Motor clutching flywheel of industrial sewing machine and manufacturing method thereof

An industrial sewing machine and flywheel technology, applied in the field of industrial sewing machines, can solve the problems of uneven quality of flywheel circumference, unstable material hardness, uneven balance, etc., and achieve the effects of good balance, low manufacturing cost and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

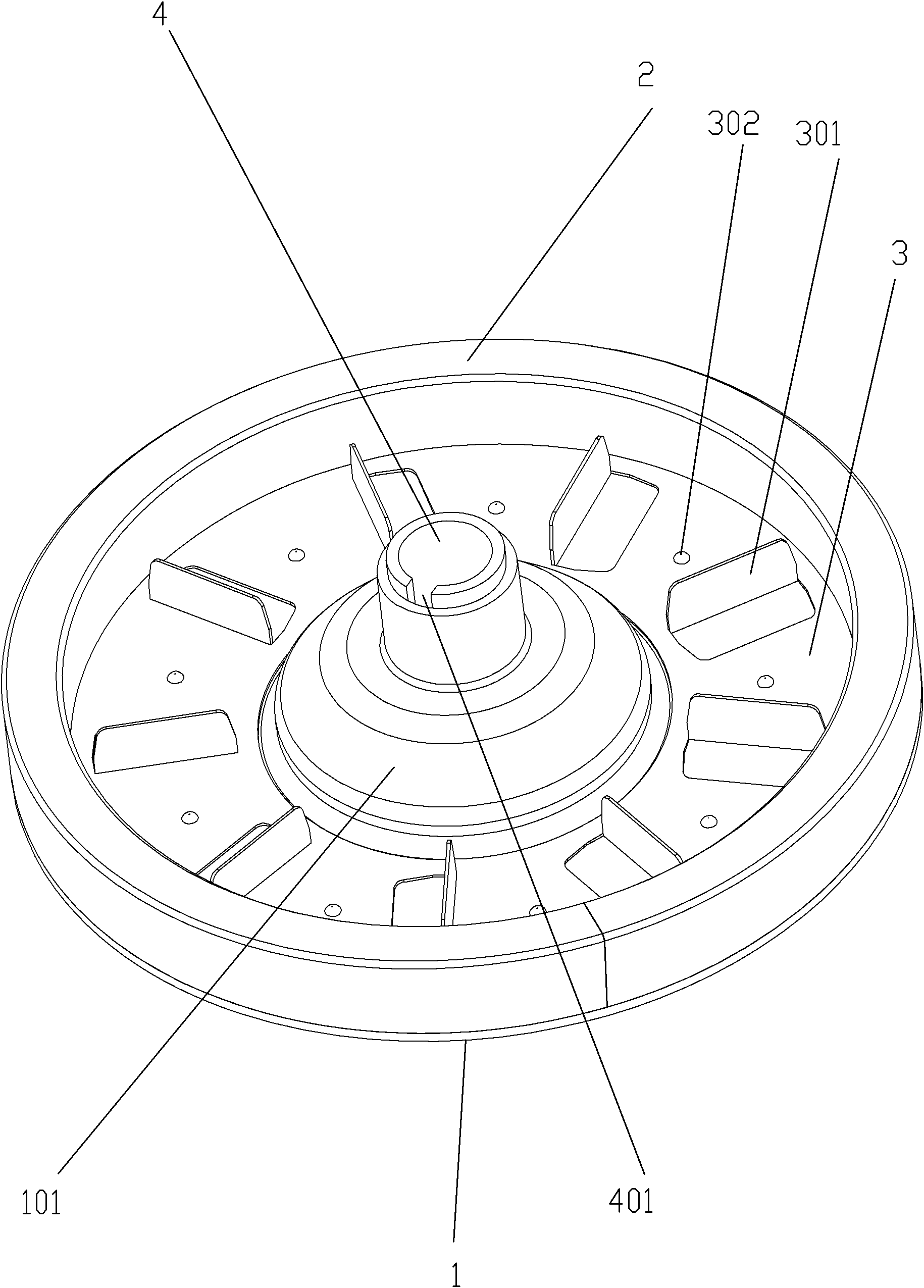

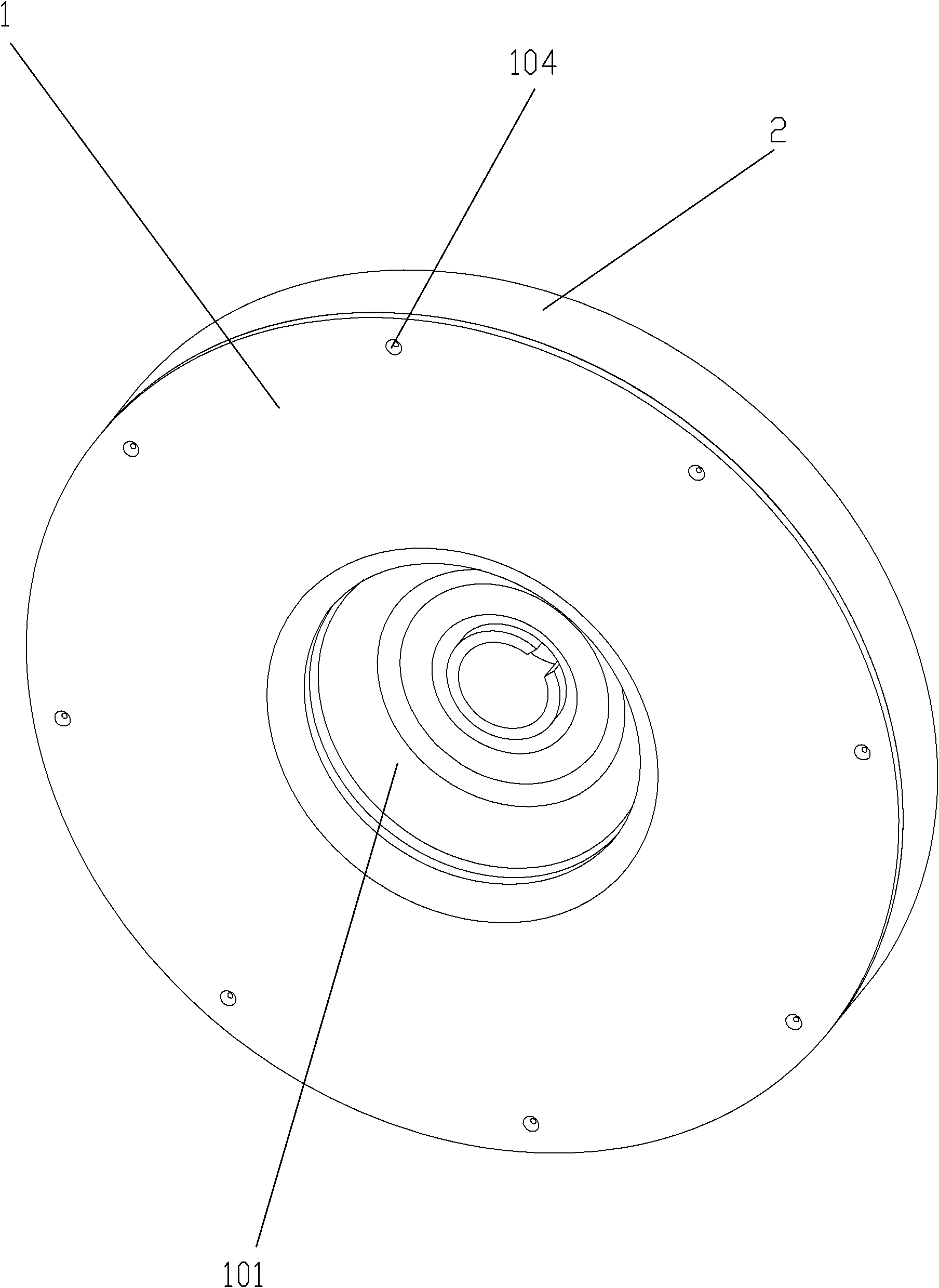

