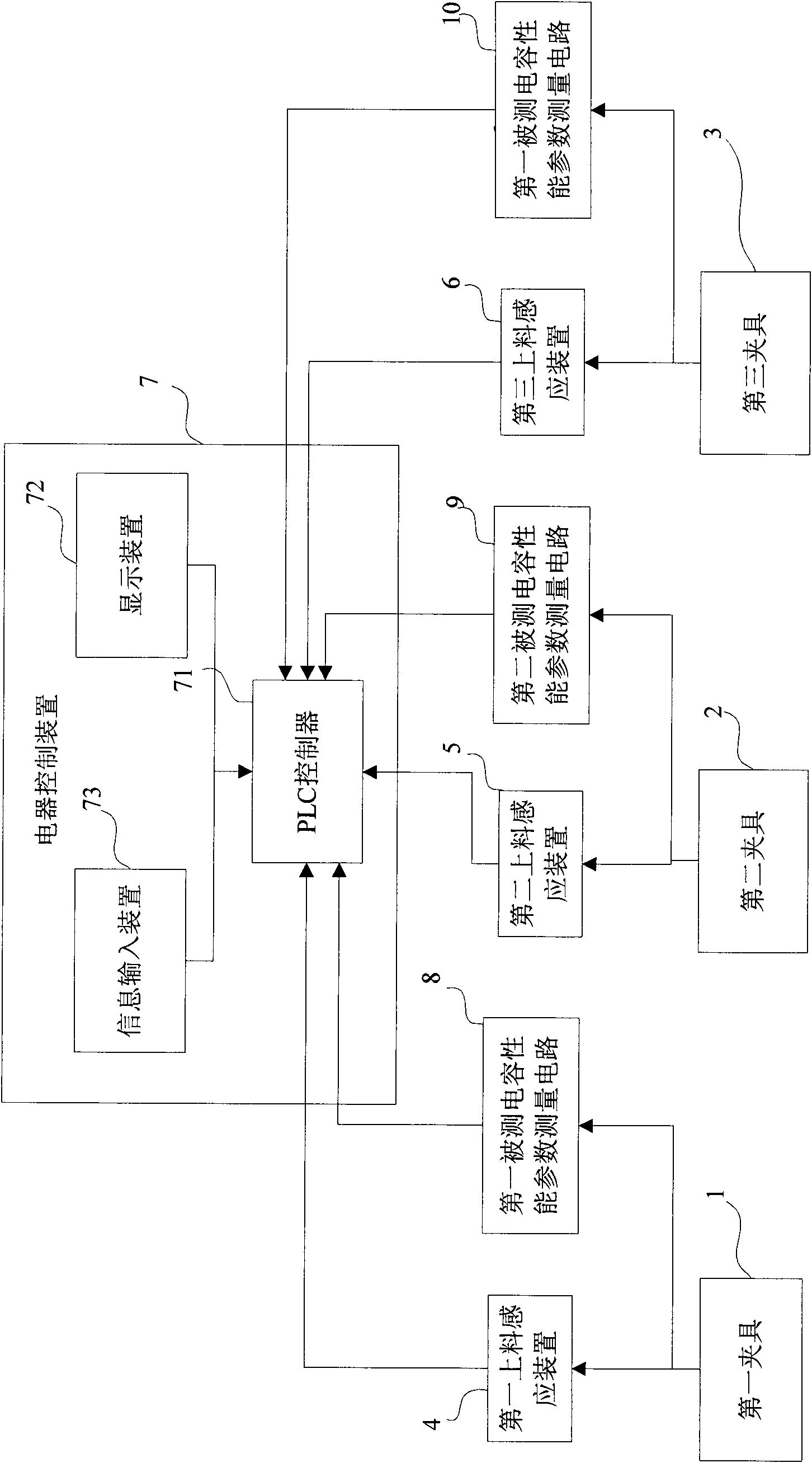

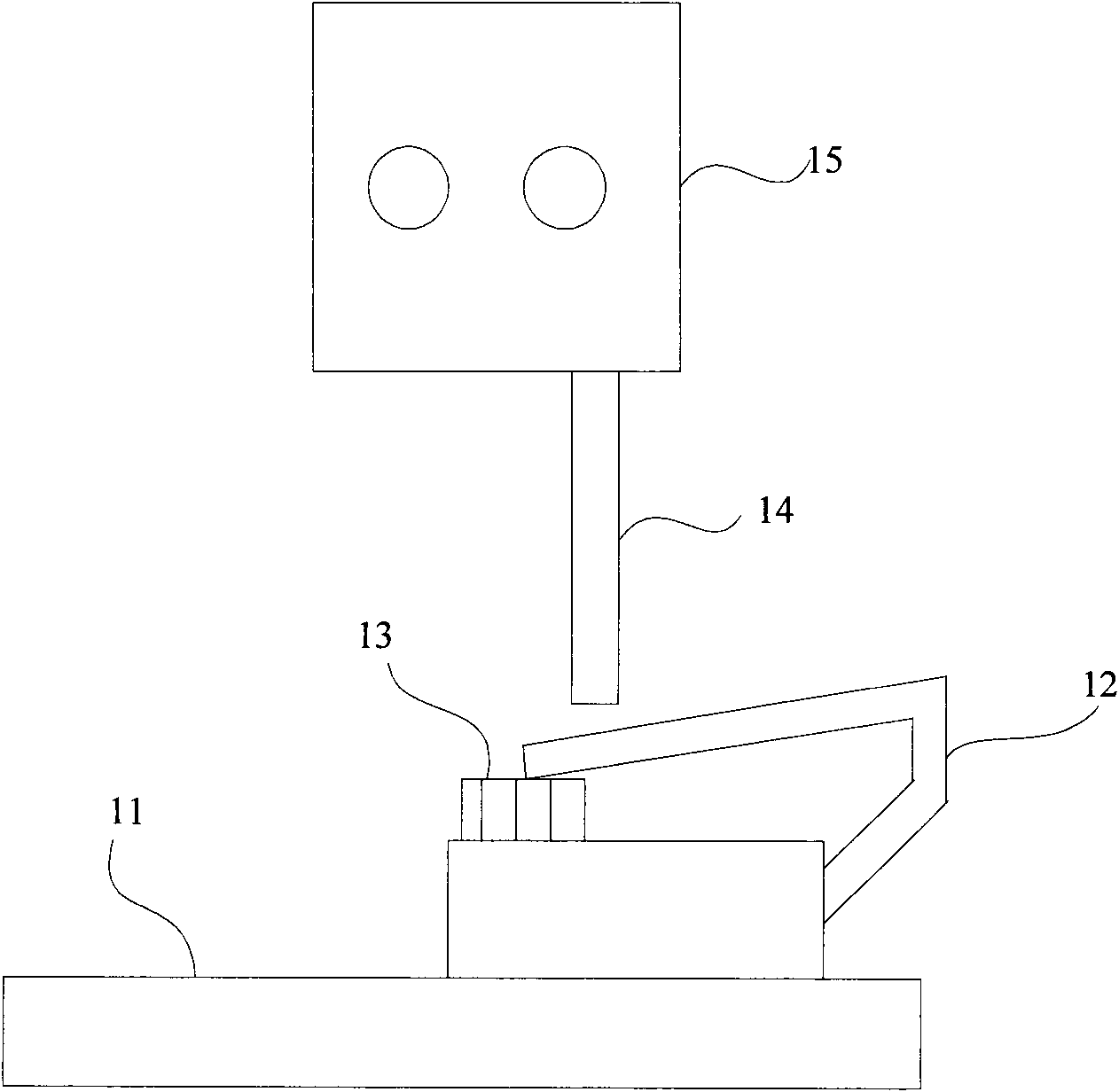

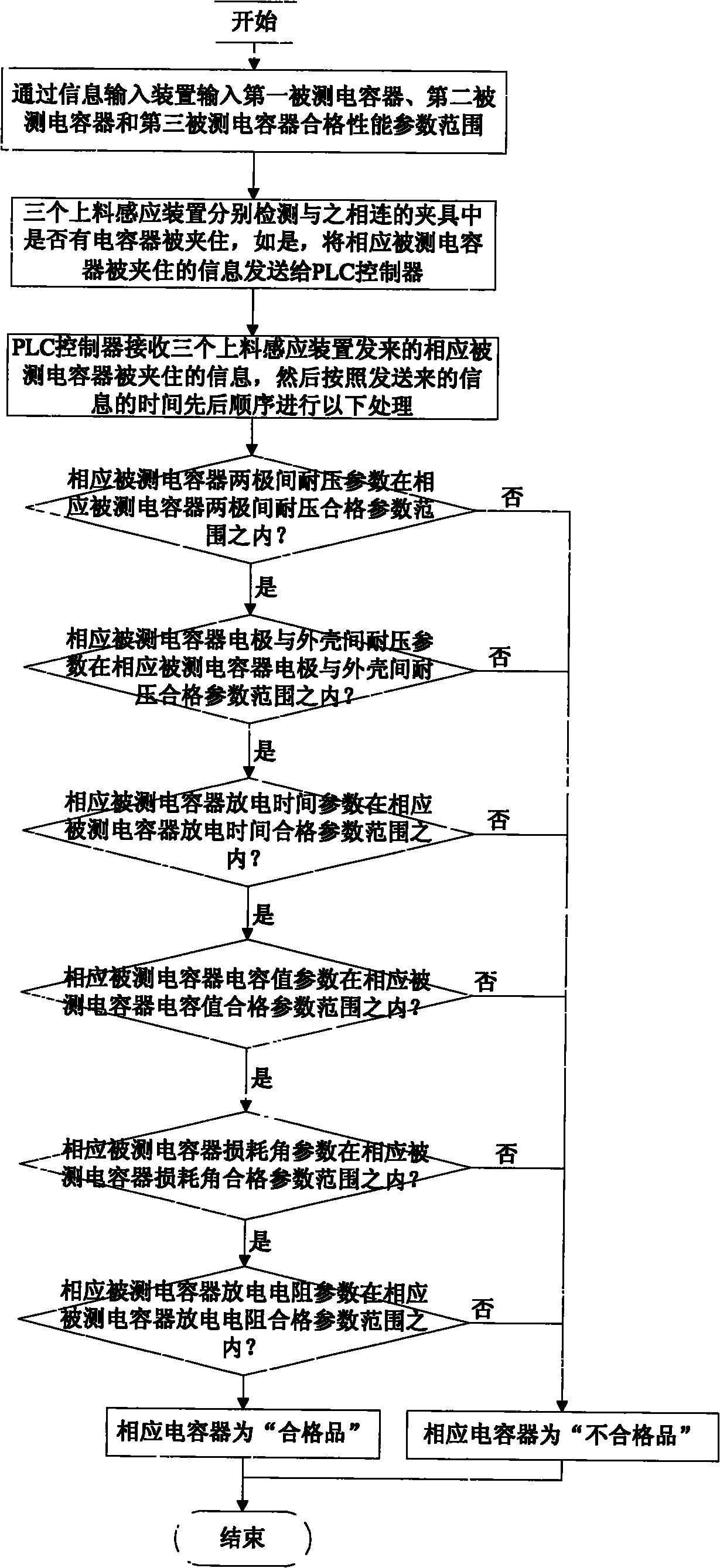

[0050] See figure 1 and figure 2 shown in the detection device of the capacitor, which includes

[0051] The first clamp 1 is used to clamp or release the first capacitor under test;

[0052] The second clamp 2 is used to clamp or release the second capacitor under test;

[0053] The third clamp 3 is used to clamp or release the third capacitor under test;

[0054] The first feeding sensing circuit 4 is connected to the first fixture, and is used to sense whether there is a first measured capacitor connected to the first fixture clip;

[0055] The second feeding sensing circuit 5 is connected to the second fixture, and is used to sense whether there is a second measured capacitor connected to the second fixture clip;

[0056] The third feeding sensing circuit 6 is connected to the third fixture, and is used to sense whether there is a third measured capacitor connected to the third fixture clip;

[0057] The first measured capacitance performance parameter measurement ci...

Embodiment 2

[0086] The difference from Embodiment 1 is that the first measured capacitance performance parameter measurement circuit, the second measured capacitance performance parameter measurement circuit and the third measured capacitance performance parameter measurement circuit are implemented by the same capacitance performance parameter measurement circuit. The capacitance performance parameter measurement circuit has the same structure as the first measured capacitance performance parameter measurement circuit in the first embodiment. Measure the actual performance parameters of the corresponding measured capacitors on the first, second and third fixtures at the same time, and then send the output structure to the automatic controller, see Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com