Compulsive air-cooling lower electrode specially used for resistance projection welding of annular nut

A ring nut and electrode technology, applied in the direction of resistance welding equipment, electrode features, manufacturing tools, etc., can solve the problems of affecting positioning accuracy and welding quality, affecting assembly quality, poor positioning accuracy, etc., to avoid excessive local current, ideal Engineering practicability, effect of reducing adhesion of spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The shape, structure, material, working principle and usage method of each component involved in the present invention will be further elaborated below by referring to the accompanying drawings and describing specific embodiments.

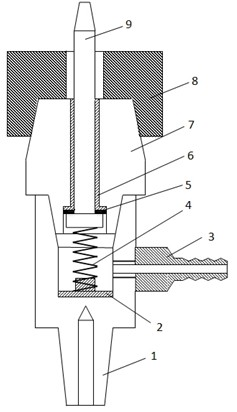

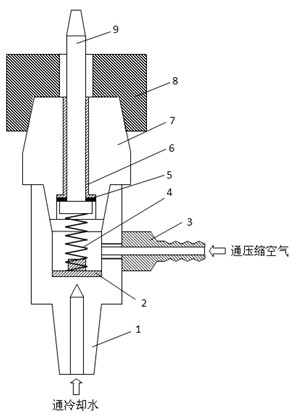

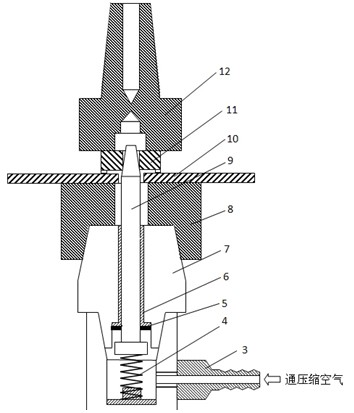

[0019] The basic structure of the lower electrode involved in the present invention is as follows: figure 1 and figure 2 As shown, three parts including the lower body 1 of the lower electrode holder, the upper body 7 of the lower electrode holder and the electrode cap 8 are all made of chrome-zirconium copper.

[0020] There is a circular electrode seat cavity in the upper part of the lower electrode seat lower body 1, and an insulating gasket 2 is installed in it to isolate the electrical connection with the lower electrode seat lower body 1. The insulating gasket 2 can be made of ceramic material or other insulating materials. The outer side of the cavity of the electrode holder is connected with a ventilation joint to introduce compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com