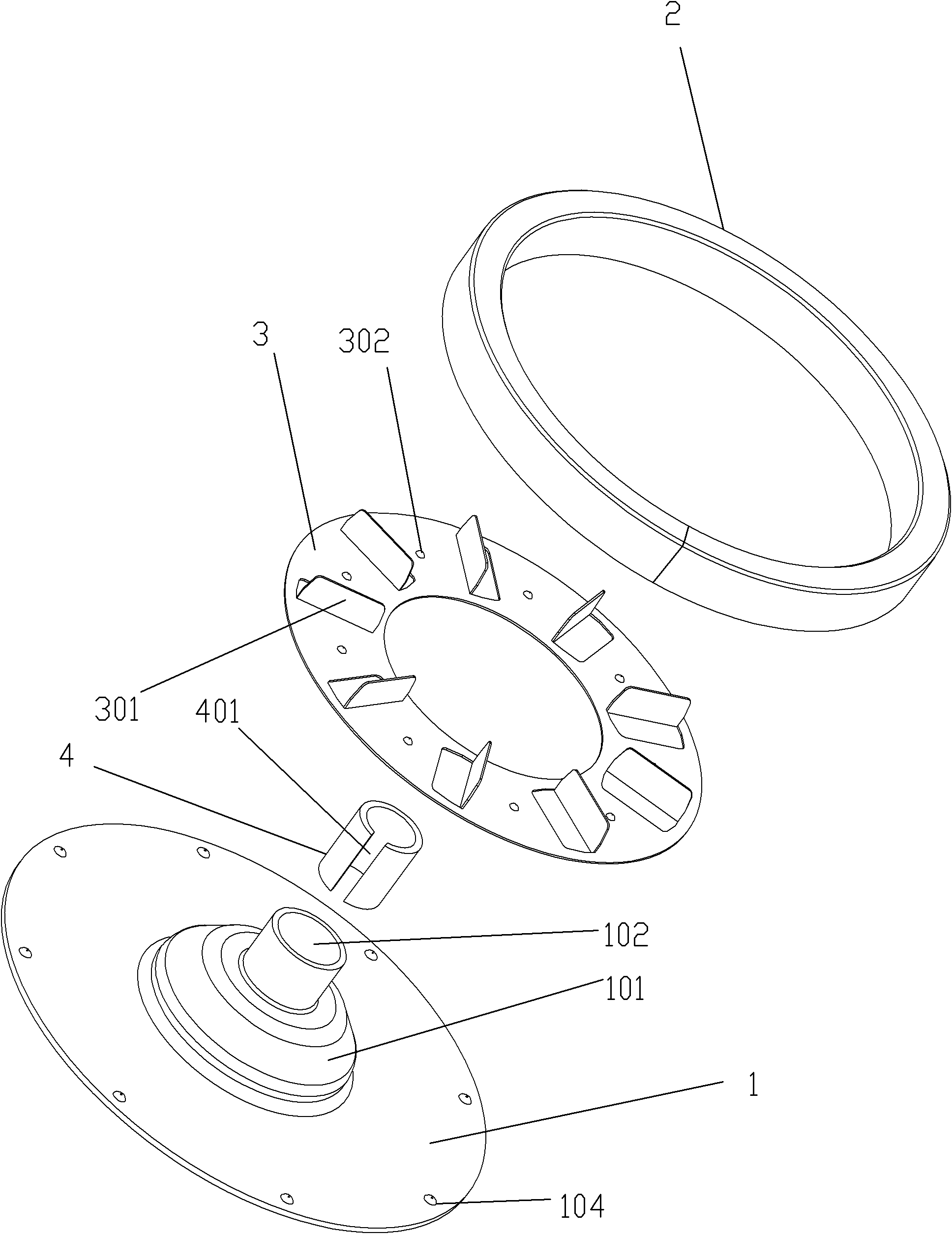

[0028] An industrial sewing machine motor clutch flywheel, including a stamped flywheel plate 1, the flywheel plate 1 is provided with a rearwardly protruding coupling portion 101, and a flywheel is fixedly connected to the rear side of the flywheel plate 1 Ring 2, the flywheel ring 2 is provided with an impeller 3 closely connected to the flywheel plate 1.

[0029] The coupling part 101 is provided with a coupling hole 102, and the flywheel collar 4 is installed in the coupling hole 102.

[0030] The outline of the flywheel plate 1 is circular, and the flywheel ring 2 is made of bent square steel.

[0031] The flywheel ring 2 is welded on the outer edge of the flywheel plate 1 .

[0032] The flywheel neck sleeve 4 is a round tube with an axially extending slit 401 on one side.

[0033] The rear side of the impeller 3 is provided with vanes 301 formed by punching and folding the impeller body.

[0034] The flywheel plate 1 is provided with a front welding pit 104 , and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com