Simulator for aerobic high-temperature composting of solid waste

A technology of solid waste and high-temperature composting, which is applied in fertilization devices, organic fertilizers, and the preparation of organic fertilizers. It can solve the problems of inconvenient composting tests, large floor space, and complex design, and achieves good simulation results. small, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

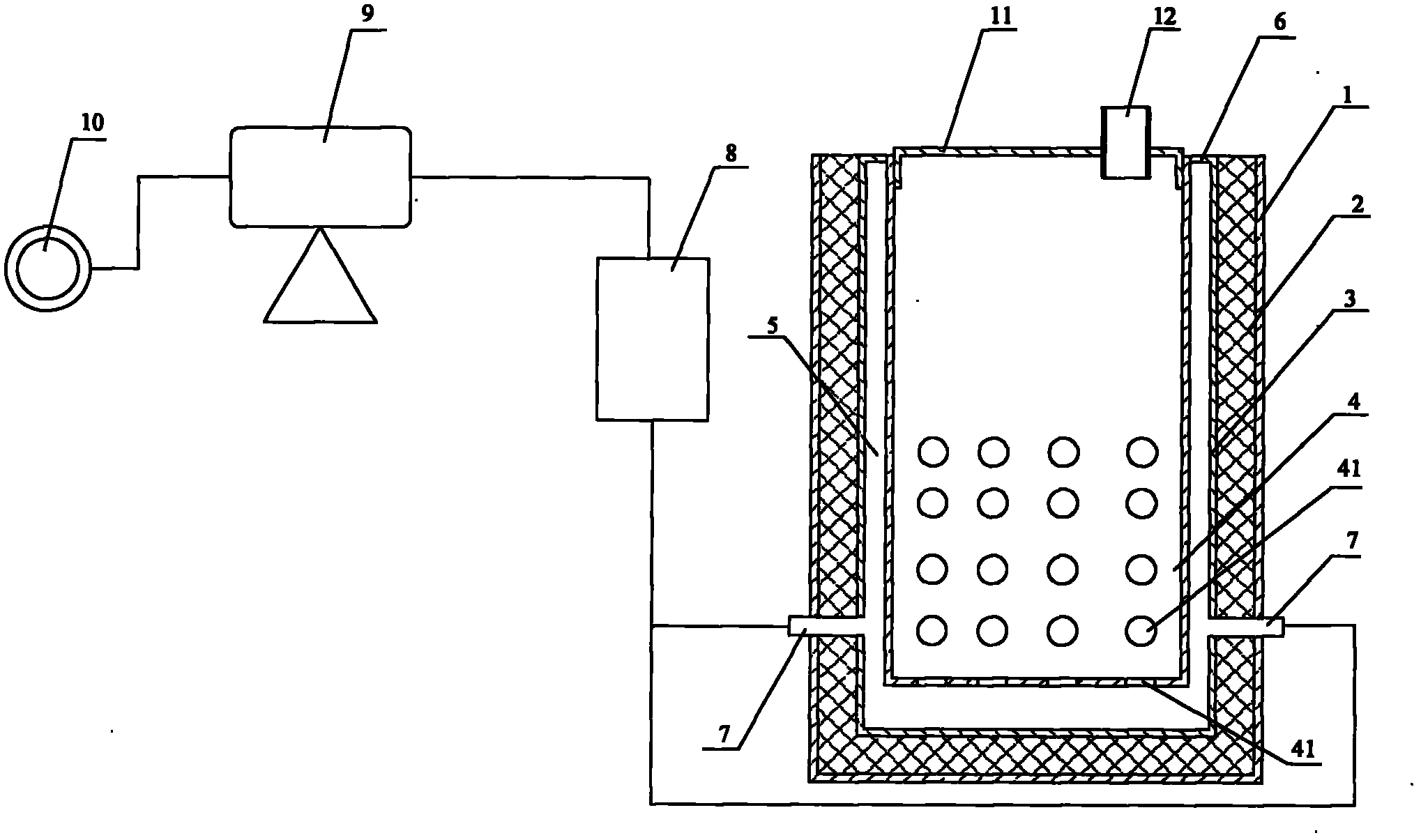

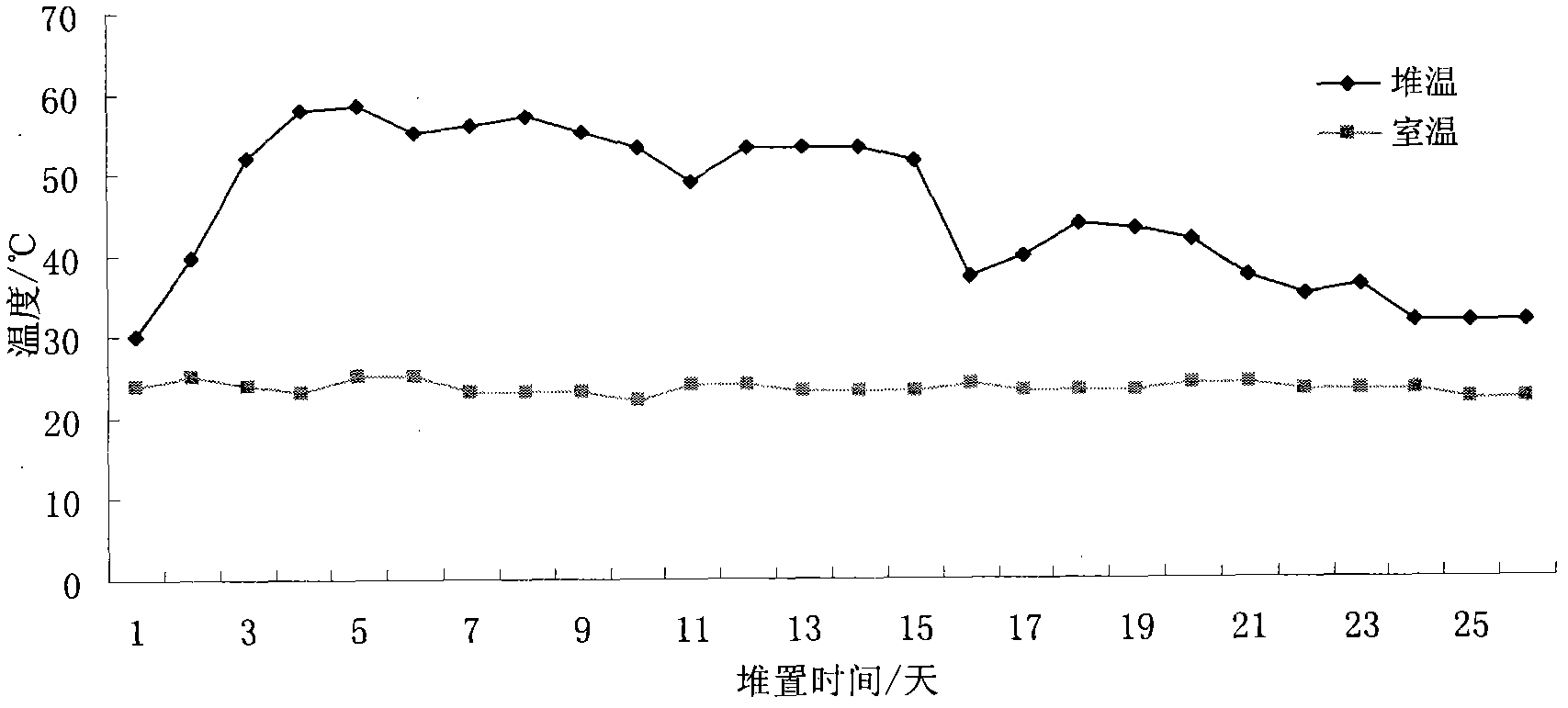

[0025] Embodiment 1, Figure 1 ~ Figure 2 Combined with a solid waste aerobic high-temperature composting simulation device, including compost ventilation control system and compost bucket components.

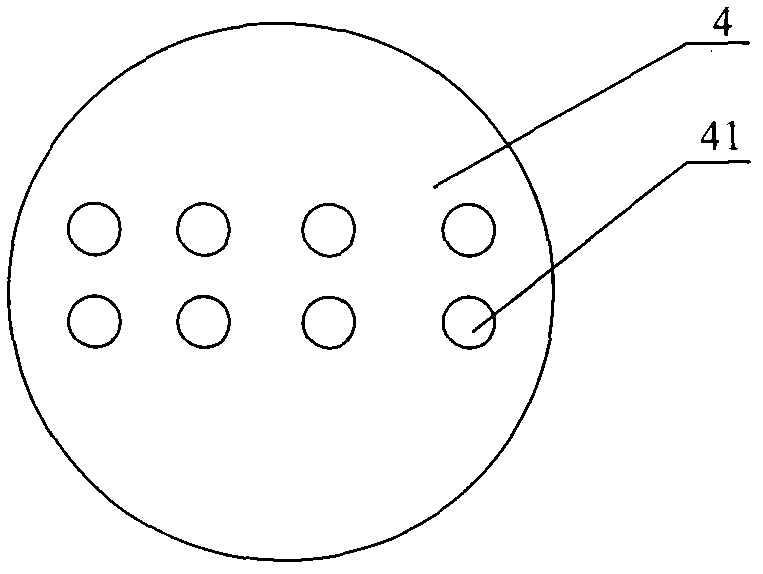

[0026] The compost bucket assembly includes an outer bucket 3 and an inner bucket 4 set in the inner cavity of the outer bucket 3. The central axis of the outer bucket 3 coincides with the central axis of the inner bucket 4, and the inner wall of the outer bucket 3 is aligned with the inner wall. The distance between the outer walls of the barrel 4 is 1-3 cm. Both the outer layer barrel 3 and the inner layer barrel 4 are barrel bodies with a bottom and no top. An openable bung 11 is arranged on the top of the inner barrel 4, specifically: an internal thread is set on the top of the inner wall of the inner barrel 4, and an external thread matching the internal thread is set on the bung 11; relying on the internal thread In connection with the external thread, the top of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com