Co-extruded and bidirectional-stretched composite film and preparation method thereof

A composite film and two-way stretching technology, which is applied in the direction of chemical instruments and methods, flat products, and other household appliances, can solve the problems affecting the gas barrier properties, shape stability and transparency of laminated products, general tensile strength, optical properties, etc. Poor performance and other problems, to achieve the effect of small thickness, excellent antistatic performance and high barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

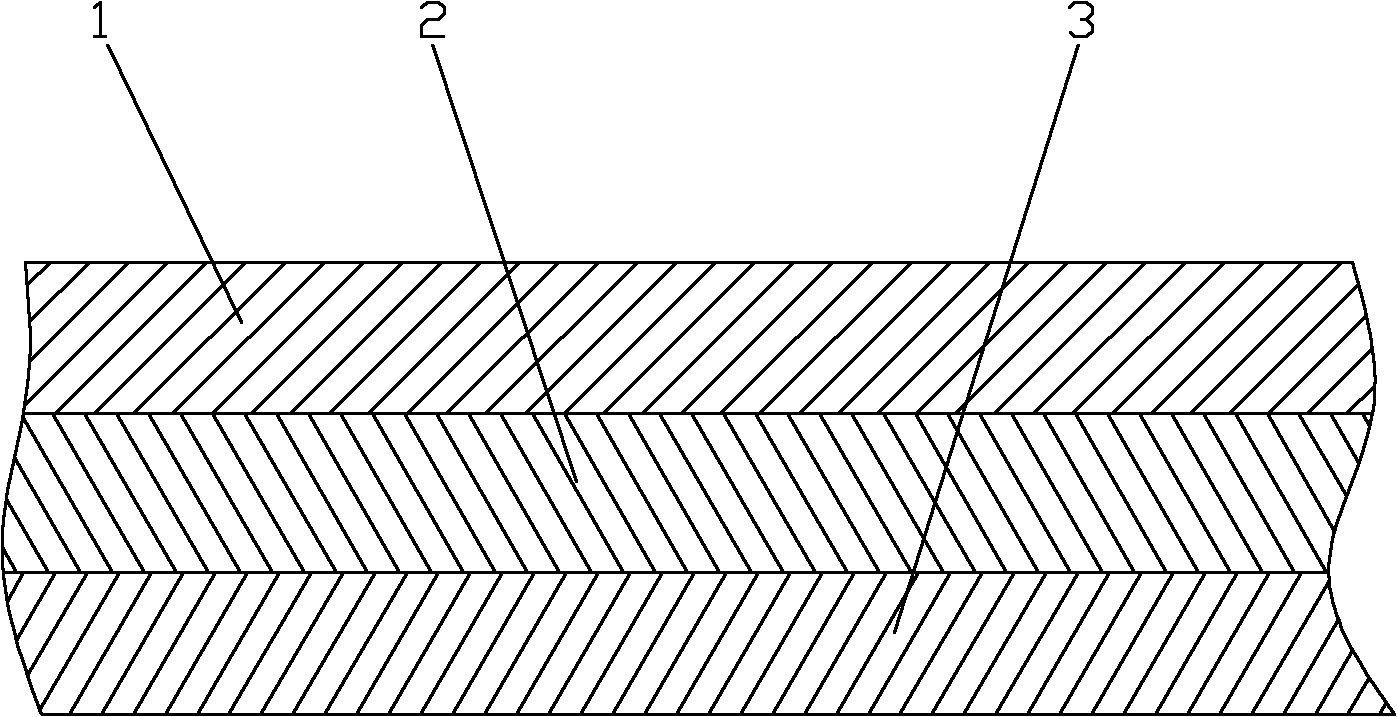

[0030] The composite film of the present invention has a three-layer structure, and each layer is an auxiliary barrier layer 1 of a copolymerized polypropylene resin, an auxiliary barrier layer 2 of a homopolypropylene resin containing an adhesive resin, and a main barrier layer 3 of an ethylene-vinyl alcohol copolymer resin. , the composite film is formed by two-way stretching after co-extrusion of a three-layer structure. The molar content of ethylene in the ethylene-vinyl alcohol copolymer resin of the present invention is 38%.

[0031] The adhesive resin of the present invention is an anhydride-modified polypropylene adhesive resin, which accounts for 20% of the total weight of the homopolymerized or copolymerized polypropylene resin containing the adhesive resin.

[0032] The copolymerized polypropylene resin 1 and the homopolymerized polypropylene resin 2 containing adhesive resin of the present invention respectively contain 0.2%-20% by weight of functional masterbatch....

Embodiment 2

[0035] The composite film of the present invention has a three-layer structure, and each layer is an auxiliary barrier layer 1 of homopolypropylene resin, an auxiliary barrier layer 2 of homopolypropylene resin containing adhesive resin, and a main barrier layer of ethylene-vinyl alcohol copolymer resin. 3. The composite film is co-extruded with a three-layer structure and then biaxially stretched. The molar content of ethylene in the ethylene-vinyl alcohol copolymer resin of the present invention is 32%.

