Fake nail manufacturing method

A production method and technology for fake nails, applied in the field of fake nails, can solve the problems of polluting the environment, not being environmentally friendly, long, generally two to four hours, and rising labor costs, achieving comfortable and durable wearing, simple mold structure, and arbitrary styles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment: Make false nails according to the following steps:

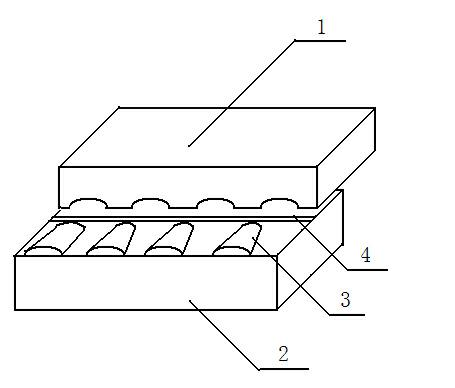

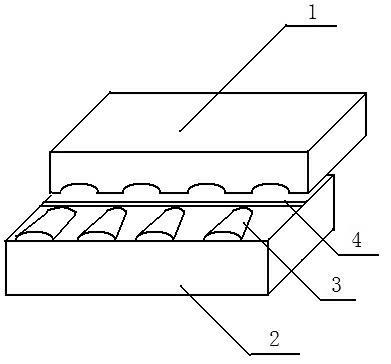

[0017] (1) Make a transparent mold. The mold is composed of an upper mold 1 and a lower mold 2. There are a mold cavity 3 and a flow channel 4 on the mold. The cavity 3 is used for nail forming, and the flow channel 4 is used for extrusion of raw materials;

[0018] (2) Put the liquid false nail raw material into the mold cavity 3 of the lower mold 2, wherein the false nail raw material is composed of the following components according to mass percentage: photosensitive resin Changxing 6145 70%, photoinitiator 819% Fifteen percent, 15 percent of monomer Changxing EM210;

[0019] (3) Close the upper mold 1, apply a pressure of 0.5 to 3 kg to the upper mold 1 and the lower mold 2, and squeeze the excess false nail material in the mold cavity 3 into the runner 4;

[0020] (4) Turn on the ultraviolet light and irradiate the transparent mold with ultraviolet light to promote the curing of the photosensitive ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com