Fixing device assisting multi-wire cutting machine in cutting of silicon single crystal rods

A multi-wire cutting machine and fixing device technology, applied in the direction of fine working devices, working accessories, stone processing equipment, etc. The yield is improved, the product quality is beneficial, and the effect of solving the deformation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

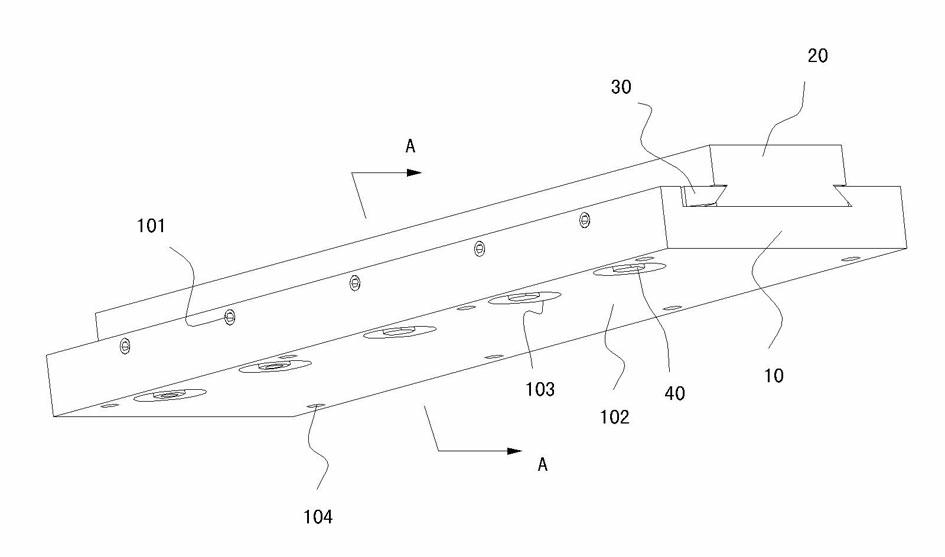

[0015] see figure 1 . The device is composed of three parts: bonding plate 10 , bonding strip 20 and locking strip 30 . The adhesive plate 10 is a rectangular plate with a flat bottom surface and a concave groove on the top surface. Among the two side walls of the concave groove, the right side wall is a dovetail wall, and the left side wall is a right-angle wall. Relative to the locking bar 30, there is a through hole 103 with a "convex" shape in the vertical direction, and a threaded through hole 106 for receiving the fastening bolt 101 in the horizontal direction.

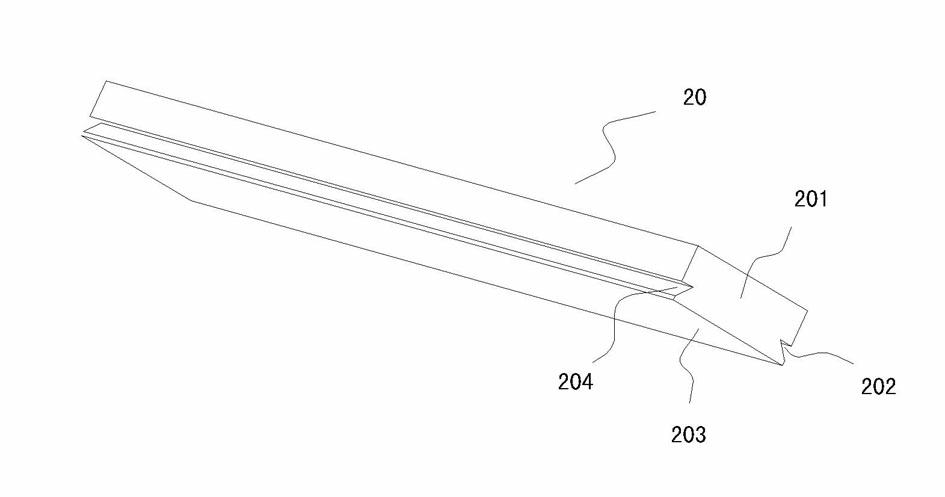

[0016] combine figure 2 . The adhesive strip 20 is a rectangular plate with a flat top and bottom, and a dovetail groove 202 is formed on the lower part of the plate, and the dovetail slope 204 is downward.

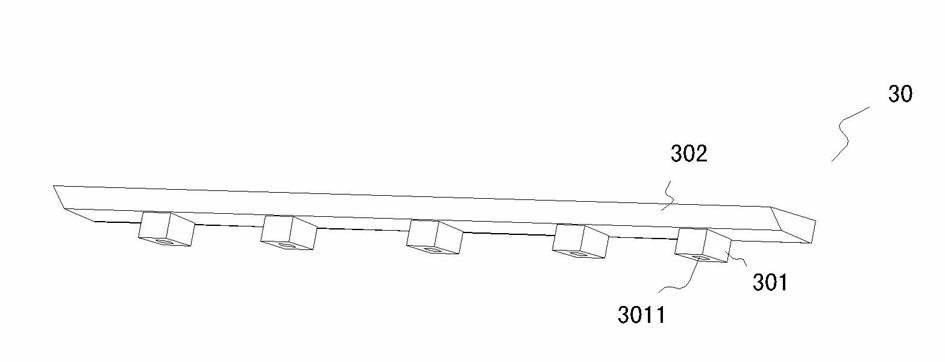

[0017] combine image 3 . The length of the locking strip 30 is consistent with that of the adhesive strip 20 , and a slope matching the dovetail slope 204 of the adhesive strip 20 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com