Energy-saving and environment-friendly automatic disassembly and separation system for waste batteries

A waste battery, energy saving and environmental protection technology, applied in battery recycling, solid waste removal, waste collector recycling, etc., can solve the problems of high labor intensity, high energy consumption in smelting, unclean and environmentally friendly processes, and reduce energy consumption in smelting , reduce pollution emissions, improve the effect of dismantling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

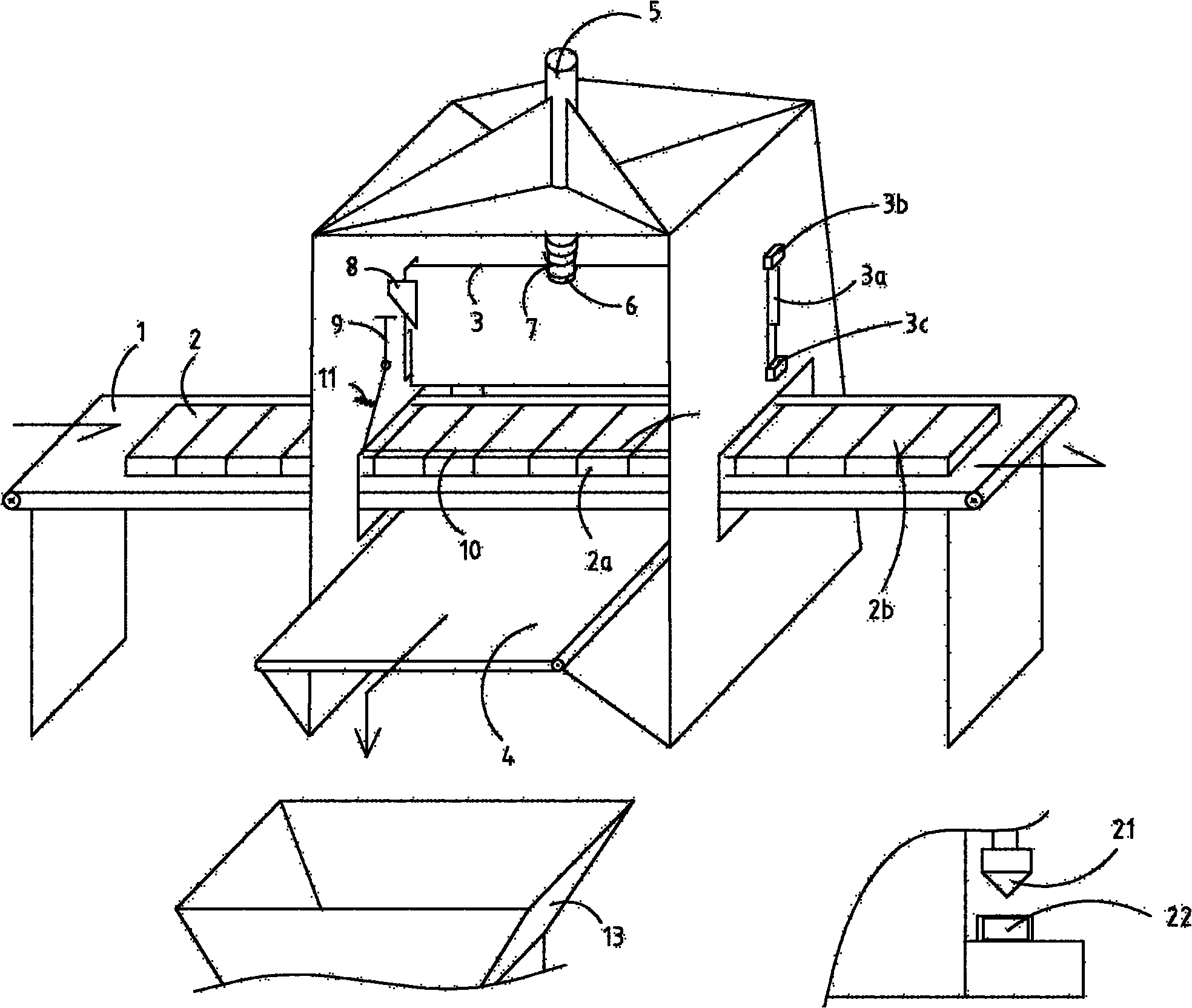

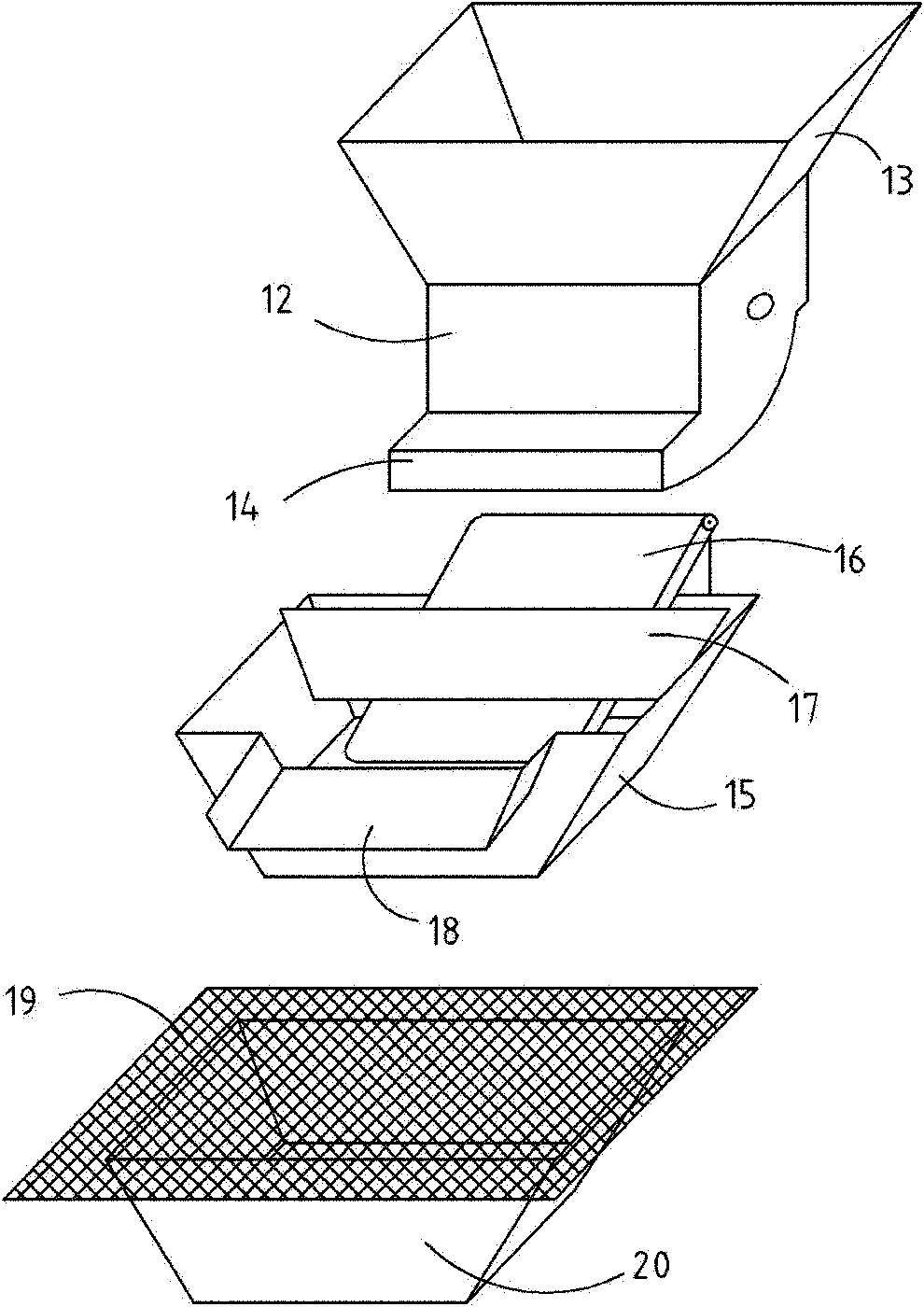

[0022] see figure 1 , in this embodiment, the storage battery transmission belt 1 is arranged horizontally, and each storage battery 2 is arranged on the storage battery transmission belt 1 in the same direction according to the battery box cover 2a, and is transmitted from left to right along with the storage battery transmission belt 1; A cutting mechanism is arranged above the cutting mechanism, and the cutting knife 3 that can move up and down in the cutting mechanism to form a cutting action is on the longitudinal position of the junction of the battery box cover 2a and the battery body 2b; the box cover conveyor belt 4 is set below the cutting machine, The conveying direction of accumulator case cover conveyer belt 4 and accumulator conveyer belt 1 is perpendicular.

