Titanium-based nickel buckle stripper

A nickel button seed plate and titanium-based technology, applied in the field of electrolytic nickel production, can solve the problems of corrosion, growth column shedding, easy to fall off, etc., and achieve the effects of reducing production cost, prolonging service life and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Attached below figure 1 An embodiment of the present invention is described.

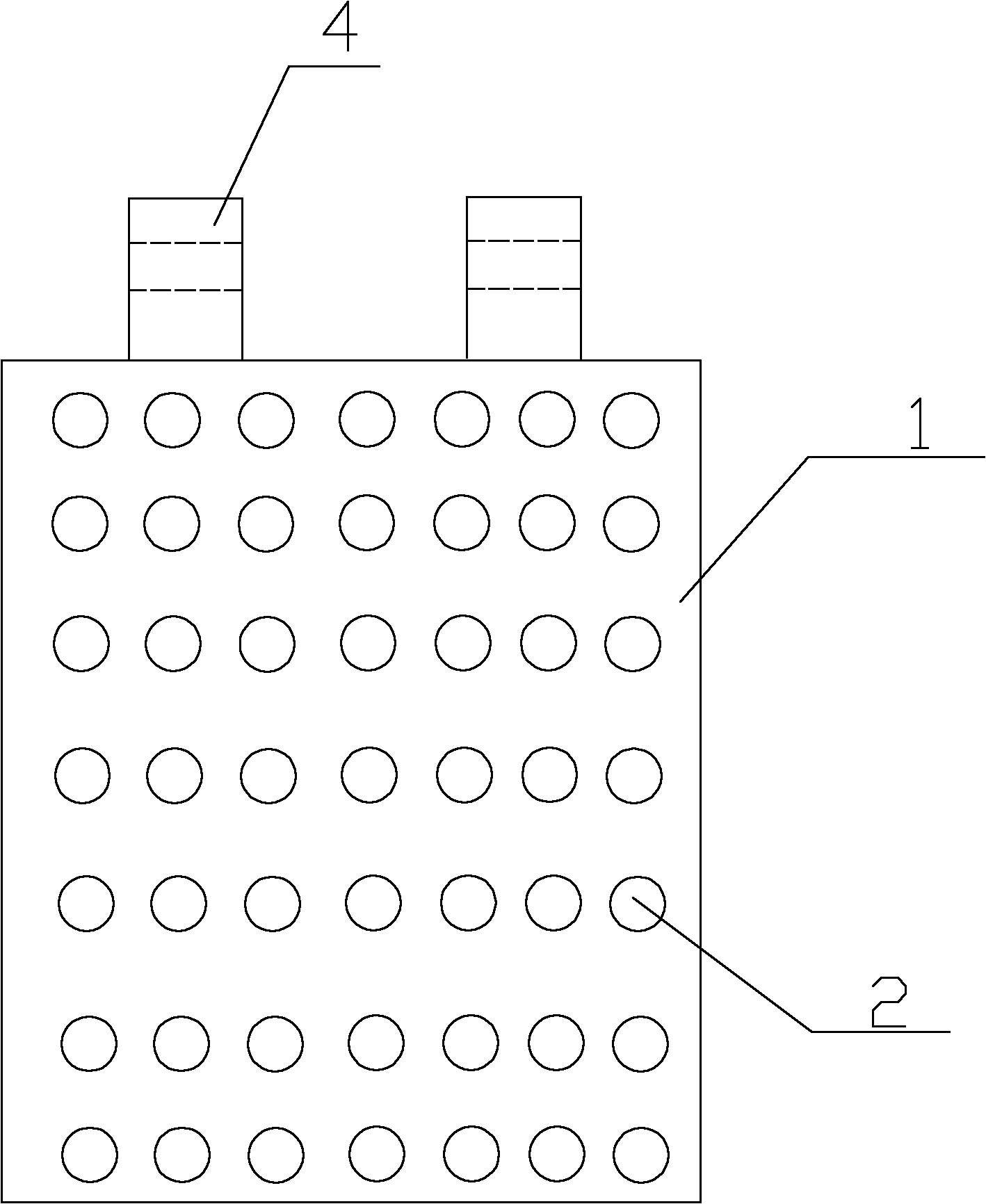

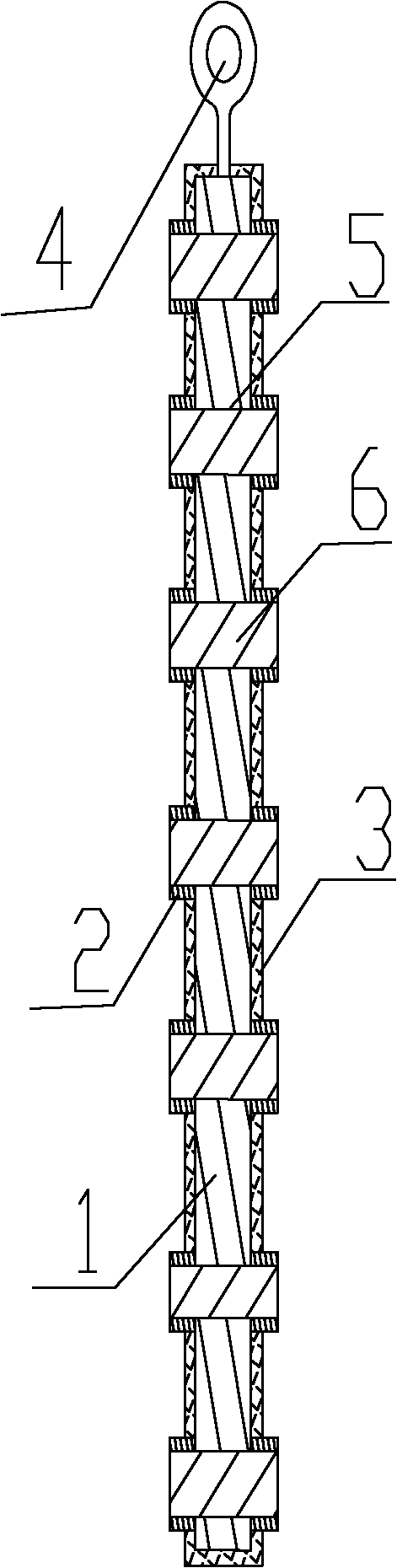

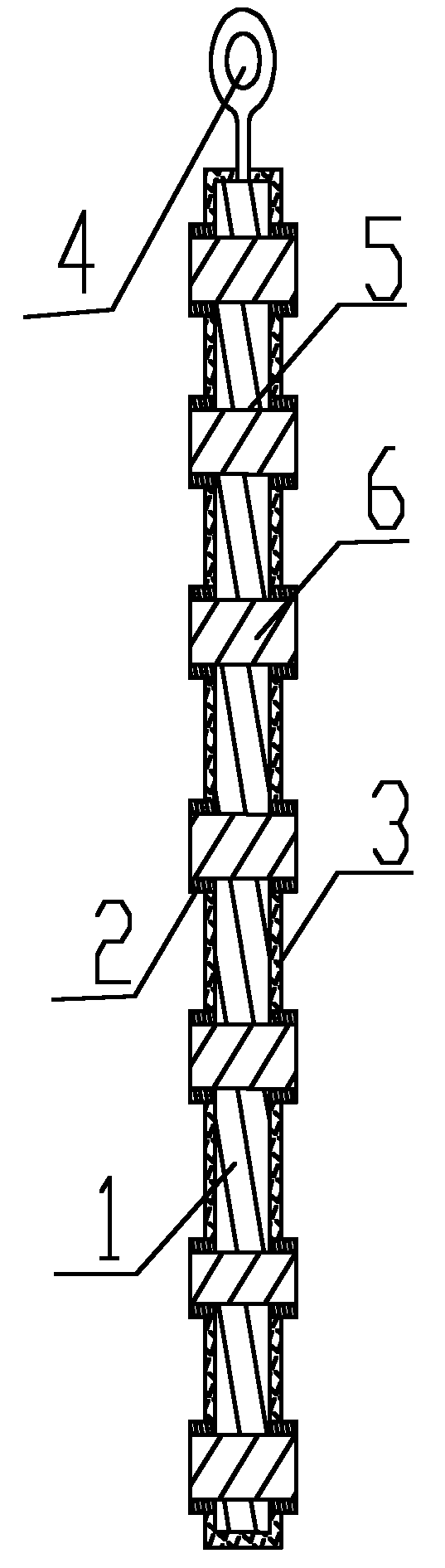

[0016] A titanium-based nickel buckle plate, which has a titanium base plate 1, the uppermost end of the titanium base plate 1 is provided with an ear plate 4, and through holes 5 are evenly distributed on the titanium base plate 1, and conductive posts 6 are fixed on the through holes 5 through interference fit , and the conductive pillars 6 extend to both sides of the titanium substrate 1 with equal lengths. The growth column 2 has a ring-shaped structure, which is fitted and fixed on the end of the conductive column 6 by welding. The surface of the titanium substrate 1 and the side wall of the growth column 2 are coated with a silicon rubber insulating layer 3 by a fluidized bed process, and the thickness of the insulating layer 3 is 1.5-2.5mm.

[0017] The insulating layer 3 isolates the titanium substrate 1 from the outside, and at the same time, the outer end surfaces of the growth co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com