Projection centrifugal automatic rotation spraying device

An automatic rotating and spraying device technology, which is applied in fire rescue and other directions, can solve the problems of rotary spraying failure, unreasonable setting of rotating mechanism, and affecting fire extinguishing effect, etc., to reduce engineering cost, easy to install and fix, and to overcome the easy corrosion of bearings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

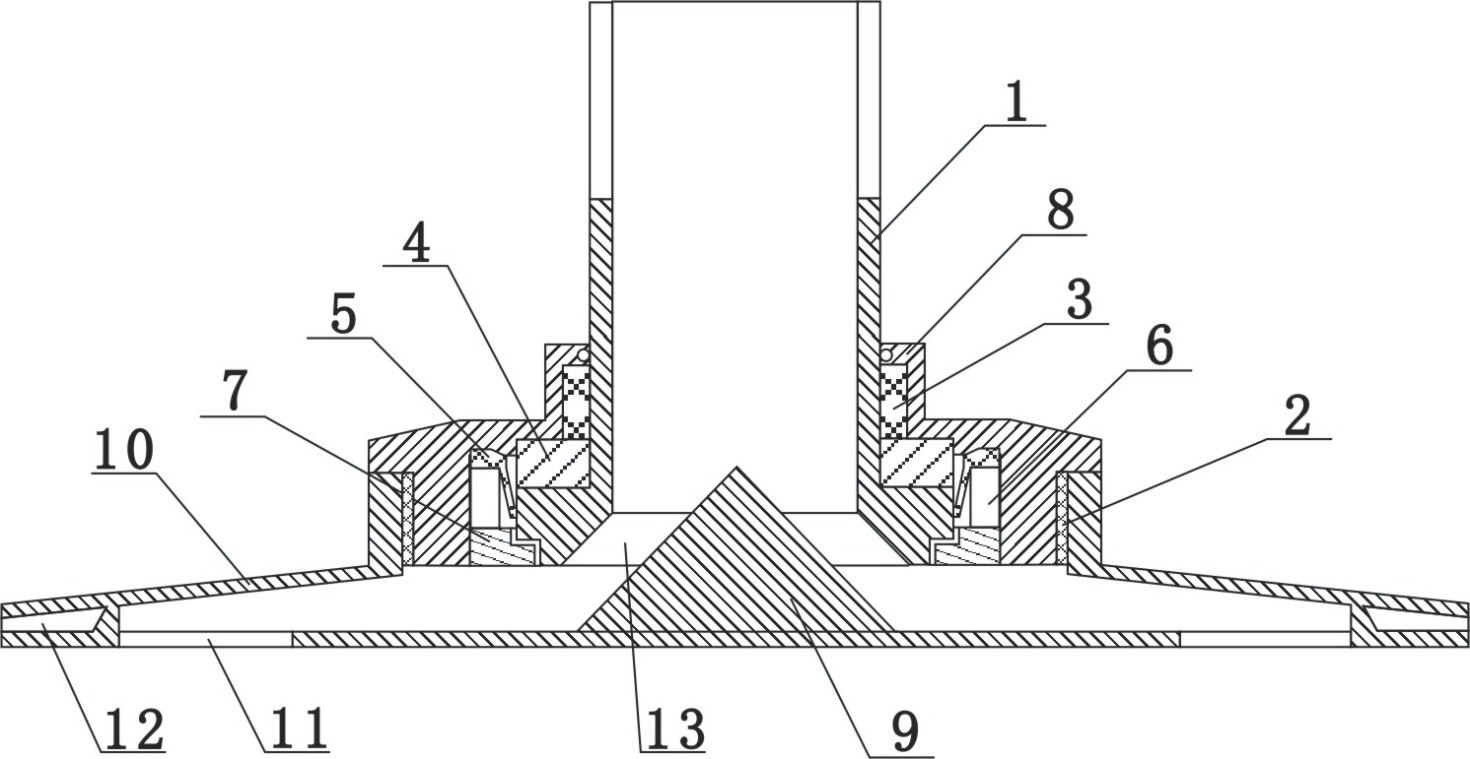

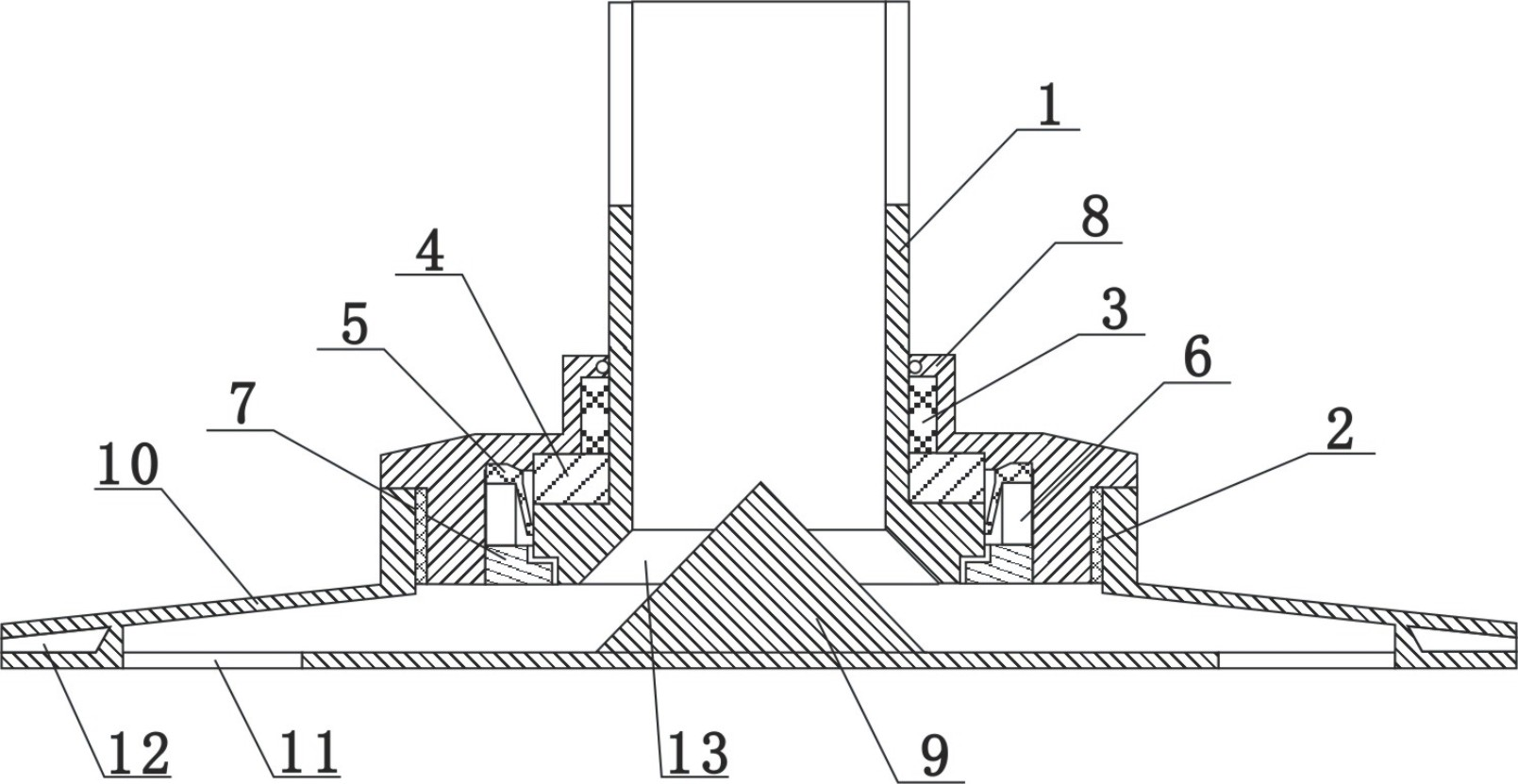

[0016] The present invention will be further described below in conjunction with accompanying drawing.

