Bi-component environment-friendly inorganic polymer coating material and preparation method thereof

A technology of inorganic polymers and coating materials, applied in the field of chemical gelling materials, can solve problems such as poor work performance and easy cracking, and achieve the effect of excellent construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

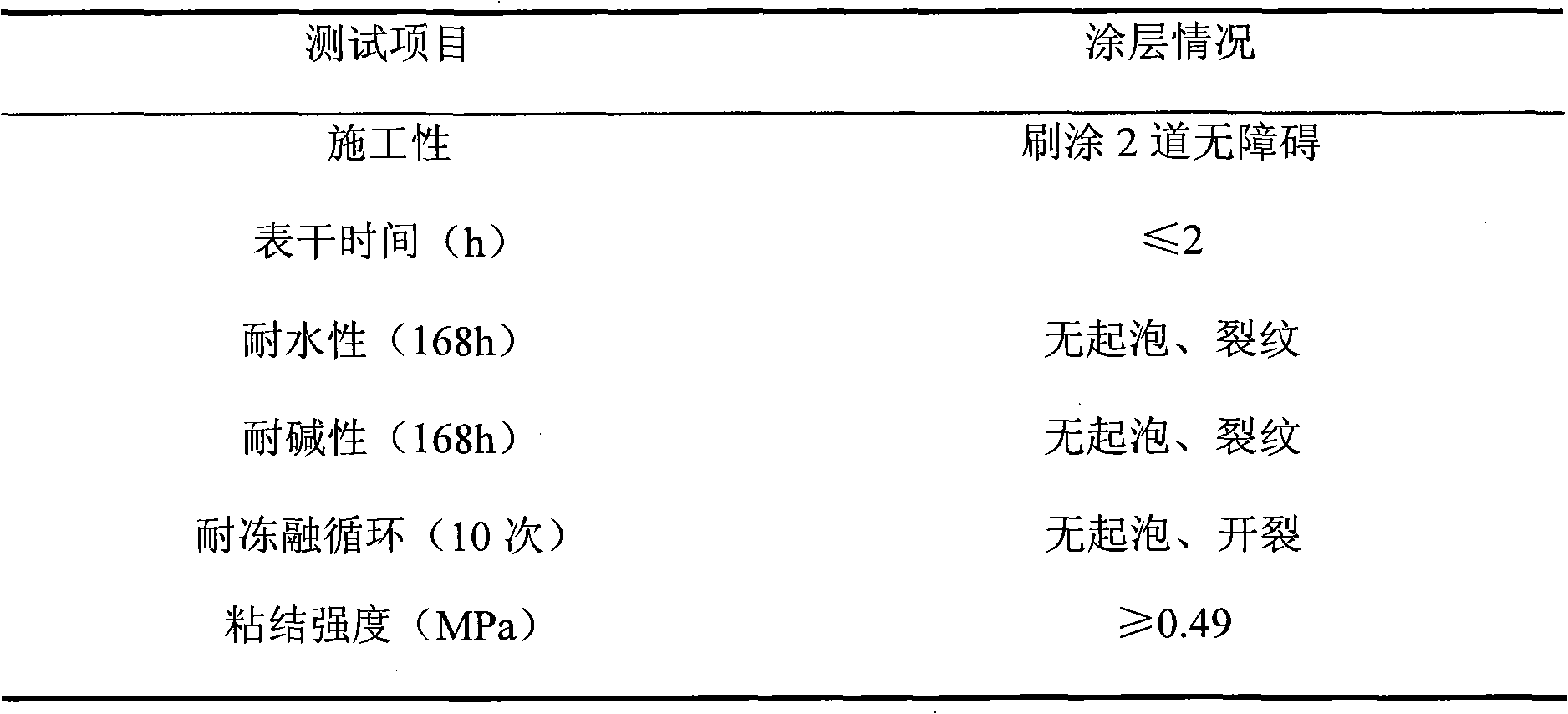

Examples

Embodiment 1

[0024] Weigh the ingredients according to the prescribed formula, and the consumption of each raw material is as follows:

[0025] A component formula:

[0026] Calcined Kaolin 45g

[0027] Sodium Fluosilicate 2g

[0029] Titanium dioxide 5g

[0030] Quartz sand 90g

[0031] Wherein, the particle size range of the powder in the component A formula is: 1-315 μm.

[0032] B component formula:

[0033] Sodium silicate solution (modulus 1.2, mass concentration 38%) 90g

[0034] Bentonite 2g

[0035] Carboxymethylcellulose 1g

[0036] Pour the above-mentioned component B into the cement slurry mixer and slowly stir for 2 minutes, then gradually add component A, and then stir for 3 minutes. After mixing fully, it can be rolled and sprayed without adding water to form a thick texture. Sand wall coating.

Embodiment 2

[0038] Weigh the ingredients according to the prescribed formula, and the consumption of each raw material is as follows:

[0039] A component formula:

[0040] Calcined Kaolin 50g

[0041] Mica powder 5g

[0042] Titanium dioxide 5g

[0043] Talc powder 5g

[0044] Quartz sand 100g

[0045] Wherein, the particle size range of the powder in the component A formula is: 1-315 μm.

[0046] B component formula:

[0047] Sodium silicate solution (modulus 1.2, mass concentration 40%) 90g

[0048] Bentonite 2g

[0049] Carboxymethylcellulose 1g

[0050]Pour the above-mentioned component B into the cement slurry mixer and slowly stir for 2 minutes, then gradually add component A, and then stir for 3 minutes. After mixing fully, it can be rolled and sprayed without adding water to form a thick texture. Sand wall coating.

Embodiment 3

[0052] Weigh the ingredients according to the prescribed formula, and the consumption of each raw material is as follows:

[0053] A component formula:

[0054] Calcined Kaolin 45g

[0055] Sodium Fluosilicate 1g

[0056] Mica powder 10g

[0057] Iron oxide red 2g

[0058] Talc powder 5g

[0059] Marble powder 90g

[0060] Wherein, the particle size range of the powder in the component A formula is: 1-315 μm.

[0061] B component formula:

[0062] Sodium silicate solution (modulus 1.2, mass concentration 35%) 85g

[0063] Bentonite 1g

[0064] Carboxymethylcellulose 2g

[0065] Pour the above-mentioned component B into the cement slurry mixer and slowly stir for 2 minutes, then gradually add component A, and then stir for 3 minutes. After mixing fully, it can be rolled and sprayed without adding water to form a thick texture. Sand wall coating.

[0066] 2. Thin layer coating material

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com