Unstressed installation method for solar cell array driving mechanism

A technology of solar cell array and driving mechanism, which is applied in the direction of power supply system of space navigation vehicle, etc., achieves the effect of wide application prospect, feasible operation and reasonable method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

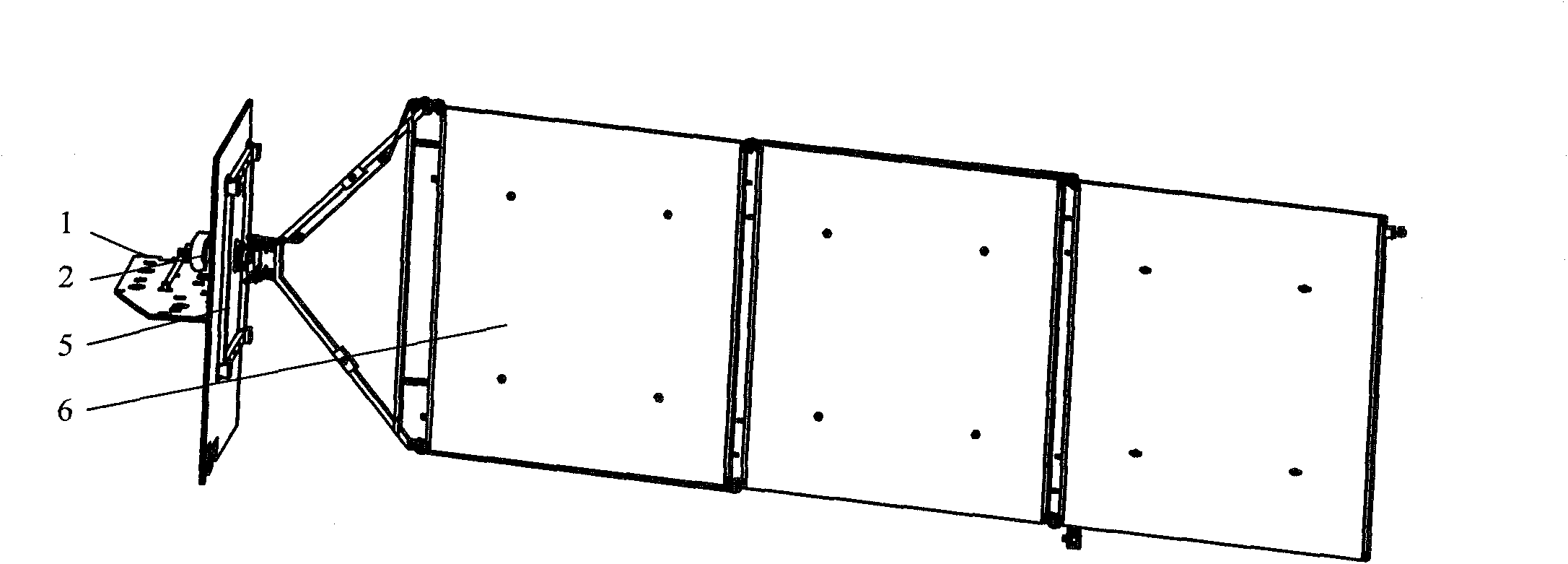

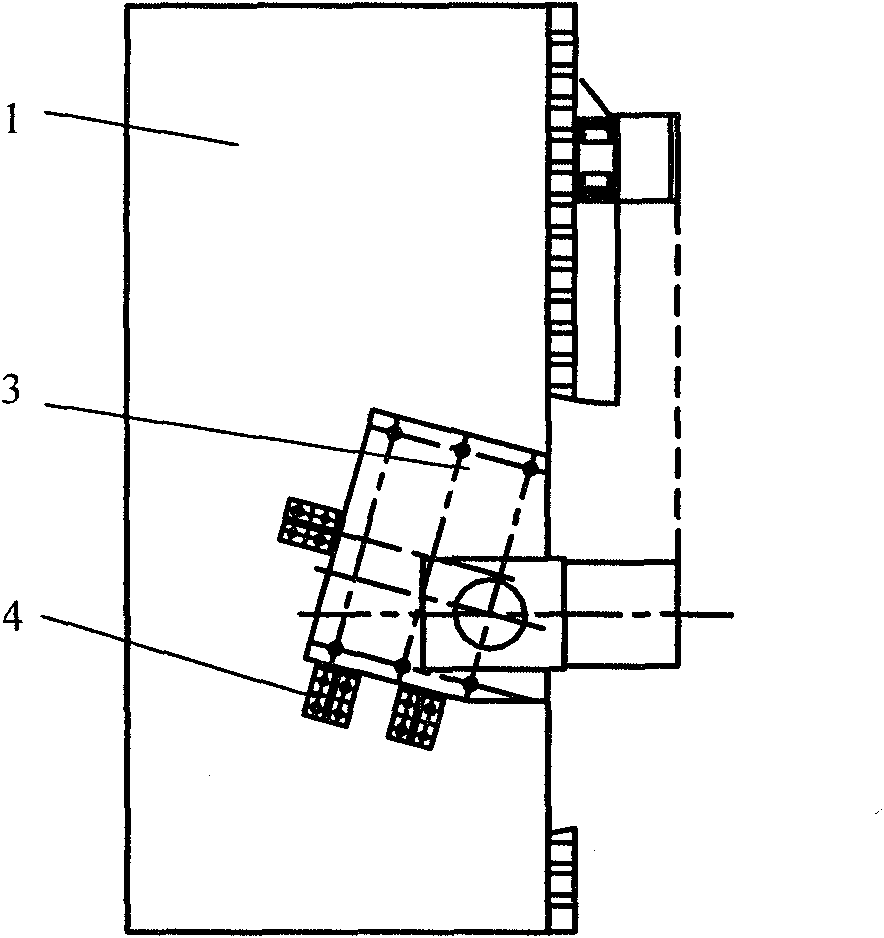

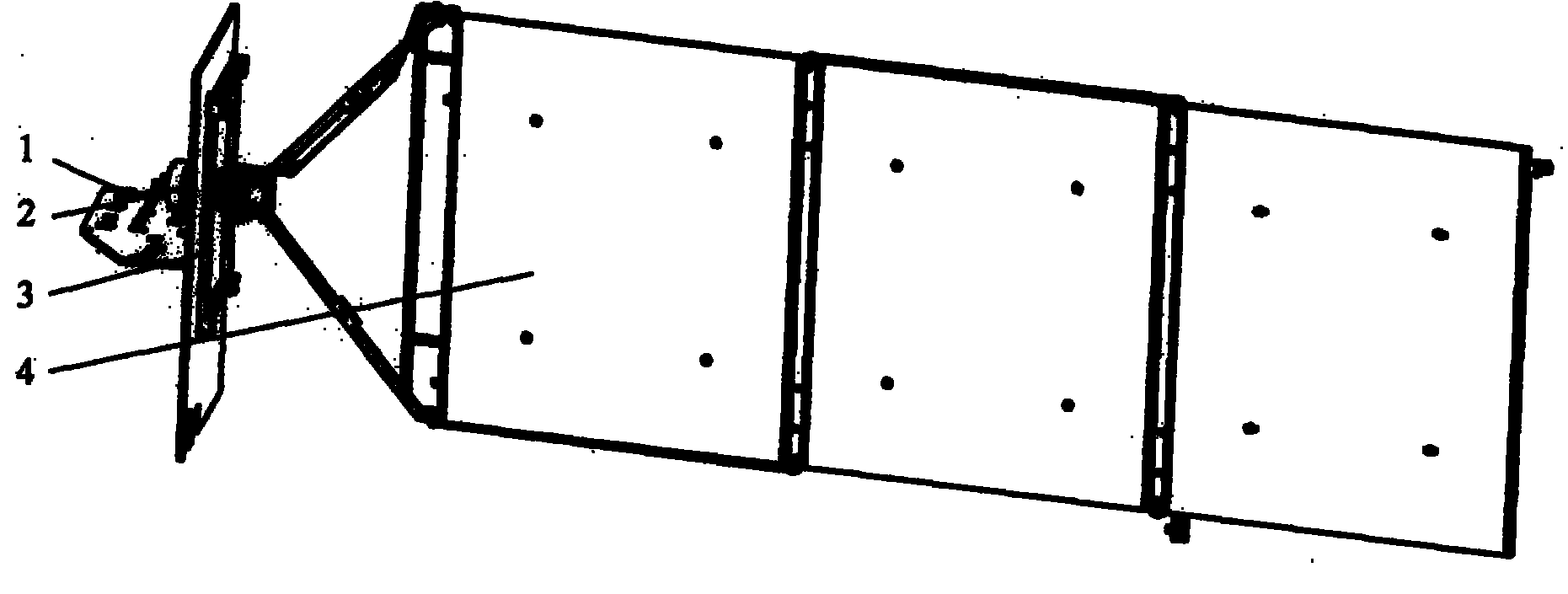

[0017] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0018] Brief introduction to the theoretical analysis basis of the present invention is as follows:

[0019] After the solar cell array is assembled, if the assembly stress introduced by the interface error of the final assembly docking surface and exerted on the solar cell array drive mechanism is less than its allowable assembly stress, it can be considered that the solar cell array drive mechanism has achieved stress-free installation. .

[0020] According to the requirements of six degrees of freedom when the solar cell array driving mechanism is installed, Table 1 shows the adaptability analysis of the solar cell array to the deviation. According to the analysis, the stress-free installation method of the solar cell array driving mechanism is formulated as follows.

[0021] Table 1 Adaptability analysis of solar cell array to BAPTA installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com