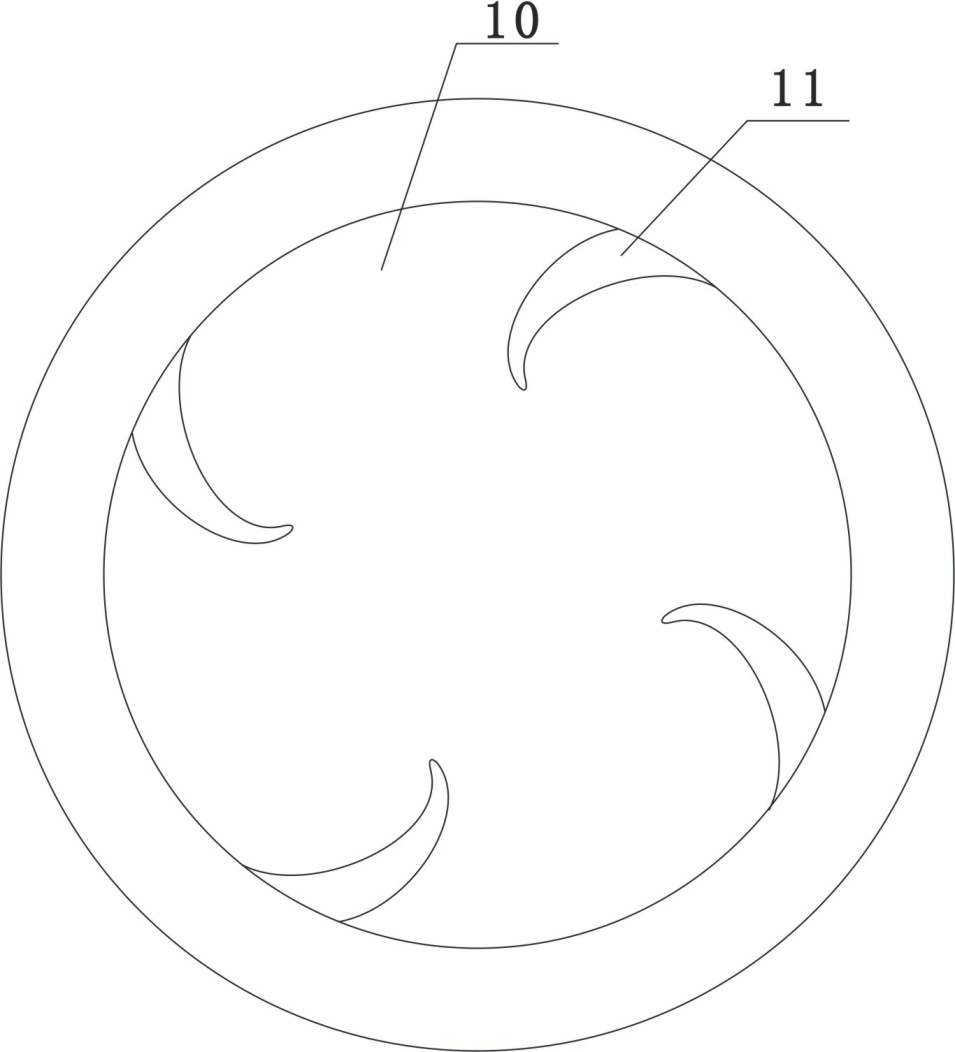

[0017] see figure 1 and figure 2 , the projectile centrifugal automatic rotary spraying device of the present invention comprises a liquid inlet standpipe body 1 with an overflow channel 13, an upper end cover 8, a lower end cover 10 and a conical flow control tongue 9, and the flow control tongue 9 is arranged on the lower end cover 10 In the middle part of the upper surface, the liquid inlet riser body 1 is a stepped connecting pipe, and an oil-free end bearing 4 and an oil-free axial bearing 3 are sequentially sleeved on the liquid inlet riser body 1, and the upper end cover 8 It is sleeved on the outside of the oil-free axial surface bearing 3 and the oil-free end surface bearing 4, and there is a gap between the oil-free end surface bearing 4, and a spigot shaft surface seal 5 and a spigot shaft surface seal 5 are arranged in the gap The lower end cover 10 is screwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com