Magnetic field detection-based synchronous motor static excitation device fault diagnosis method

A synchronous motor, static excitation technology, applied in the field of testing, can solve the problems of burning carbon brush collector ring, bumps or burns, collector ring fire, etc., to ensure normal operation, wide application range and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

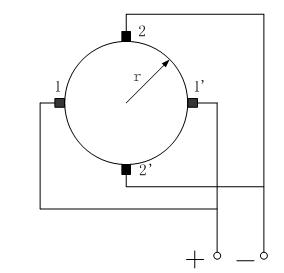

[0018] The most notable feature of the static excitation device fault is the sudden change in the current distribution of the carbon brush caused by the change of the contact impedance between the static carbon brush and the rotating collector ring. This invention takes a relatively simple static excitation device as an example to analyze the static excitation The basic principle of the local magnetic field change of the synchronous motor caused by the device failure, the device principle is as follows figure 1 .

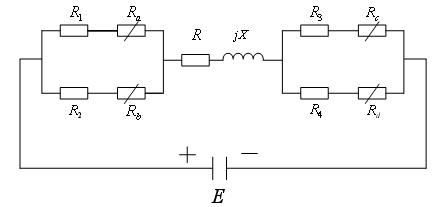

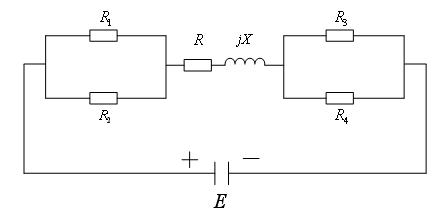

[0019] figure 1 The two carbon brushes 1 and 1' are positive carbon brushes, the two carbon brushes 2 and 2' are negative carbon brushes, and the same pole carbon brushes are spaced apart , Heteropolar carbon brush interval Symmetrical distribution. figure 2 is the equivalent circuit of the excitation system. The collector ring itself is made of copper. Compared with the contact resistance between the carbon brush and the collector ring, the resistance of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com