Alkali-resistant high-class ceramic tile sealant

A kind of caulking agent and advanced technology, applied in the field of preparation of advanced ceramic tile caulking agent, which can solve the problems of mildew, white and alkali on tile walls, and tiles falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0007] The specific embodiment of the anti-alkali type high-grade tile grout of the present invention is as follows according to weight percentage:

[0008] PO32.5 cement 35%

[0009] 70-100 mesh washed sand 40.45%

[0010] Secondary fly ash 15%

[0011] 325 mesh heavy calcium powder 5%

[0012] Iron oxide inorganic pigment 2.5%

[0013] Silicone 0.3%

[0014] Superplasticizer 0.2%

[0015] Redispersible latex powder 5044N 0.5%

[0016] Methylcellulose HPMC40000S 0.05%

[0017] MB-P100 antifungal agent 0.5%

[0018] BS32X21133-1 calcium formate 0.5%

[0019] According to the above weight percentage, the dry-mixed mortar mixing equipment is used in the factory to weigh in proportion, mix and stir evenly, and then pack it in barrels to obtain alkali-resistant high-grade tile grout. When using, according to the ratio of dry powder sealant: water = 1: 0.15-0.20, add water and stir evenly before construction and application.

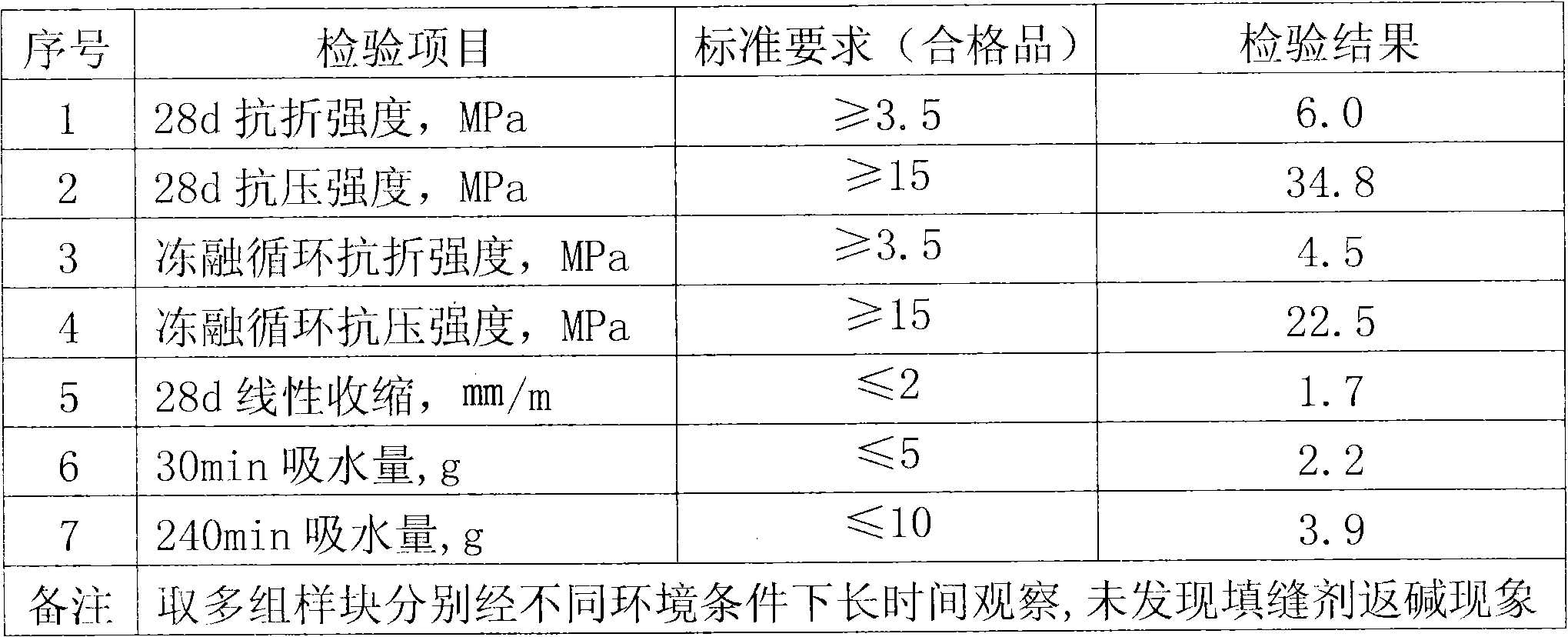

[0020] The technical index of this joint agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com