Method of dispensing fluorescent glue on LED (light-emitting diode) based on COB (Chip On Board) technology

A fluorescent glue, LED chip technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of inability to use PCB substrates, poor color temperature uniformity, etc., and achieve the effect of saving materials, good color temperature uniformity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

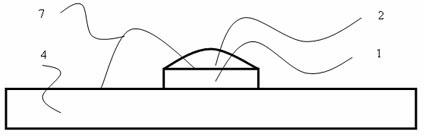

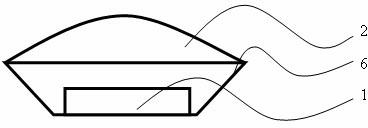

[0031] Embodiment 1: A method of spotting fluorescent glue on LED based on COB technology, the specific implementation process is as follows:

[0032] 1. Determination of the amount of fluorescent glue dispensing

[0033] The size of the LED chip 1 and the dispensing amount of the fluorescent glue 2 determine the shape of the fluorescent glue 2, and the shape of the fluorescent glue 2 and the color temperature of the white light emitted by the LED chip 1 after dispensing determine the uniformity of the color temperature of the white light at different angles. According to the selection of LED chip 1, under the specified color temperature requirements, find out the appropriate dispensing amount of fluorescent glue 2, so that the LED chip 1 after dispensing has the best color temperature uniformity at different emission angles.

[0034] 2. Determination of phosphor and silica gel

[0035] For a certain type of LED chip 1, phosphor and silica gel, after determining the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com