Construction method of large-span asymmetrical double-arch railway tunnel under terrain bias pressure condition

A tunnel construction, asymmetric technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of large-area cracks in the lining, high engineering cost, and single construction method, so as to shorten the construction period, improve the construction efficiency, and simplify the construction. Effects of construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

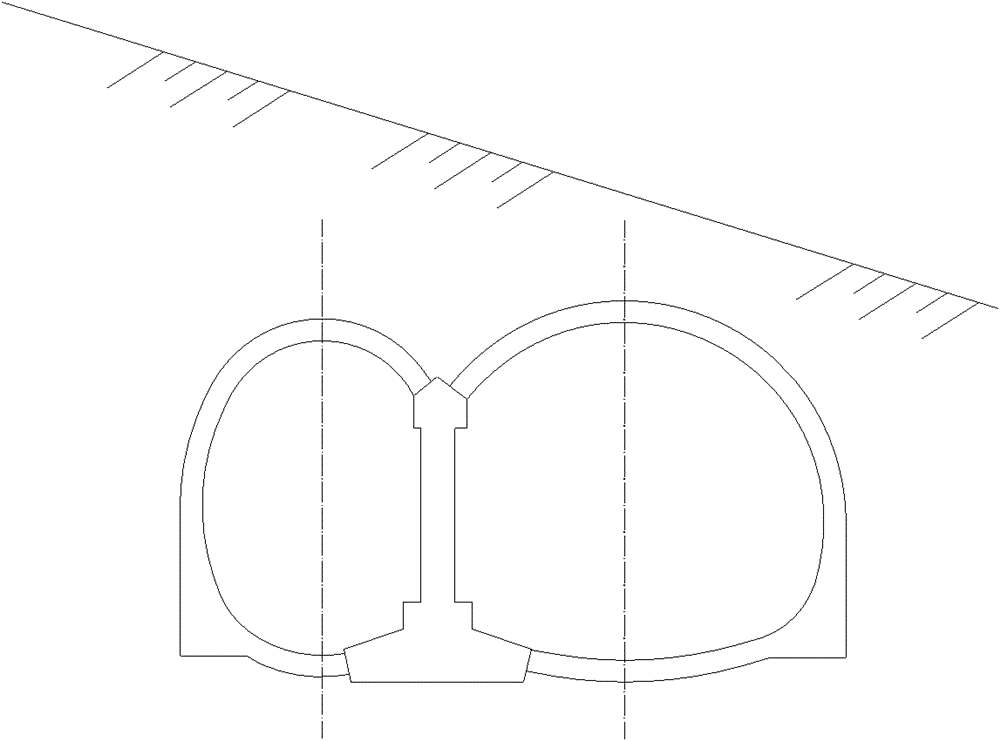

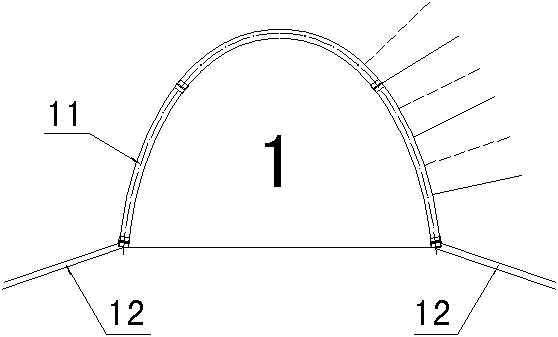

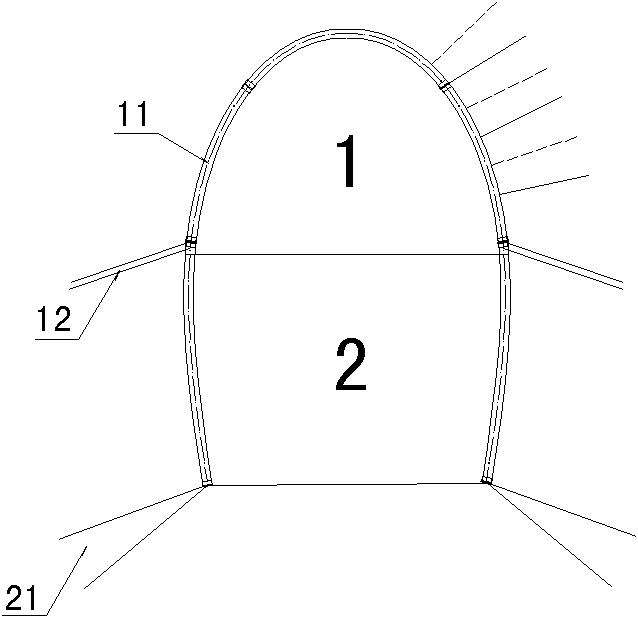

[0015] refer to figure 1 , the long-span asymmetric double-arch railway tunnel is structurally composed of an inner cavern, a middle partition wall and an outer cavern. The construction method of the large-span asymmetrical double-arch railway tunnel under the terrain bias condition of the present invention comprises the following steps:

[0016] ① The pilot tunnel is excavated by steps, and the initial support of the pilot tunnel is implemented around the pilot tunnel;

[0017] ② After the central pilot tunnel is penetrated, pour the central partition wall backward along the tunnel axis toward the entrance, and after it reaches the design strength, set up temporary cross braces between the central partition wall of the outer cavern and the initial support of the central pilot tunnel;

[0018] ③ The inner cavern is excavated by steps, and the initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com