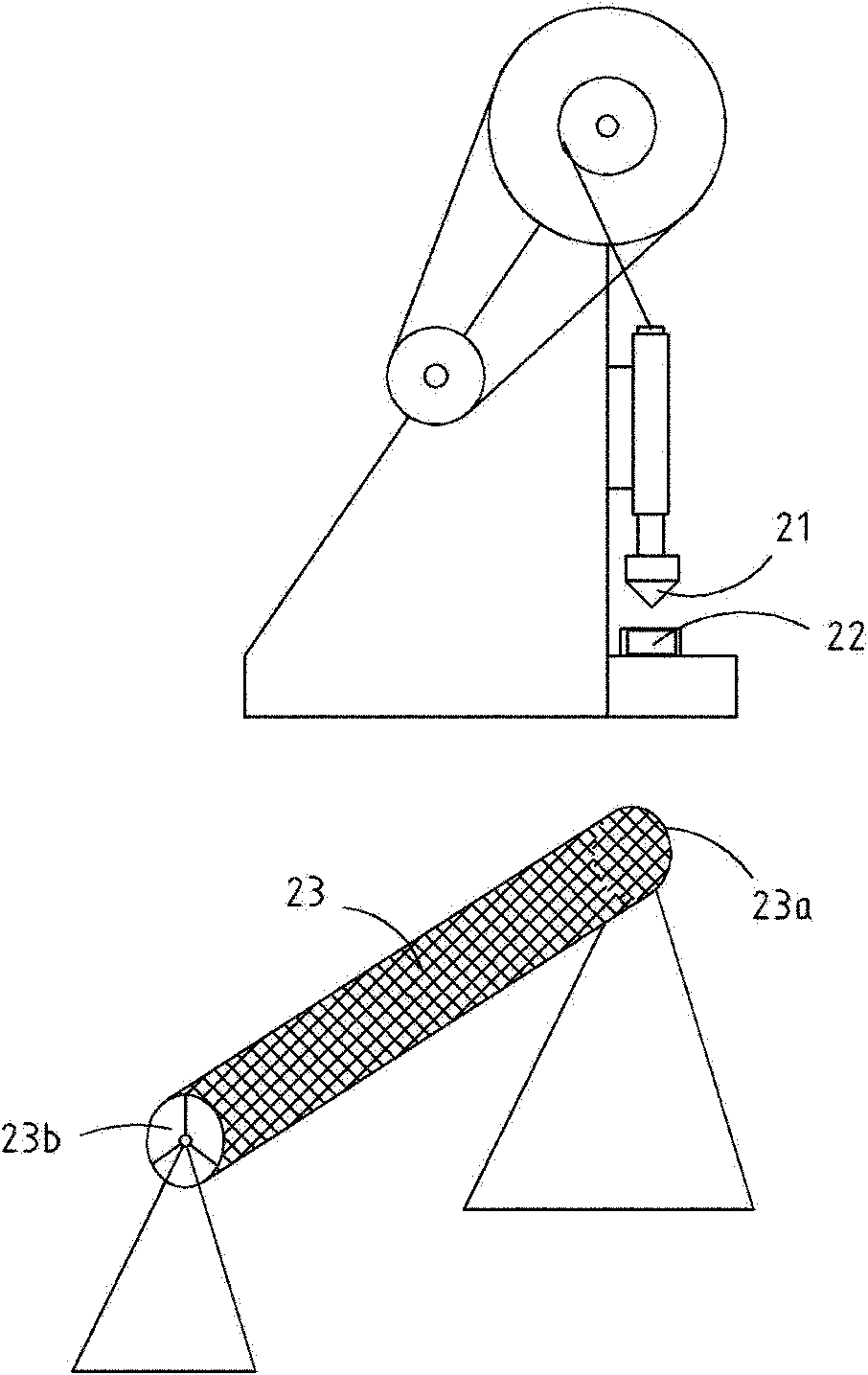

[0023] figure 1 As shown, the cutting knife 3 is driven by a hydraulic cylinder 5 and a transmission member by a hydraulic rod 6, and a hydraulic rod return spring 7 is arranged on the hydraulic rod 6. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com