[0036] The adhesive resin of the present invention is an anhydride-modified polypropylene adhesive resin, which accounts for 5% of the total weight of the homopolymerized or copolymerized polypropylene resin containing the adhesive resin.

[0037] The homopolypropylene resin 1 and the homopolypropylene resin 2 containing adhesive resin of the present invention respectively contain 0.2%-20% by weight of functional masterbatch. The functional masterbatch is a filler masterba...

Embodiment 3

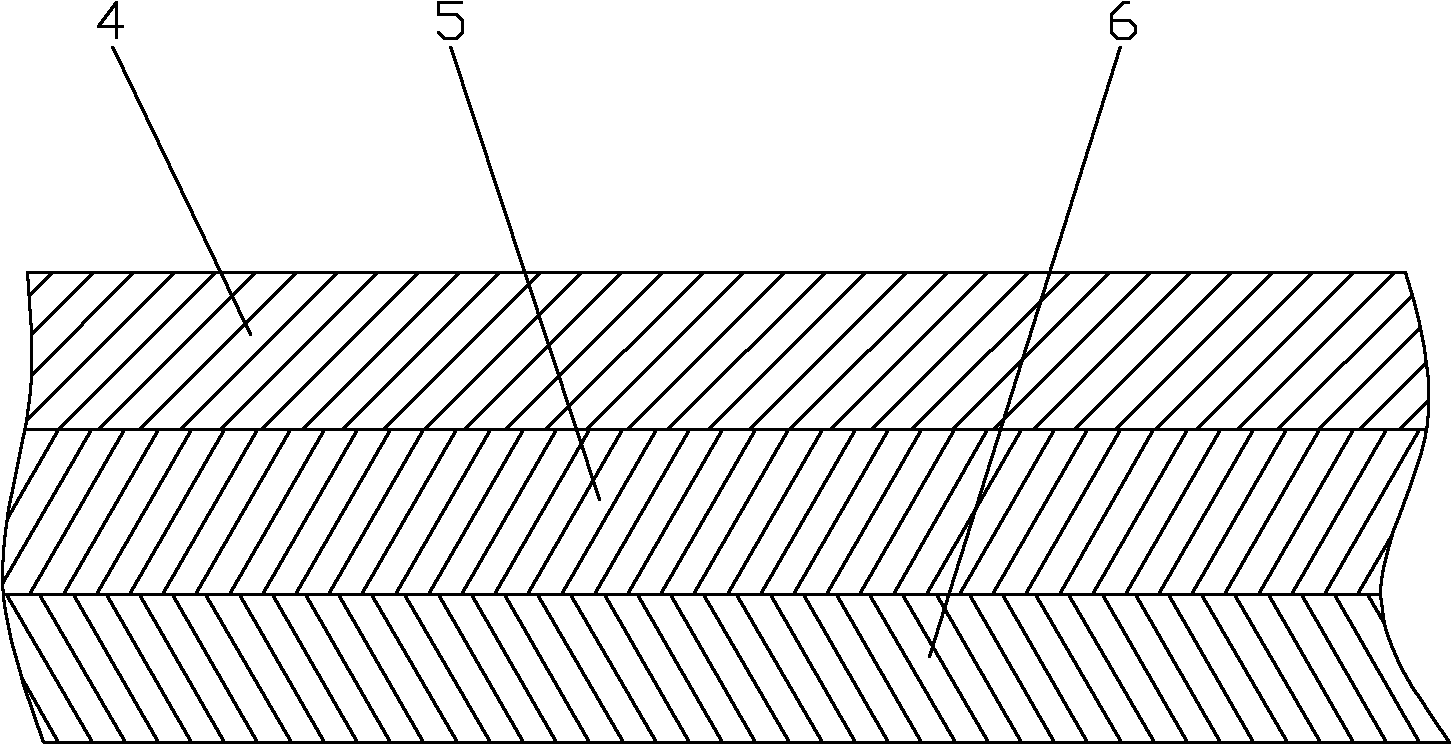

[0040] The composite film of the present invention has a three-layer structure, and each layer is an auxiliary barrier layer of homopolypropylene resin 4, a main barrier layer 5 of ethylene-vinyl alcohol copolymer resin, and an auxiliary barrier layer of homopolypropylene resin containing adhesive resin 6. The composite film is co-extruded with a three-layer structure and then biaxially stretched. The molar content of ethylene in the ethylene-vinyl alcohol copolymer resin of the present invention is 40%.

[0041] The adhesive resin of the present invention is an anhydride-modified polypropylene adhesive resin, which accounts for 15% of the total weight of the homopolymerized or copolymerized polypropylene resin containing the adhesive resin.

[0042] The homopolypropylene resin 4 and the homopolypropylene resin 6 containing adhesive resin of the present invention respectively contain 0.2%-20% by weight of functional masterbatch. The functional masterbatch is smooth masterbatc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com