Inlet temperature control device for postprocessor of engine based on phase-change materials

A post-processor and phase-change material technology, which is applied to the electronic control of exhaust treatment devices, engine components, combustion engines, etc., can solve the problem of high ambient temperature and achieve the effect of recycling and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

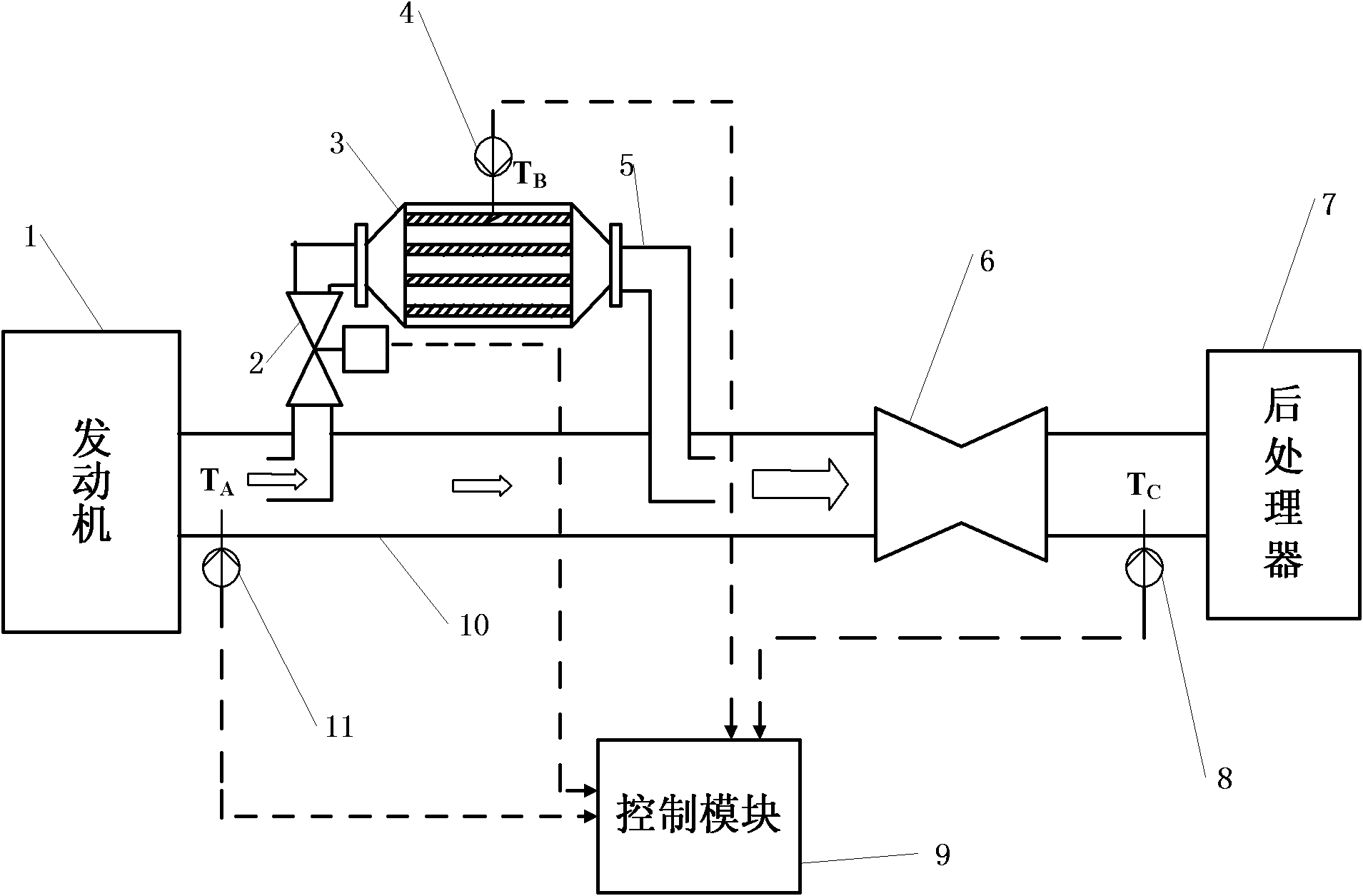

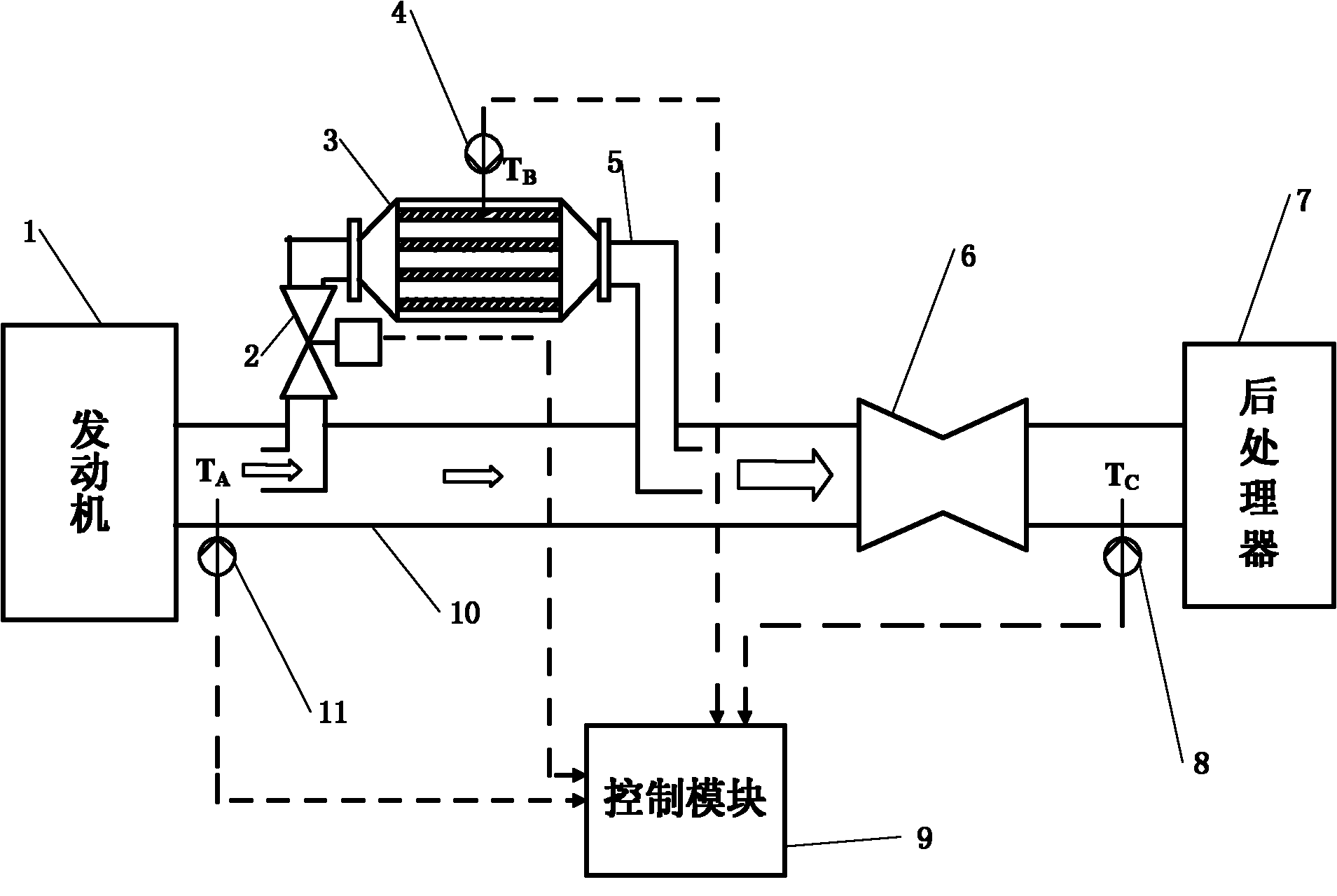

[0017] The present invention consists of engine 1, proportional control valve 2, phase change heat exchanger 3, temperature sensor II 4, U-shaped exhaust pipe 5, mixer 6, post processor 7, temperature sensor III 8, control module 9, main exhaust Pipe 10, temperature sensor I 11, wherein the main exhaust pipe 10 of engine 1 is connected with postprocessor 7 through mixer 6; Phase-change heat exchanger 3 is connected between the inlet pipe and the outlet pipe of U-shaped exhaust pipe 5 The air inlet of intake pipe in the U-shaped exhaust pipe 5 and the air outlet of air outlet pipe are reversely set, and are placed in the main exhaust pipe 10 before the mixer 6, and the air inlet pipe and the air outlet pipe are connected with the main exhaust pipe 10 The parts in contact are sealed and fixed; the air inlet of the intake pipe in the U-shaped exhaust pipe 5 faces opposite to the flow direction of the exhaust gas in the main exhaust pipe 10; The flow direction of exhaust gas in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com