Cement liquid grinding aid and preparation method thereof

A grinding aid and liquid technology, applied in the field of cement liquid grinding aid and its preparation, can solve the problem that cement fineness and specific surface area need to be improved urgently, cement grinding energy consumption is not significantly improved, and strength cannot be significantly improved, etc. problems, to achieve the effect of improving grinding aid, improving fineness and specific surface area, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

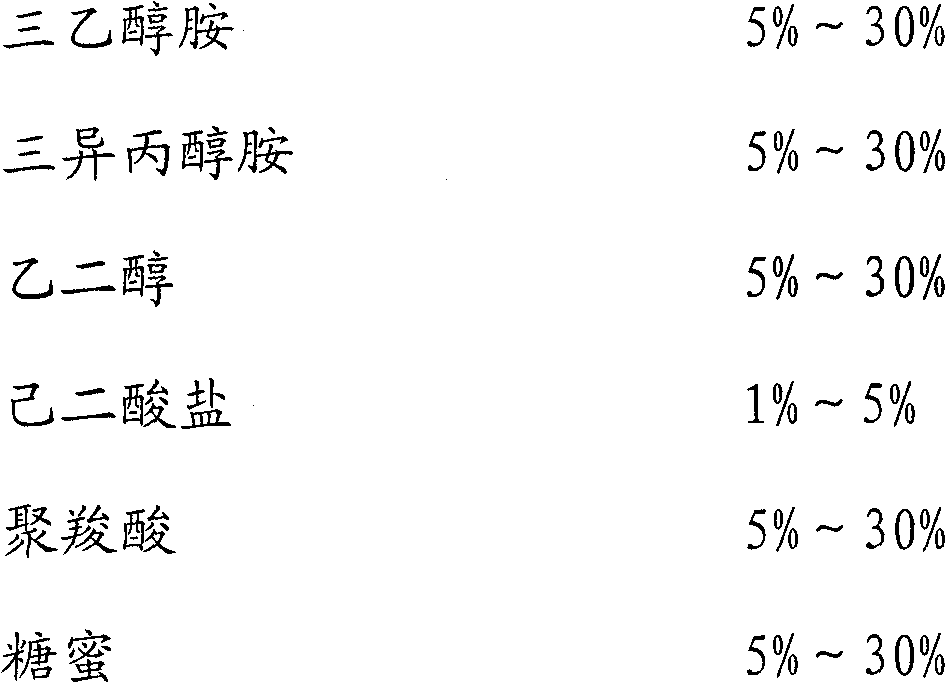

Embodiment 1

[0035] Embodiment 1: used cement liquid grinding aid is made up of triethanolamine, triisopropanolamine, ethylene glycol, adipate, polycarboxylic acid, molasses and water, and the weight percent of each component is as follows: triethanolamine 15%, triisopropanolamine 15%, ethylene glycol 10%, adipate 1%, polycarboxylic acid 20%, molasses 5%, and the rest is water. The water used therein is common tap water, and other components are all commercially available. The preparation steps are as follows: add ordinary tap water into the reaction kettle; add molasses, adipate, triethanolamine, triisopropanolamine, ethylene glycol and polycarboxylic acid to the reaction kettle sequentially while stirring; add all components After that, stir for 15 minutes; obtain cement liquid grinding aid.

Embodiment 2

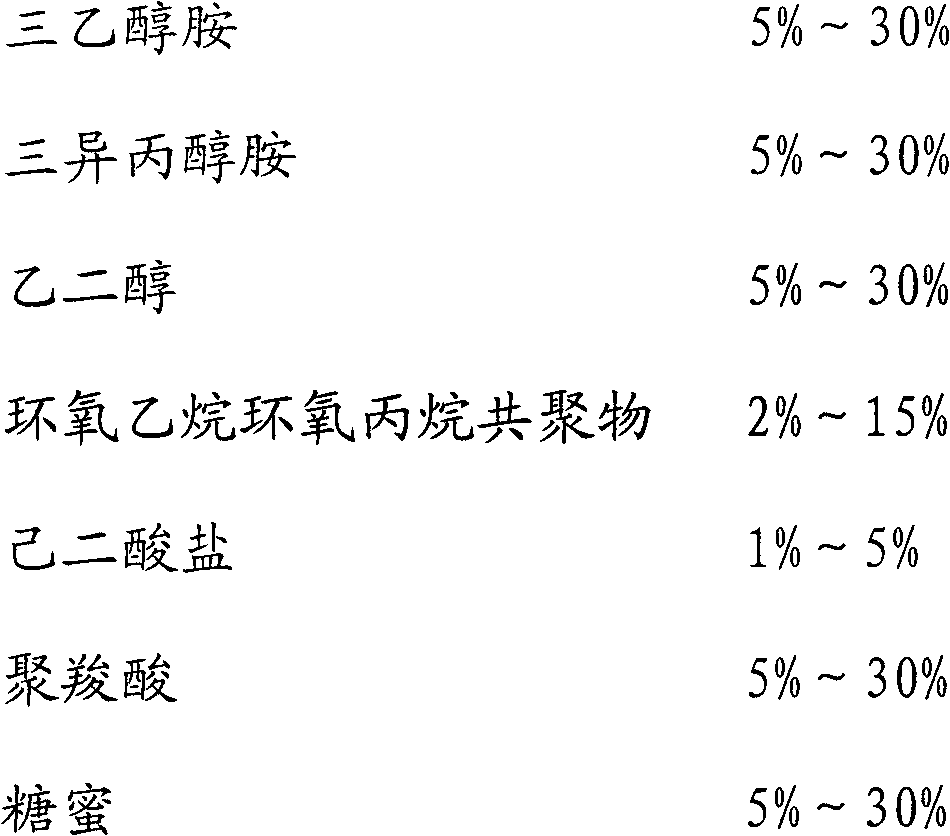

[0036] Embodiment 2: used cement liquid grinding aid is made up of triethanolamine, triisopropanolamine, ethylene glycol, ethylene oxide propylene oxide copolymer, adipate, polycarboxylic acid, molasses and water, The weight percent of each component is as follows: triethanolamine 30%, triisopropanolamine 10%, ethylene glycol 5%, ethylene oxide propylene oxide copolymer 2%, adipate 1%, polycarboxylic acid 5% %, molasses 5%, and the rest is water. The water used therein is common tap water, and other components are all commercially available. The preparation steps are: add ordinary tap water into the reaction kettle; add molasses, adipate, triethanolamine, triisopropanolamine, ethylene glycol and polycarboxylic acid to the reaction kettle sequentially while stirring; add all the components Finally, stir for 15 minutes; the grinding aid liquid obtained after stirring and the ethylene oxide propylene oxide copolymer are emulsified and dispersed through an emulsifier; a highly un...

Embodiment 3

[0037] Embodiment 3: used cement liquid grinding aid is made up of triethanolamine, triisopropanolamine, ethylene glycol, ethylene oxide propylene oxide copolymer, adipate, polycarboxylic acid, molasses and water etc., The weight percentages of each component are as follows: 15% triethanolamine, 25% triisopropanolamine, 3% ethylene glycol, 3% ethylene oxide propylene oxide copolymer, 2% adipate, 5% polycarboxylic acid , molasses 5%, and the rest is water. The water used therein is common tap water, and other components are all commercially available. The preparation steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com