Parallelized jet loop reactors

A loop reactor and reactor technology, applied in the field of liquid devices, can solve the problems of poor reactor capacity, low material conversion coefficient, high structural cost, etc., and achieve the effect of improving flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

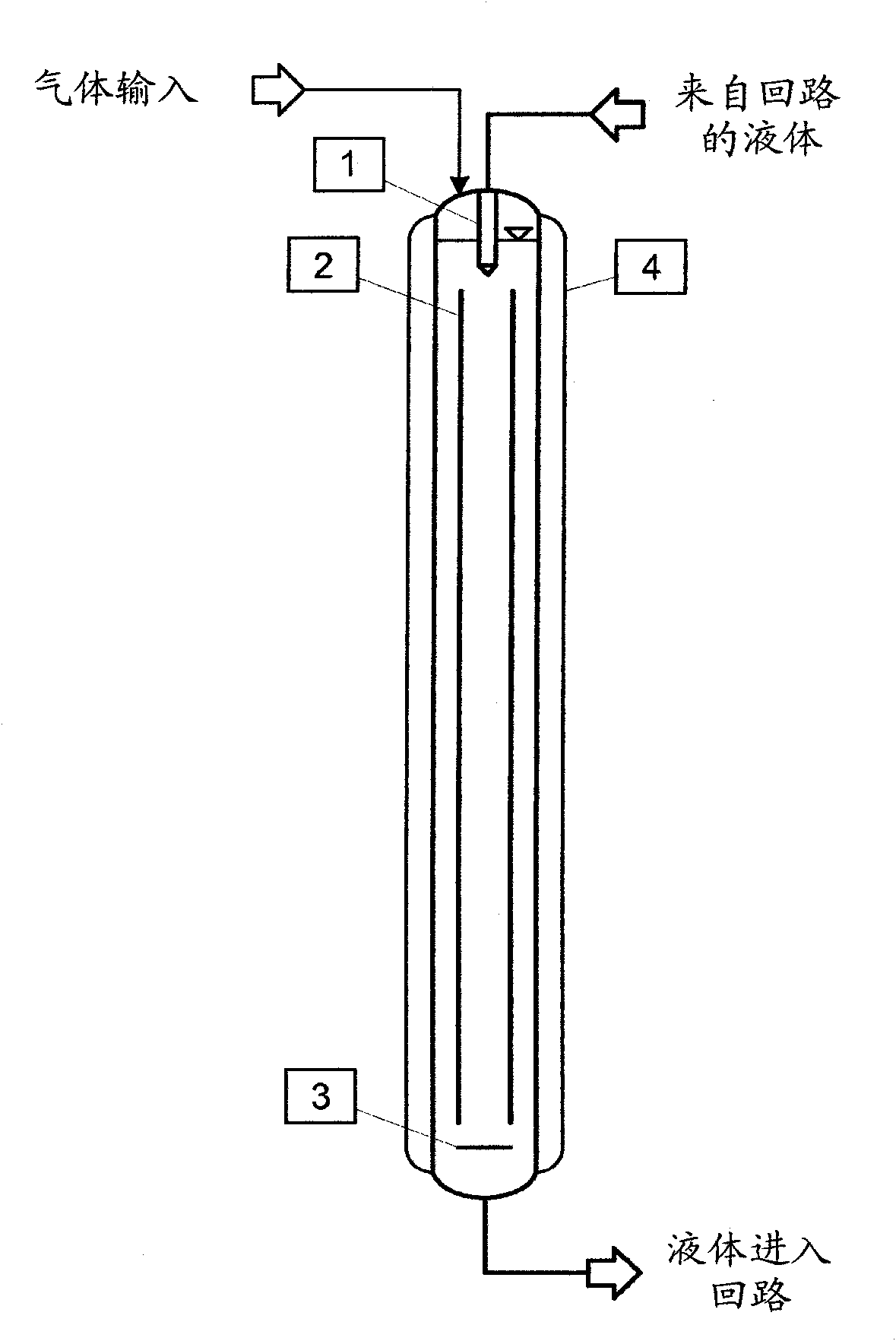

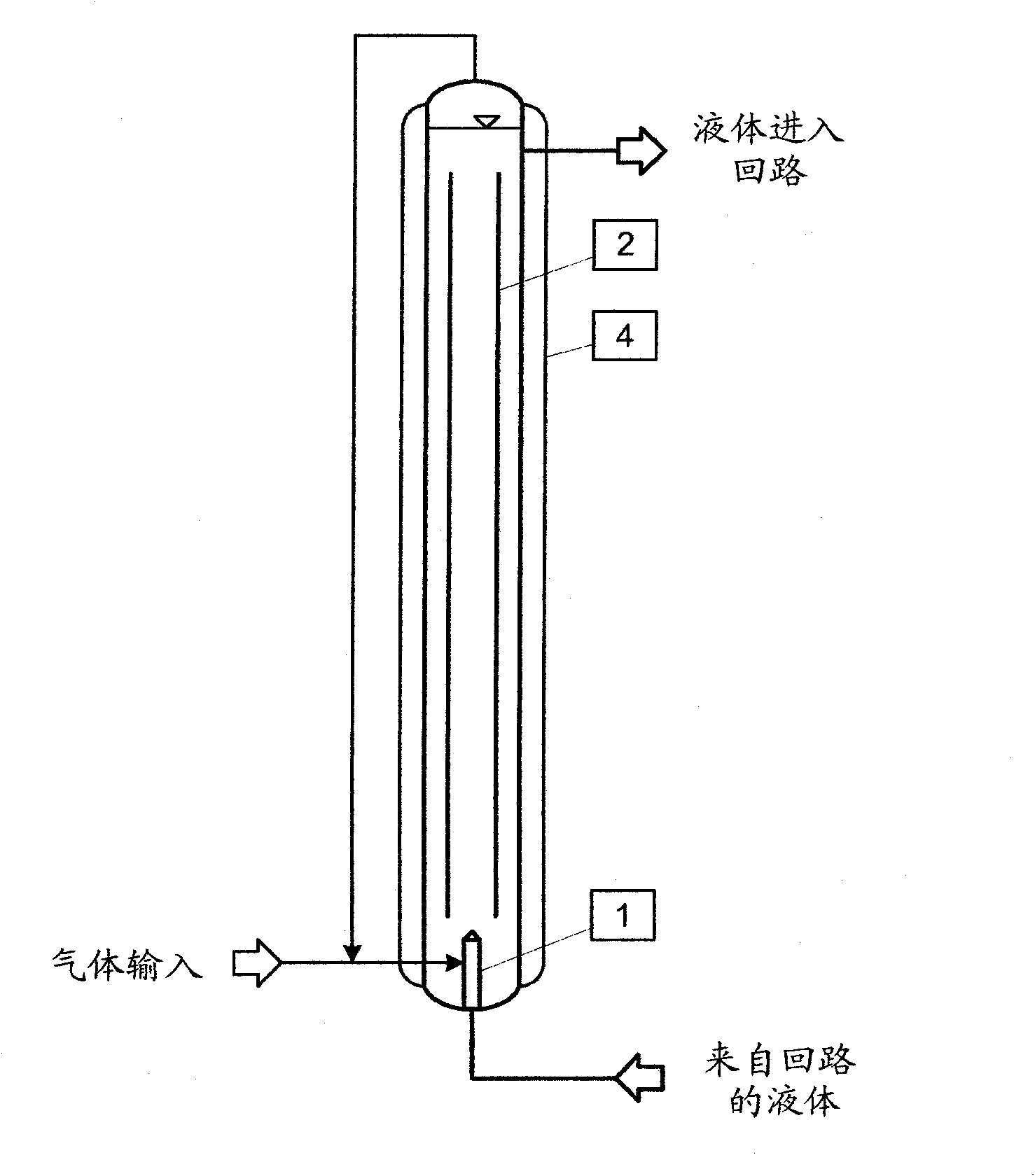

Method used

Image

Examples

example 2

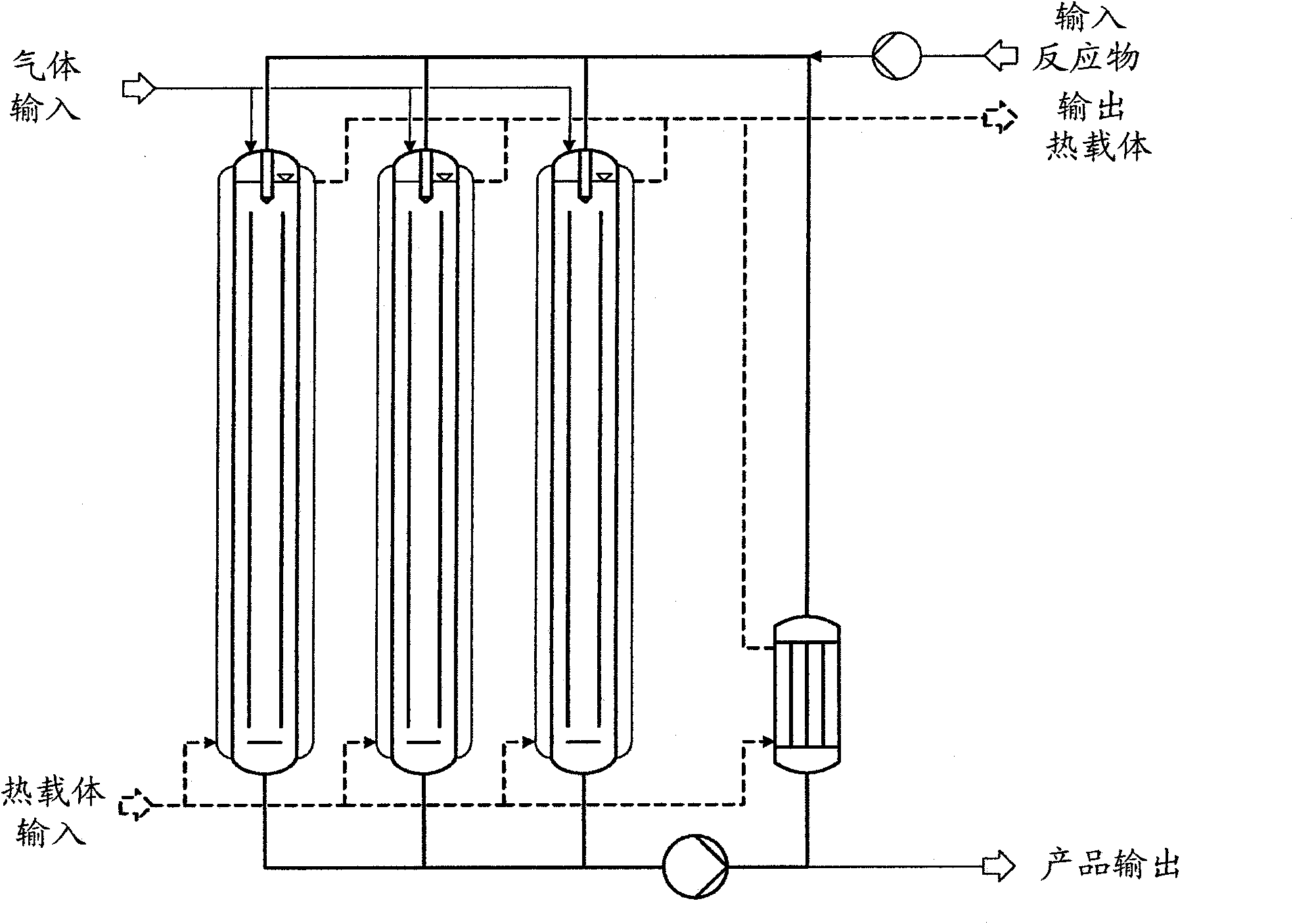

[0062] Example 2 (according to the present invention)

[0063] In accordance with the present invention, according to Figure 4b In the shown setup with two jet loop reactors arranged in parallel, the reactors have an aspect ratio of 10 and a reaction volume of 5 L each, the reaction is carried out corresponding to the reaction conditions described in Example 1. In the device according to the invention complete conversion was achieved after 75 minutes, with an enantiomeric remainder of 95%. Hydrogen pressure can be reduced to 4Mpa, and no obvious by-product formation was observed.

[0064] The examples show that when the reaction according to the invention is carried out in a plant with two parallel jet loop reactors with a slenderness ratio of 10, it is possible to simultaneously reduce the amount of hydrogen compared to a single reactor with a slenderness ratio of 6. When the partial pressure is increased, the reaction speed is obviously improved.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com