Image type spinneret plate automatic detector

A spinneret and detector technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of fully automatic detection without in-depth discussion, and achieve reduced workload, good objectivity and consistency, and detection efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

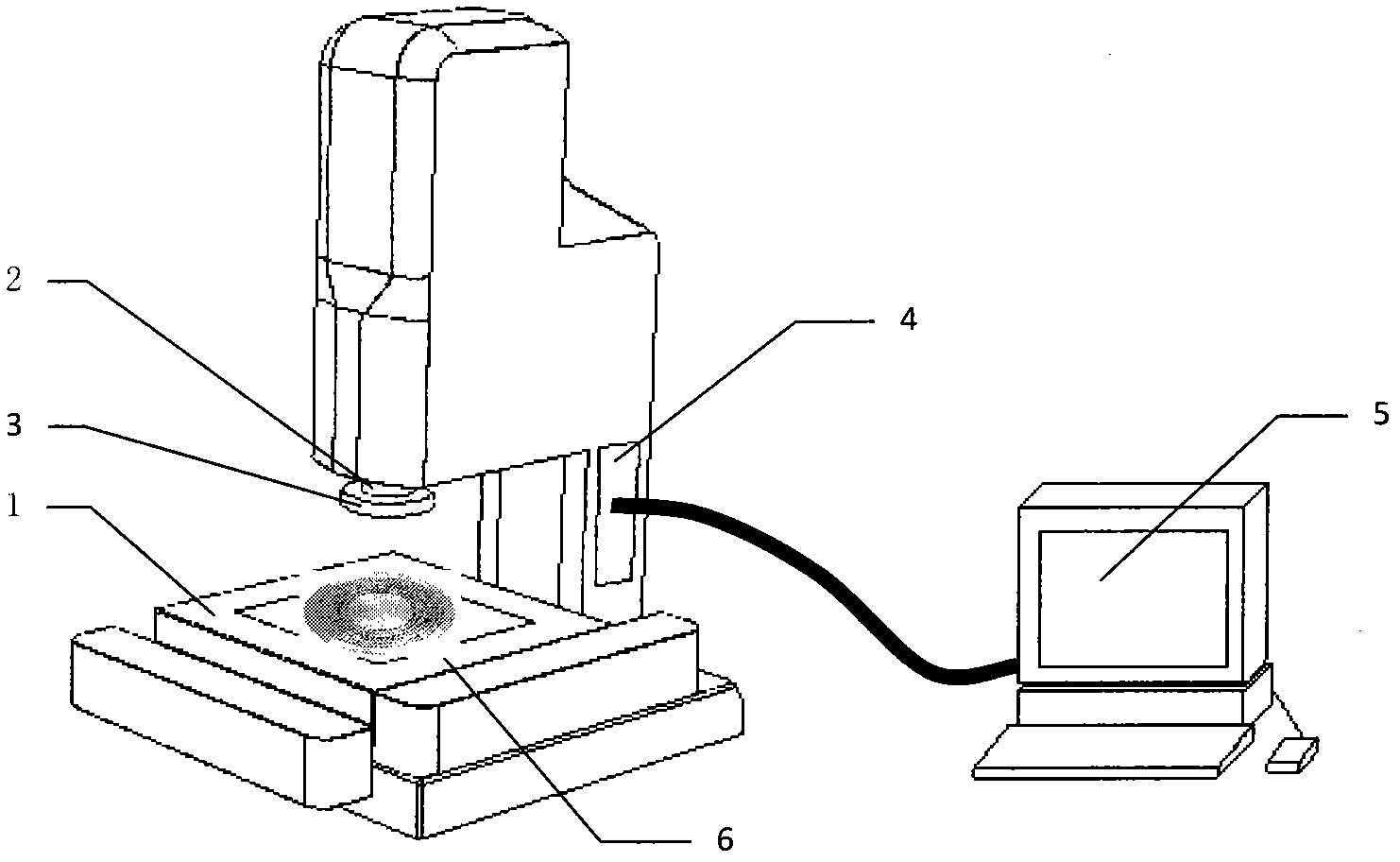

[0019] The three-axis mobile working platform includes three independent movement axes of XYZ. The table and base of the movement axes are made of granite. Each axis is carried by a guide rail and driven by a ball screw. Driven by a DC servo motor, the encoder feeds back the motor speed, and the grating scale feeds back the platform position, thus forming a fully closed-loop system. The use of high-precision linear guides and high-resolution grating scales, relying on fine adjustments, can ensure that the entire three-axis mobile working platform achieves high precision and repeatability.

