Bevel gear shaft tooth surface pitch cone locating tool

A technology for positioning tooling and axles, which is applied in the direction of gear teeth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve problems such as shock vibration, low coaxiality accuracy, noise, etc., to prevent the ring gear from beating and improve The effect of product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

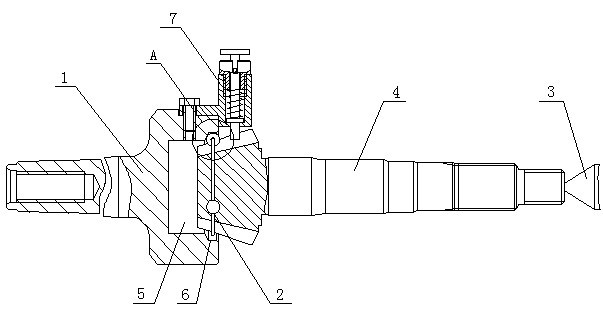

[0019] Embodiment 1: as figure 1 As shown, a bevel gear shaft tooth surface pitch cone positioning tool includes a tooling body 1 with a Morse taper handle, a floating steel ball retaining ring 2, a top 3 and a fast telescopic anti-rotation pin assembly 7. The floating steel ball The ball retaining ring 2 is set in the tooth groove at the front end of the processed product 4 and placed in the groove 5 provided at the right end of the tooling body 1 with a Morse taper shank, and the floating steel ball retaining ring 2 abuts against the groove. There are 6 limiting steps in the groove 5, the top 3 is against the center hole of the tail end of the processed product 4, and the product is held and rotated about 90 degrees to 135 degrees around the axis, so that the product is automatically centered and installed. Finish.

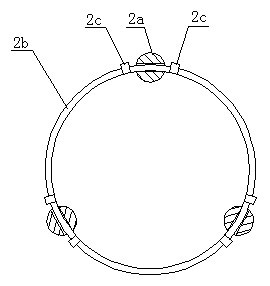

[0020] Such as figure 2 As shown, the floating steel ball retaining ring 2 includes three steel balls with holes 2a, steel wires 2b and limit stops 2c, the t...

Embodiment 2

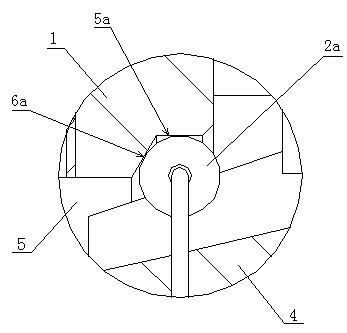

[0023] Embodiment 2: as Figure 5 with 6 As shown, wherein the floating steel ball retaining ring 2 includes four steel balls with holes 2a, steel wires 2b and limit stops 2c, the four steel balls with holes 2a are evenly distributed on the circumference of the steel wires 2b, and the steel balls with holes The aperture of 2a is larger than the diameter of the steel wire 2b, and the limit stoppers 2c are respectively arranged on the steel wire 2b and on both sides of the corresponding steel balls with holes 2a, and there is a certain distance between the limit stoppers 2c and the corresponding steel balls with holes 2a. spacing; as Figure 7 As shown, the perforated steel ball 2a abuts against the groove inner wall 5a and the limit step wall 6a at the limit step 6 respectively, the groove inner wall 5a and the limit step wall 6a form a right angle structure, and the limit step Point supports are formed on the steel balls with holes in the axial and radial directions to meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com