Device and method for cleaning greasy dirt on surface of large-coil nickel strap

A technology for cleaning device and surface oil stains, which is applied in the field of surface oil stain cleaning devices for large-volume nickel strips, which can solve the problems that nickel strips cannot be cleaned in time and thoroughly, and achieve the effects of simple structure, low cost, and economical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

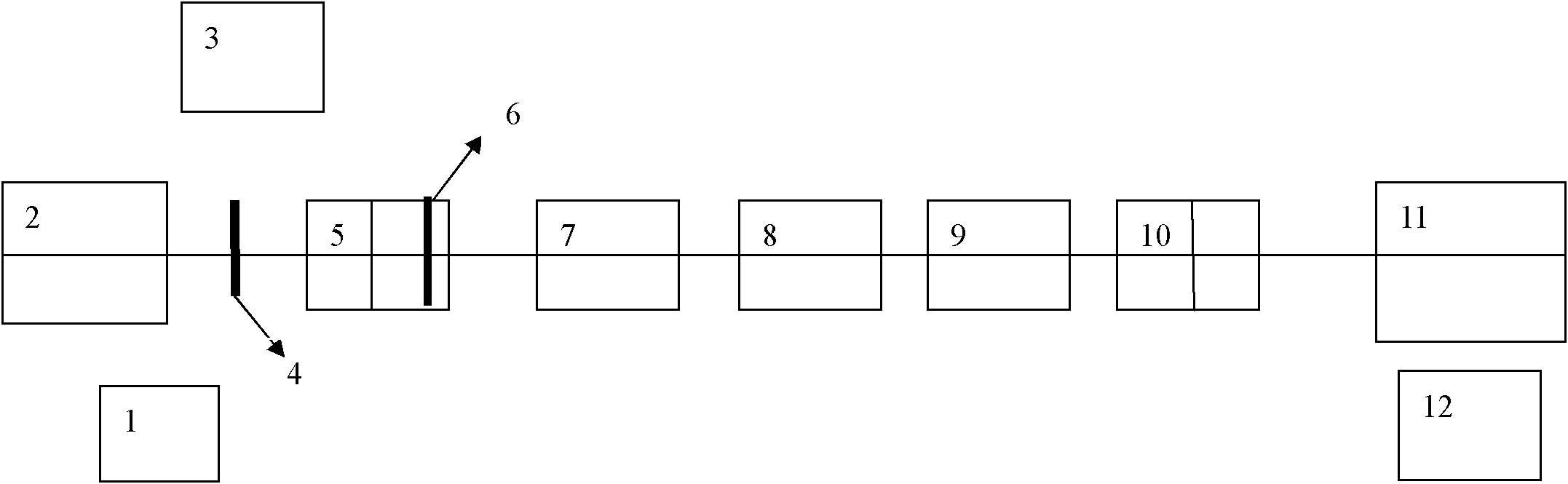

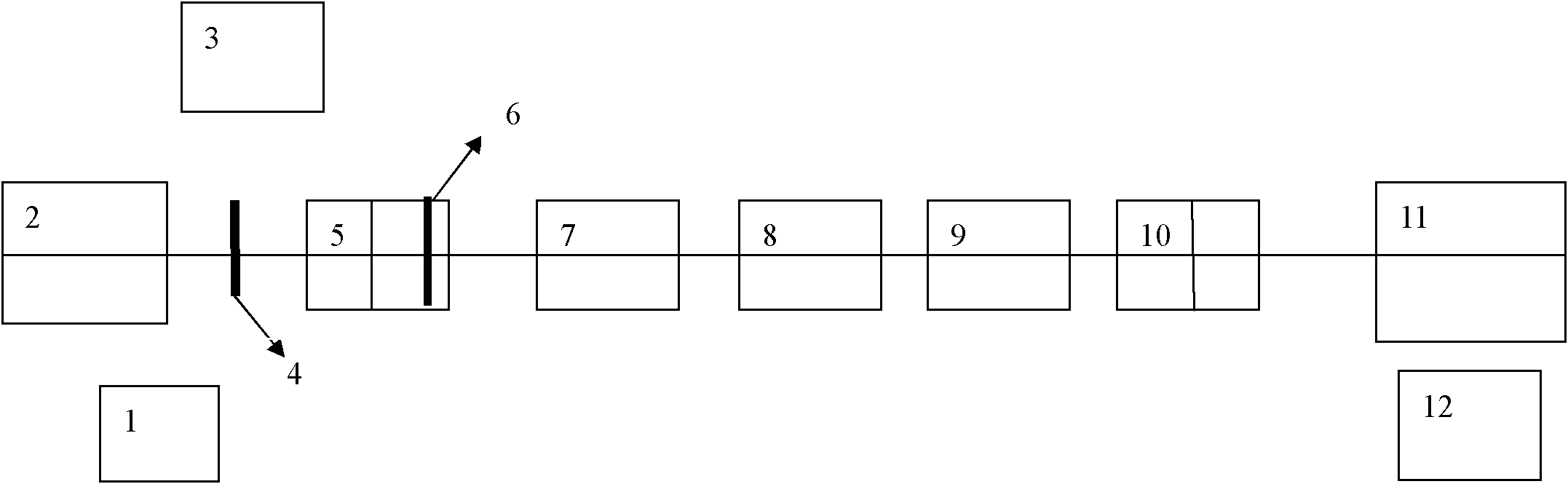

[0021] like figure 1 Shown, a kind of large roll nickel strip surface oil cleaning device, it comprises unwinder 2, spray device 6, closed cleaning device 7, hydrocarbon cleaning device 8 and winder 11, described unwinder 2 , spray device 6, closed cleaning device 7, hydrocarbon cleaning device 8 and winder 11 are arranged in sequence, and the unwinder 2 is equipped with a large roll of nickel strip, and the nickel strip released by the unwinder 2 passes through the spray device 6 in sequence , closed cleaning device 7 and hydrocarbon cleaning device 8 to winder 11 for winding.

[0022] The present invention also includes a wool felt positioning device 4, an S-shaped pressing roller 5, a drying device 9 and an S-shaped guide roller 10, and the wool felt positioning device 4 and the S-shaped pressing roller 5 are sequentially arranged after the unwinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com