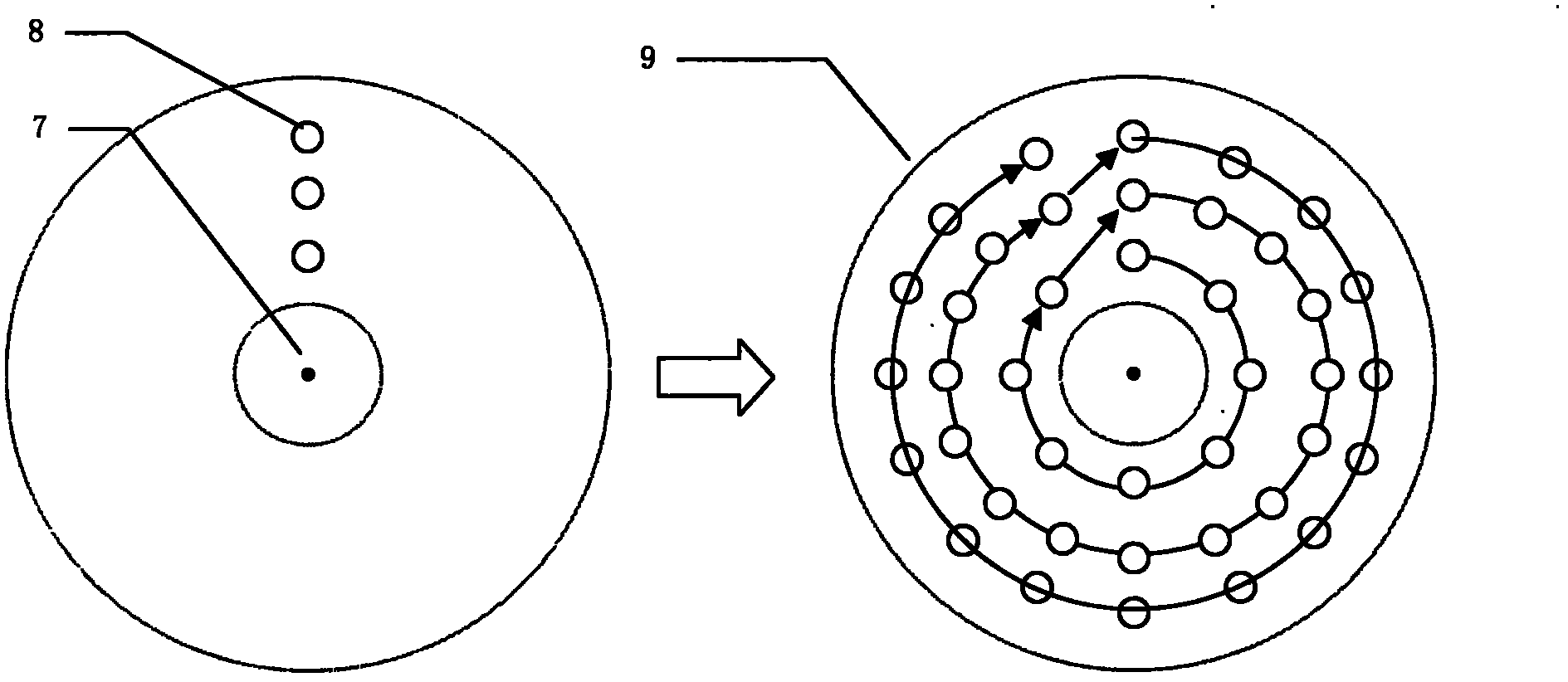

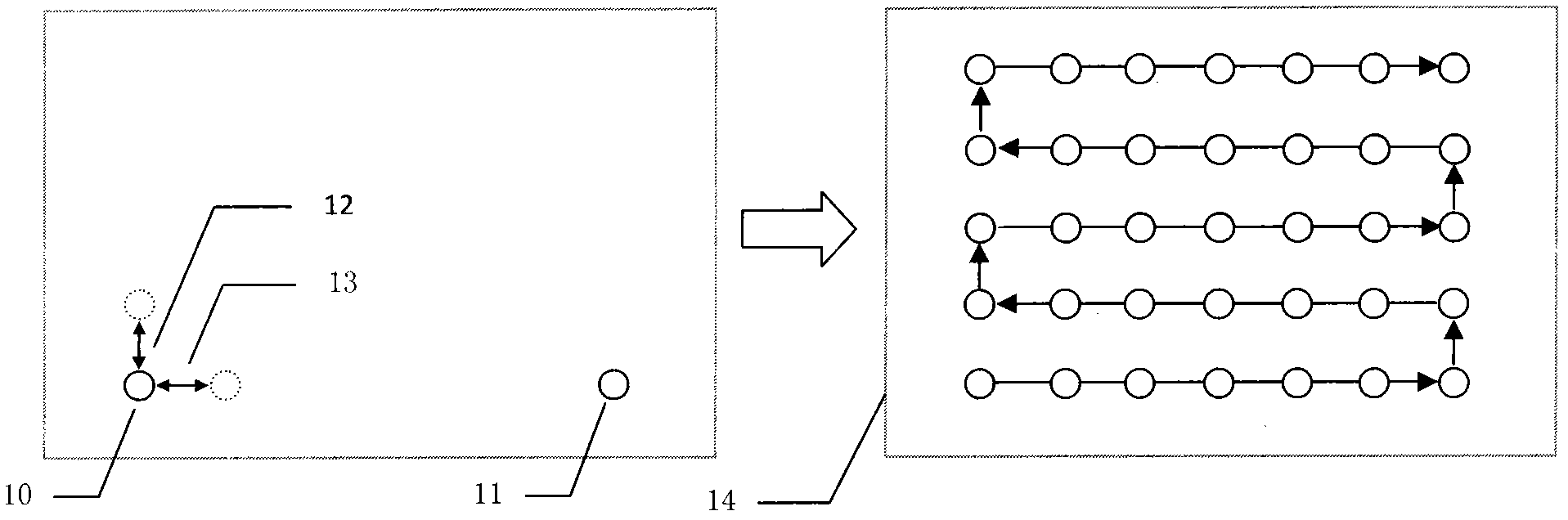

[0020] The personal computer controls the movement of the XY axis through the motion controller and the driver, and can move the areas to be measured of the spinneret into the field of view of the microscope one by one, and complete the scanning of the spinneret in sequence. If necessary, the Z-axis movement can also be controlled to realize automatic focusing on the detection spinneret hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com